Double-layer frequency selection surface wave filter with frequency conversation function

A frequency selective surface and filter technology, applied in the microwave field, can solve the problems of not being able to shield, lose the stealth function, and the shielding room cannot choose different passband ranges, so as to achieve convenient operation, simple structure, and improve practical applicability and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

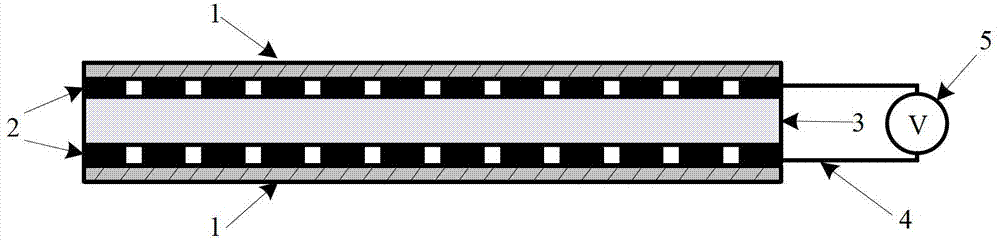

[0011] Specific implementation mode 1. Combination figure 1 Description of this embodiment, a double-layer frequency selective surface filter with frequency conversion function, including a frequency selective surface base layer 1, a frequency selective surface metal layer 2, a BST interlayer 3, a wire 4 and a voltage source 5; the BST interlayer 3 and the two The frequency selective surface metal layer 2 on the side is in close contact, and the frequency selective surface metal layer 2 is in close contact with the frequency selective surface base layer 1; the DC voltage source 5 is connected to the metal part of the frequency selective surface metal layer 2 through a wire 4.

[0012] The manufacturing method of the BST interlayer described in the present embodiment is:

[0013] Step 1, adding barium acetate, strontium acetate and titanium isopropoxide into acetic acid solution to dissolve respectively; mixing the three dissolved solutions to obtain barium strontium titanate s...

specific Embodiment approach 2

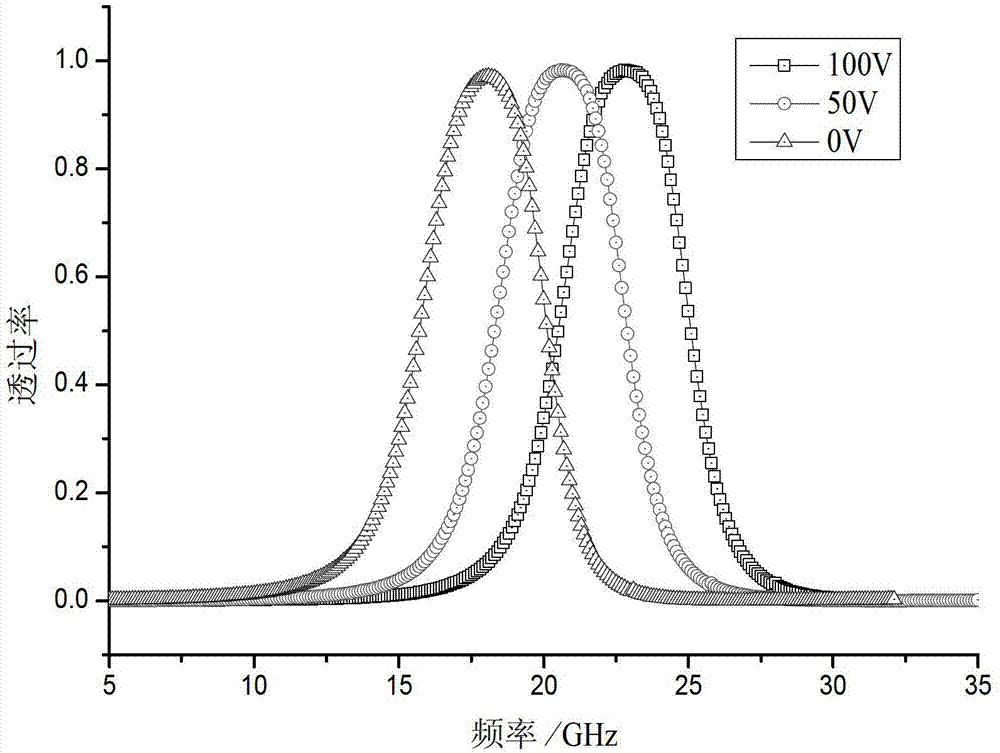

[0015] Specific embodiment two, combine figure 1 and figure 2 Describe this embodiment mode, this embodiment mode is the manufacturing method of a kind of double-layer frequency selective surface filter with frequency conversion function described in specific embodiment one, the BST material molecular formula required in this implementation is Ba 0.6 Sr 0.4 TiO 3 , according to the ratio relationship between the elements to prepare the amount of raw materials, including barium acetate, strontium acetate and titanium isopropoxide. Add barium acetate into the acetic acid solution, keep at 60°C for five minutes, then the barium acetate dissolves, add strontium acetate into the acetic acid solution, keep at 120°C for ten minutes, then dissolve the strontium acetate, add titanium isopropoxide to the acetic acid solution , and mix the three solutions to finally form a BST material; use the spin coating method to prepare the BST film, first introduce an appropriate amount of solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com