Method for preparing nano-array patterns by icp etching gan-based multiple quantum wells

A nano-array and nano-pattern technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as substrate material and structural damage, and achieve the effects of reducing etching, reducing losses, and promoting chemical reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

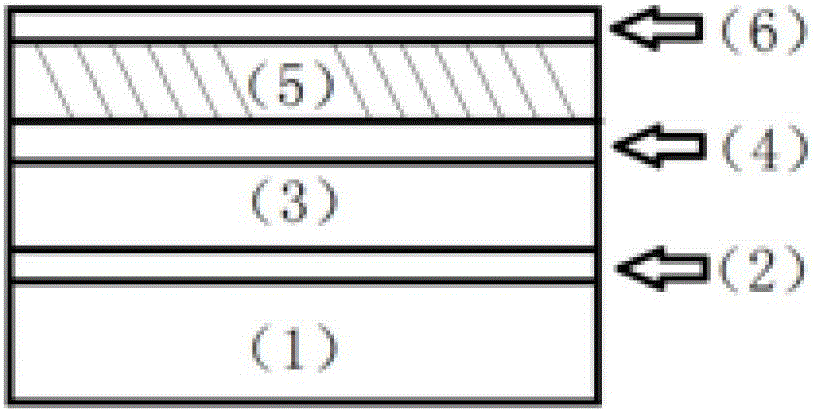

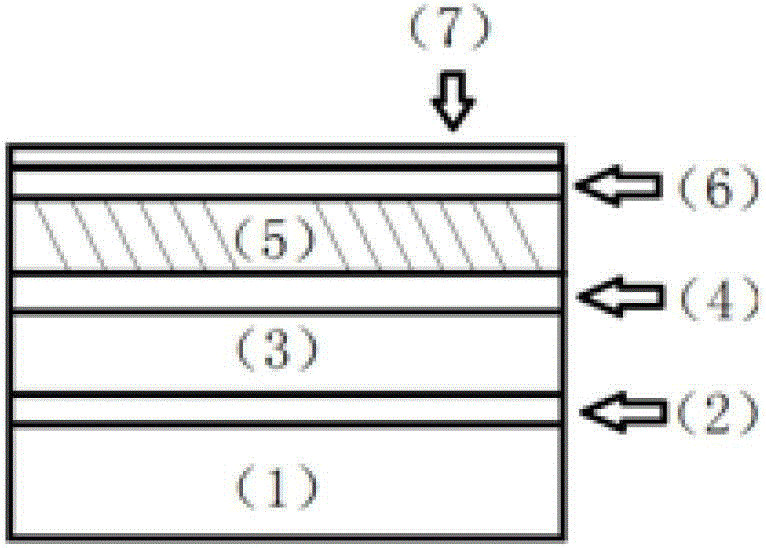

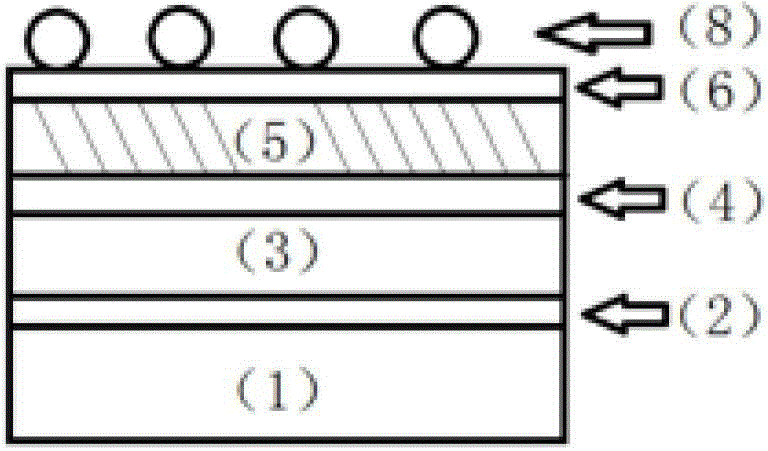

[0063] refer to Figure 1-Figure 5 As shown, the present invention provides a GaN-based multi-quantum well nanometer light-emitting array device, comprising the following steps:

[0064] Step 1: Take a sapphire substrate 1 with a thickness of 300um.

[0065]Step 2: epitaxially grow a GaN buffer layer 2 with a thickness of 30nm, a non-doped GaN layer 3 with a thickness of 2um, an n-type GaN layer 4 with a thickness of 500nm, and an InGaN / GaN quantum well layer with a thickness of 100nm on a sapphire substrate 1 by ThomasSwan MOCVD and a 200nm thick p-type GaN layer 6, wherein the InGaN / GaN quantum well layer 5 is alternately grown indium gallium nitride / gallium nitride, the entire thickness is about 100nm, the period number is 5, and the In composition is 0.18. Ga source, In source and N source are trimethyl gallium, trimethyl indium and liquid ammonia (blue ammonia) respectively.

[0066] Step 3: Carry out PVD vacuum evaporation of Ni metal on the p-type GaN layer 6 using PV...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com