Method for stripping gas washing water

A technology of coal gas washing and water vapor, which is applied in the field of coal gasification technology, can solve the problems of sulfide stress corrosion cracking and chloride stress corrosion cracking, etc., and achieve the effects of alleviating stress corrosion, reducing material costs and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

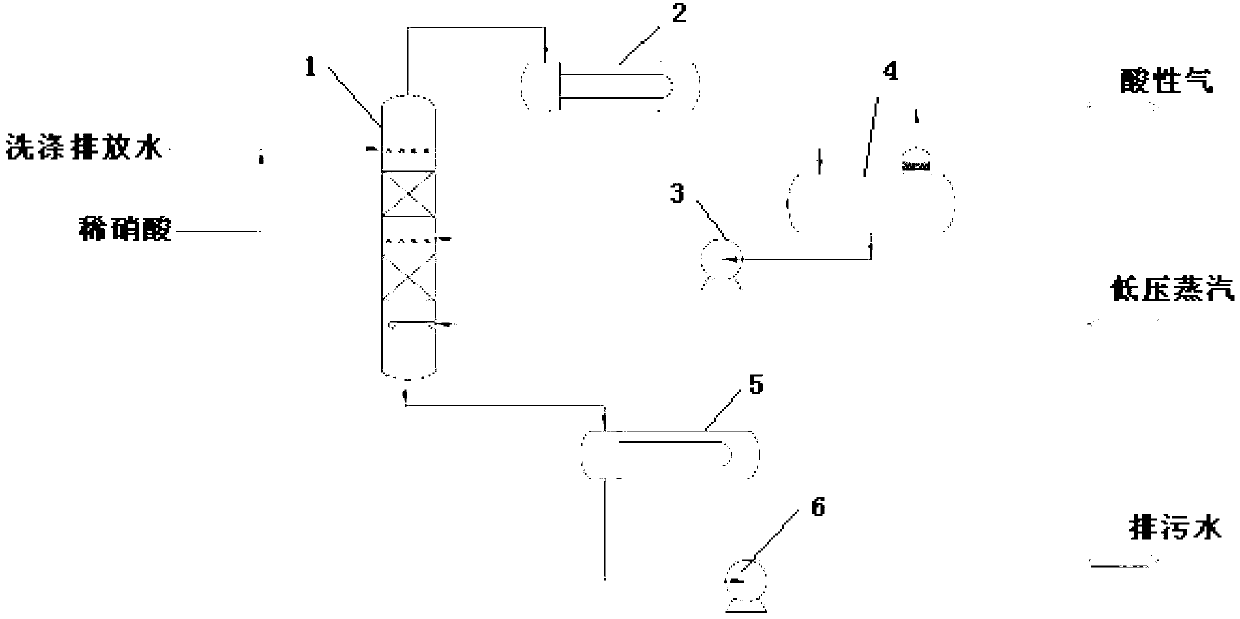

[0019] Embodiment: Taking coal gasification washing discharge water stripping as an example, refer to figure 1 , the gas washing water is neutralized with 20wt% dilute nitric acid to 6.5-7.0, then enters the stripping tower 1, contacts with the low-pressure steam countercurrently, and dissolves the H dissolved in the washing discharge water 2 S, CO 2 and NH 3 After the gas is stripped to the gas phase, the gas from the top of the stripping tower 1 is cooled to 80-100°C through the stripping gas cooler 2, and then the gas-liquid separation is carried out through the acid gas separation tank 4, and the separated liquid is passed through the stripping tower The reflux pump 3 returns to the stripper 1, and the separated acid gas is sent to the torch; the sewage discharged from the bottom and top of the stripper 1 is cooled to 40-50°C by the sewage cooler 5, and then pressurized by the sewage pump 6 Sent to sewage treatment plant. Wherein, the plate material of the stripping tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com