High-integration oxygen generator adsorption tower upper cover air inlet and nitrogen discharge system

A high-integration, adsorption tower technology, applied in the direction of oxygen preparation, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of reducing the sealing and reliability of the system, making it difficult to meet the use requirements, and affecting the sealing effect, etc., to achieve effective Conducive to miniaturization and high efficiency, simplified structure, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

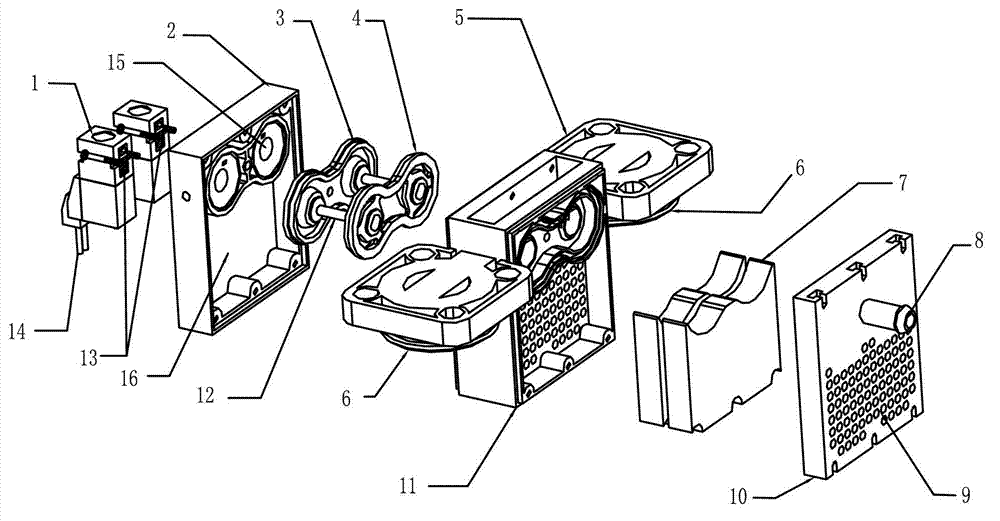

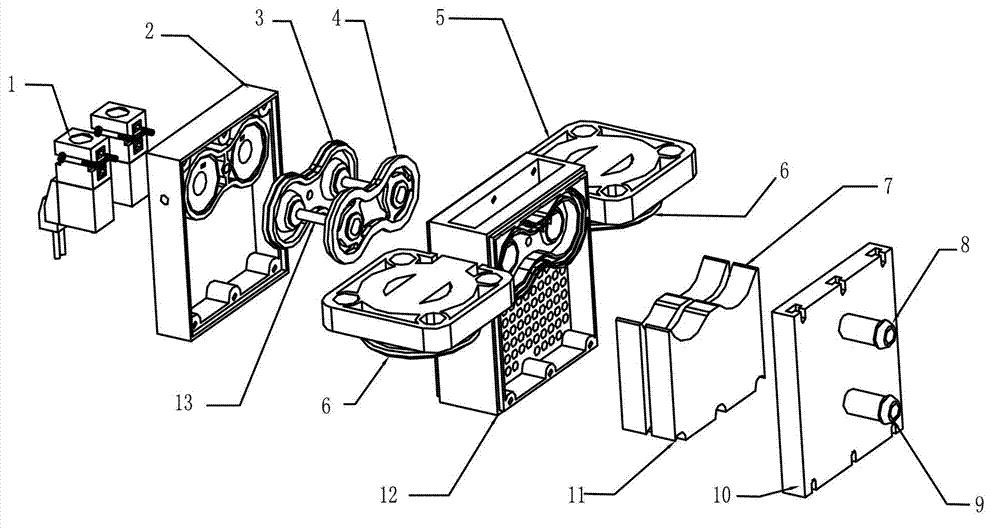

[0020] Below in conjunction with accompanying drawing, the present invention is further described: as figure 1 , 2 As shown in , the air intake and nitrogen exhaust system on the upper cover of the adsorption tower of the highly integrated oxygen generator is composed of the following components arranged in the horizontal order in the installed state: the air intake and nitrogen exhaust integrated compartment cover 10 at the intake end, the nitrogen exhaust Silencer cotton 7, adsorption tower upper cover 5, pneumatic valve core 12 with pneumatic valve seal ring 4 at the inlet end and valve end pneumatic valve seal ring 3 at both ends, air intake and nitrogen exhaust integrated bin cover at the valve end 2, electromagnetic valve 1. The upper cover of the adsorption tower and the nitrogen exhaust system are integrated, and the nitrogen exhaust, noise reduction, buffering, and gas path switching are integrated, thereby reducing pressure loss and noise, greatly simplifying the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com