Multi-stage flash distillation seawater desalination system of low-temperature multi-effect steamer vapor compression distillation

A technology of compressed steam distillation and multi-effect evaporation, which is applied in seawater treatment, water/sewage multi-stage treatment, general water supply conservation, etc., and can solve the problem of loss of fresh water output, decrease of ejector exergy efficiency, and decrease of system energy utilization rate, etc. problems, to achieve the effect of reducing the loss of available energy, improving energy utilization, and improving heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

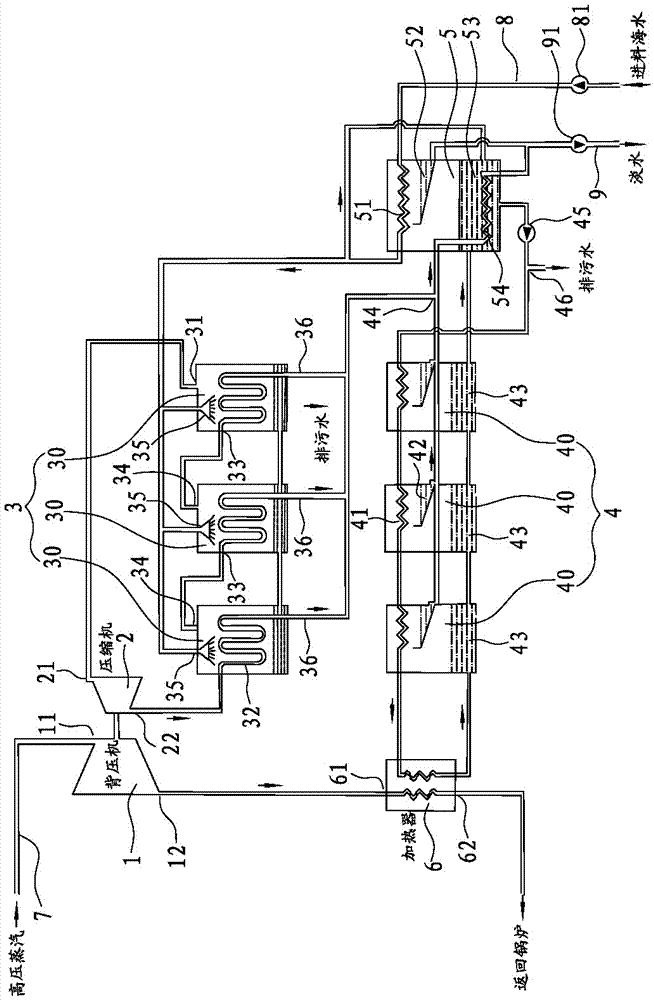

[0017] Such as figure 1 As shown, the present invention is a low-temperature multi-effect steam turbine pressure steam distillation-multistage flash seawater desalination system, which includes a back pressure machine 1, a compressor 2, a low-temperature multi-effect evaporator 3, a multi-stage flash evaporator 4, Final stage flash chamber 5, heater 6, heat source steam pipeline 7, feed seawater pipeline 8, fresh water outlet pipeline 9.

[0018] The steam inlet 11 of the back pressure machine 1 is connected to the heat source steam pipeline 7, the steam exhaust port 12 of the back pressure machine 1 is connected to the steam inlet 61 of the heater 6 through a pipeline, and the drain outlet 62 of the heater 6 is connected through a pipeline boiler.

[0019] The compressor 2 is coaxially connected to the back pressure machine 1, the inlet 21 of the compressor 2 is connected to the final-effect secondary steam outlet pipe 31 of the low-temperature multi-effect evaporator 3, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com