Treating method for in-depth dearomatization of diesel oil fraction

A processing method and technology for fractions, which are applied in the field of deep hydrodearomatization of diesel fractions to achieve the effects of enhanced gas-liquid passing capacity, increased contact area, and enhanced interphase transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

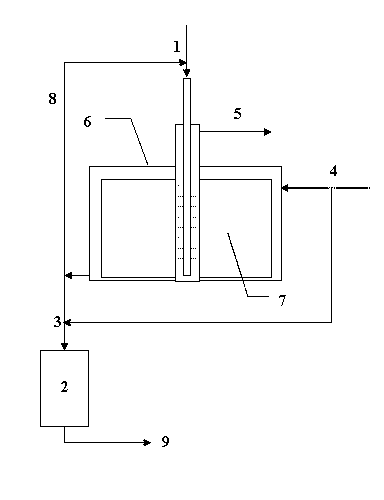

[0026] This example is an implementation of diesel hydrotreating, and the schematic diagram of the operation process refers to the attached figure 1 .

[0027] In this embodiment, the high-gravity reactor in the first reaction zone uses a non-precious metal catalyst, and the fixed-bed reactor in the second reaction zone uses a noble metal catalyst. The main properties of the catalyst are shown in Table 1, and the properties of the raw materials are shown in Table 2.

[0028] Table 1 Physicochemical properties of catalysts.

[0029] project non-precious metal catalyst noble metal catalyst Catalyst Active Components Mo, Ni, W Pt Active component content in terms of oxides, wt% 13 / 6 / 10 0.78 carrier Aluminum oxide USY molecular sieve shape clover bar diameter 3.1 2.0 Pore volume / mL·g -1 0.41 0.39 Specific surface area / m 2 g -1 235 143

[0030] Table 2 Main properties of raw oil.

[0031] Den...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com