Ionic crystal visible light catalyst based on dawson type polytungstate and preparation method thereof

A technology of ionic crystals and polytungstate, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the difficulty of catalyst separation and recovery and reduce photocatalytic reactions Quantum efficiency, low light quantum efficiency and other problems, to achieve the effect of enriching varieties and solving the difficulty of recycling and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

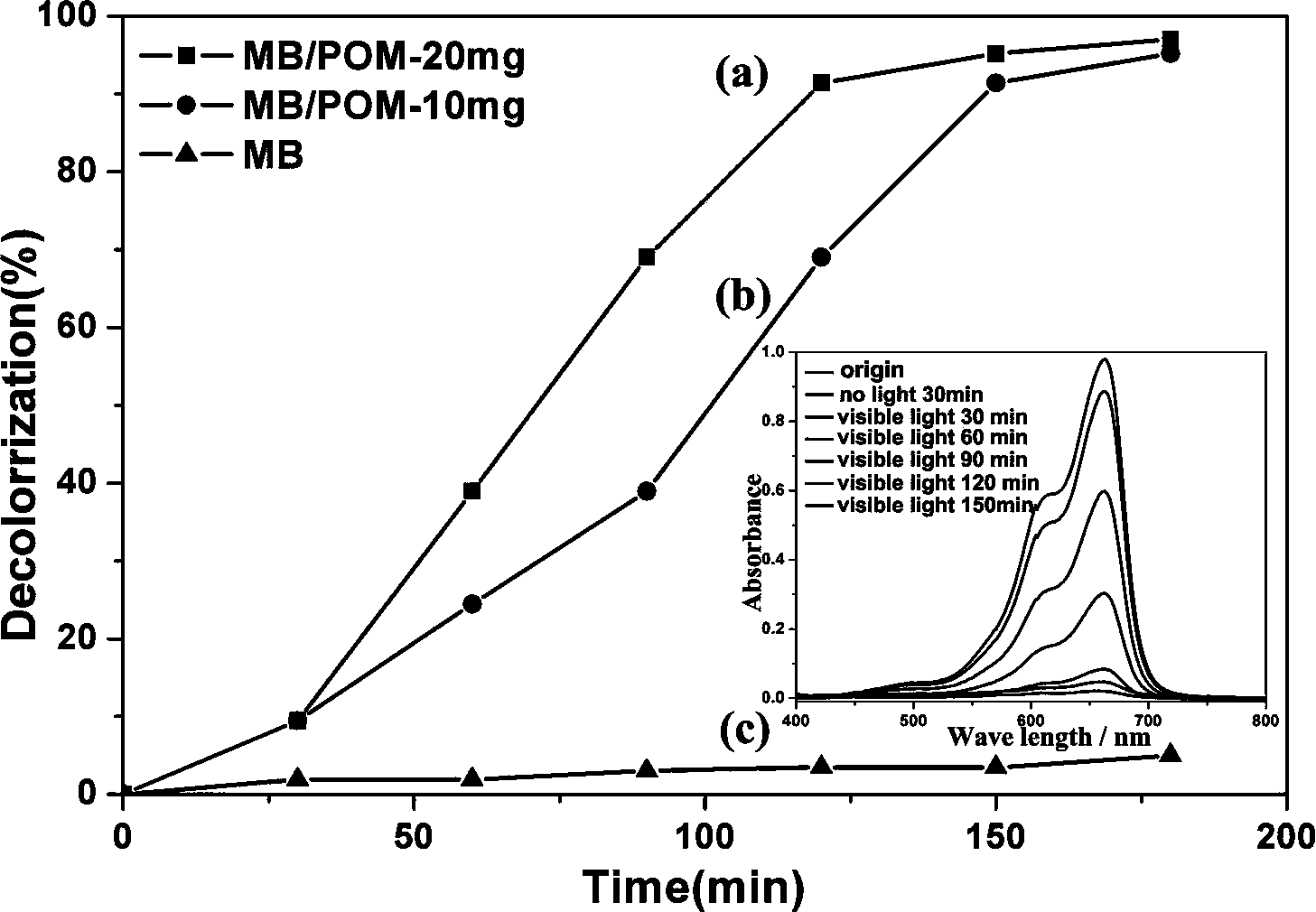

Image

Examples

Embodiment 1

[0019] Embodiment 1: get sample K 12 [α-H 2 P 2 W 12 o 48 ]·24H 2 O (0.667 g), NiCl 2 ·6H 2 O (0.333 g), Tris (0.167 g) and K 2 CO 3 (0.14 g) dissolved in 8 mL of water, with 4 mol L -1 Hydrochloric acid solution to adjust the pH value of the above solution to 6.4, stir at room temperature for 4 hours, add 0.6 mL of ethylenediamine, transfer the above solution to a 18 mL autoclave, react at 180 °C for 3 days, and cool naturally to After room temperature, dark blue blocky crystals can be obtained.

Embodiment 2

[0020] Embodiment 2: get sample K 12 [α-H 2 P 2 W 12 o 48 ]·24H 2 O (0.667 g), Ni (NO 3 ) 2 ·6H 2 O (0.406 g), Tris (0.167 g) and K 2 CO 3 (0.14 g) dissolved in 8 mL of water, with 4 mol L -1 Hydrochloric acid solution to adjust the pH value of the above solution to 6.5, stir at room temperature for 4 hours, add 0.6 mL of ethylenediamine, transfer the above solution to a 18 mL autoclave, react at 170 °C for 3 days, and cool naturally to After room temperature, dark blue blocky crystals can be obtained.

Embodiment 3

[0021] Embodiment 3: get sample K 12 [α-H 2 P 2 W 12 o 48 ]·24H 2 O (0.667 g), NiCl 2 ·6H 2 O (0.333 g), Tris (0.167 g) and K 2 CO 3 (0.14 g) dissolved in 8 mL of water, with 4 mol L -1 Hydrochloric acid solution to adjust the pH value of the above solution to 6.6, stir at room temperature for 4 hours, add 0.6 mL of ethylenediamine, transfer the above solution to a 18 mL autoclave, react at 160 °C for 3 days, and cool naturally to After room temperature, dark blue blocky crystals can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com