Programmable polycrystalline silicon fuse device structure and realizing method of technology of programmable polycrystalline silicon fuse device structure

A polysilicon fuse and device structure technology, which is applied in the fields of electric solid device, semiconductor device, semiconductor/solid state device manufacturing, etc., can solve the problems of low integration of polysilicon fuse devices, inability to provide high programming voltage, and low integration, etc. Achieve obvious cost advantages, reduce costs, and improve the effect of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

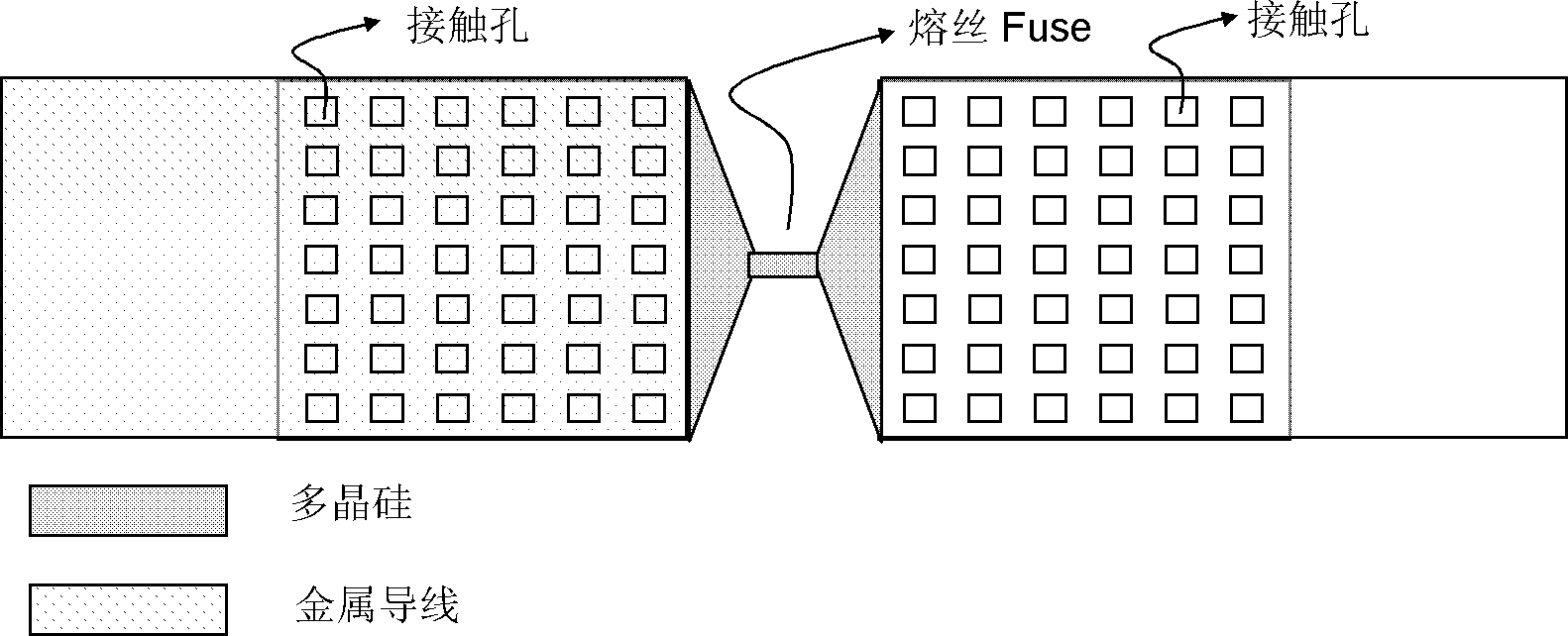

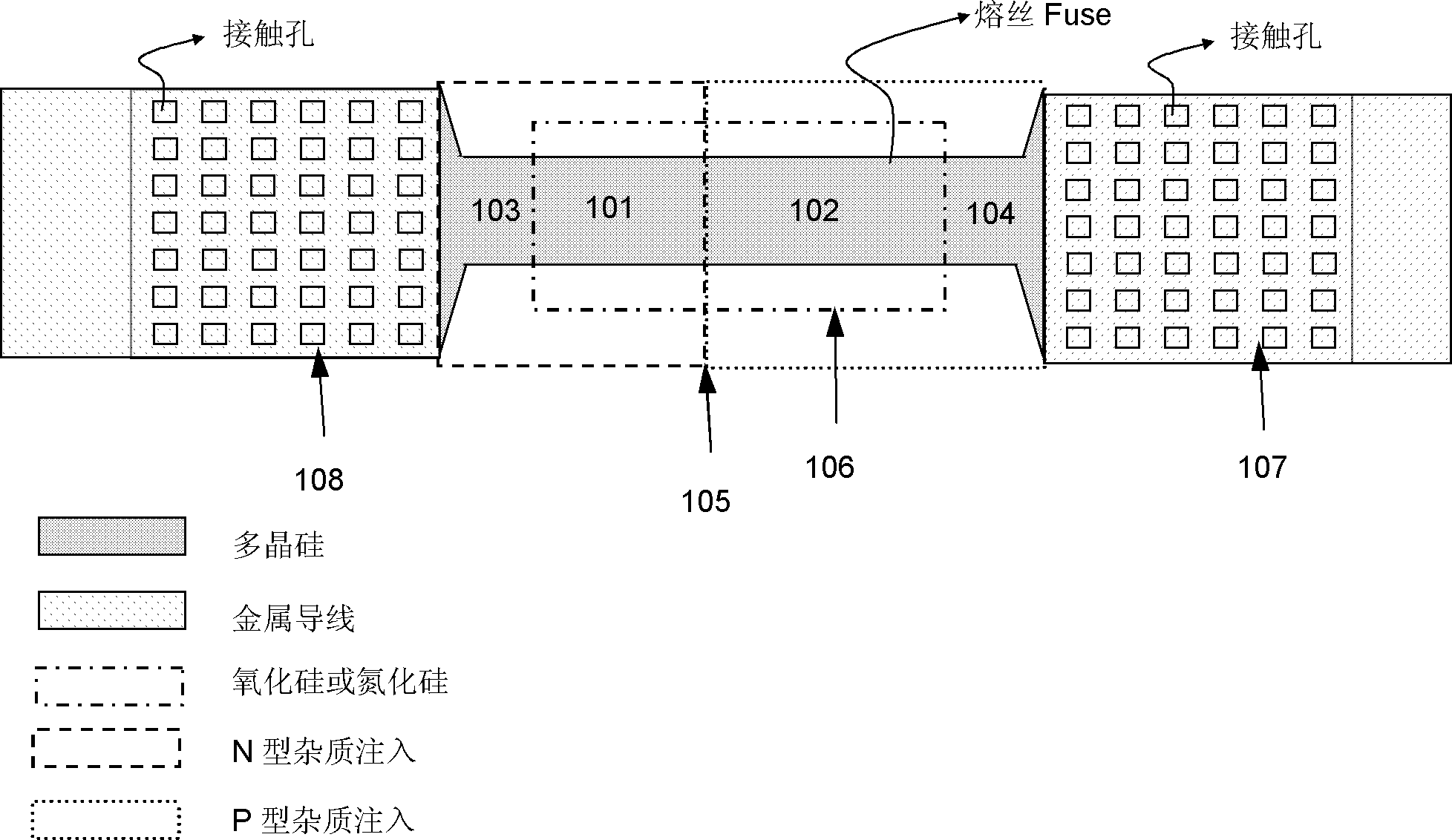

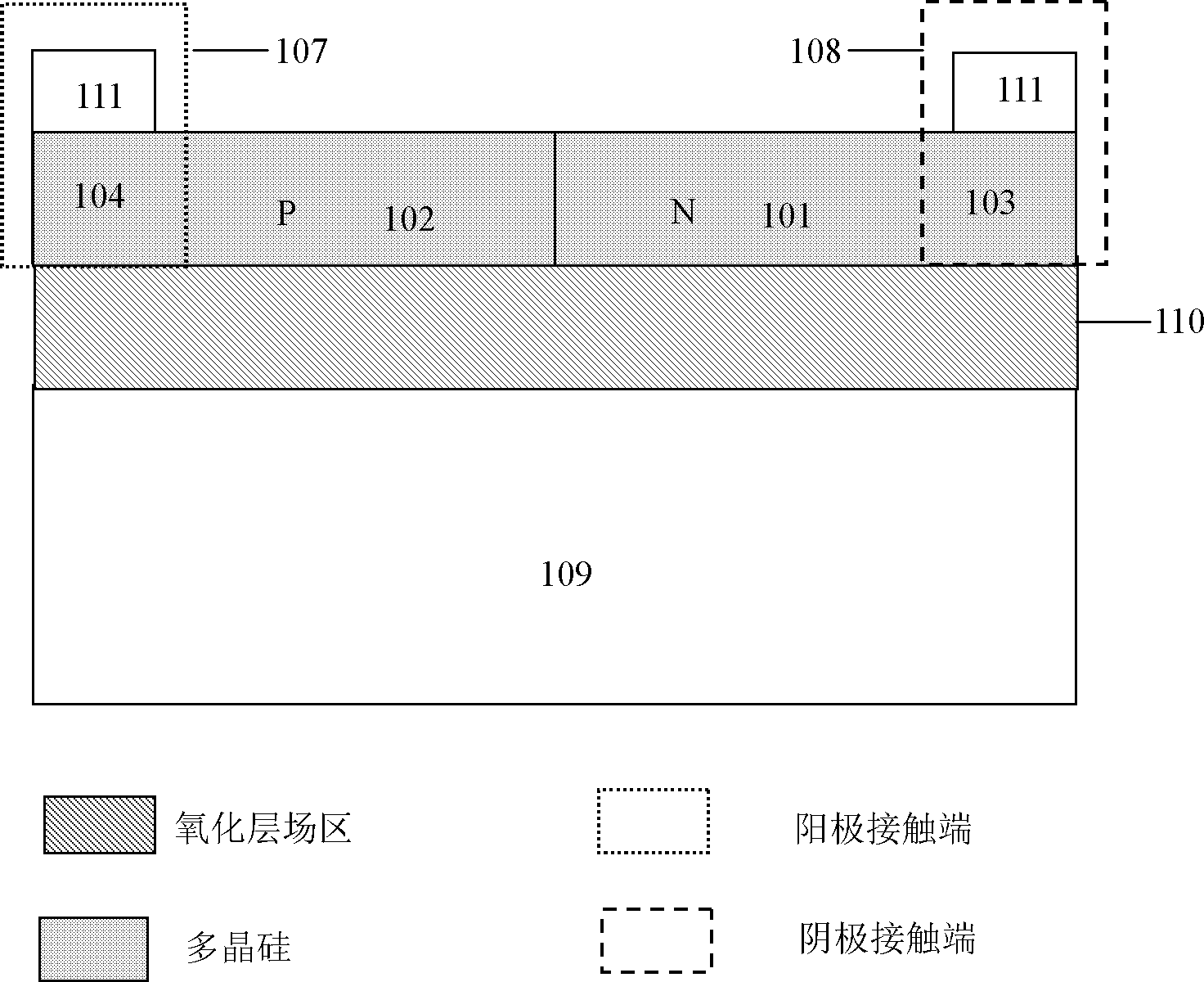

[0039] The programmable polysilicon fuse device structure of the present invention, as figure 2 shown, including:

[0040] N-type high-resistance polysilicon resistance 101 is composed of polysilicon and N-type impurity implantation, and its resistance is 2-3Kohm; there is no metal silicide 111 on the polysilicon, because silicon oxide or silicon nitride 106 is used on the polysilicon The process of forming the metal silicide 111 acts as a protective layer to prevent the formation of metal silicide on the polysilicon, so as to achieve the purpose of forming an N-type polysilicon resistor with a high resistance value;

[0041] P-type high-resistance polysilicon resistor 102 is composed of polysilicon and P-type impurity implantation, and its resistance is 2-3Kohm; there is no metal silicide 111 on the polysilicon, because silicon oxide or silicon nitride 106 is used on the polysilicon The process of forming the metal silicide 111 acts as a protective layer to prevent the form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com