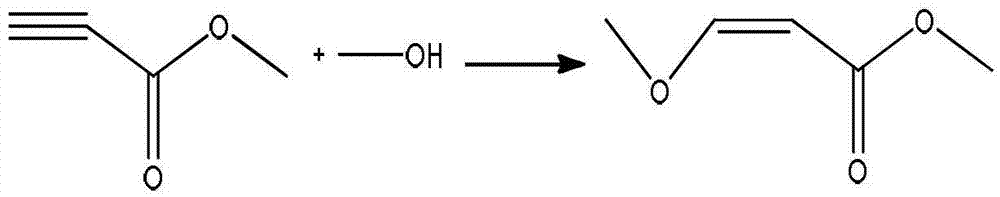

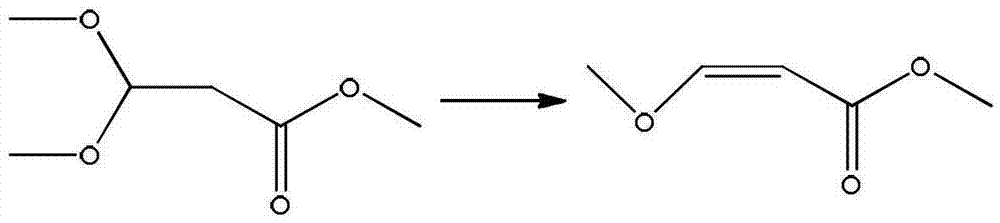

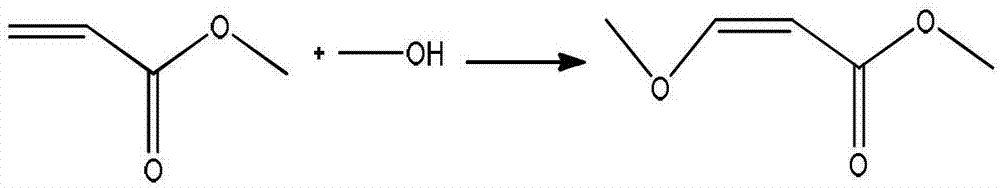

Preparation method of 3-methyl methoxyacrylate

A technology of methyl methoxy acrylate and methyl ethoxy propionate, which is applied in the field of preparation of methyl 3-methoxy acrylate, can solve problems such as difficult industrialization, expensive catalysts, and difficult recycling, and achieve cost low cost, simple method and ideal yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add 135g (833mmol) methyl 3-methoxy-3-ethoxypropionate, 800g methanol, and 2g potassium bisulfate to a 2000mL three-neck flask, heat and reflux for 24 hours after the addition, and change the reflux device to vacuum distillation device, and the solvent was removed under reduced pressure. The residue was heated to 140°C for 30 hours under the protection of nitrogen under normal pressure, and then distilled under reduced pressure to obtain 76.4 g (659 mmol) of methyl 3-methoxyacrylate with a purity of 97% (normalized by gas chromatography). The rate is 76.66%.

Embodiment 2

[0021] Add 135g (833mmol) methyl 3-methoxy-3-ethoxypropionate, 1200g methanol, and 2g sodium bisulfate to a 2000mL three-necked flask. Pressure distillation device, desolvent under reduced pressure; the residue was decompressed to 60mmHg, heated to 60°C for 10 hours, and then distilled under reduced pressure to obtain 72.2g (622mmol) of methyl 3-methoxyacrylate with a purity of 96% (gas phase Chromatographic normalization), the yield was 71.70%.

Embodiment 3

[0023] Add 100g (617mmol) methyl 3-methoxy-3-ethoxypropionate, 1500g methanol, and 5g sodium bisulfate to a 2000mL three-necked flask, heat and reflux for 48 hours after the addition, and change the reflux device to vacuum distillation equipment, and remove the solvent under reduced pressure; the residue was heated to 160°C under normal pressure for 5 hours of cracking reaction, and then distilled under reduced pressure to obtain 55.1g (475mmol) of methyl 3-methoxyacrylate with a purity of 95% (normalized by gas chromatography) , yield 73.10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com