Preparation method of high molecular material coolant

A technology of polymer materials and cold storage agents, which is applied in the direction of heat exchange materials, chemical instruments and methods, can solve the problems of long cold storage time, fast water absorption rate, complicated process, etc. The effect of fast and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

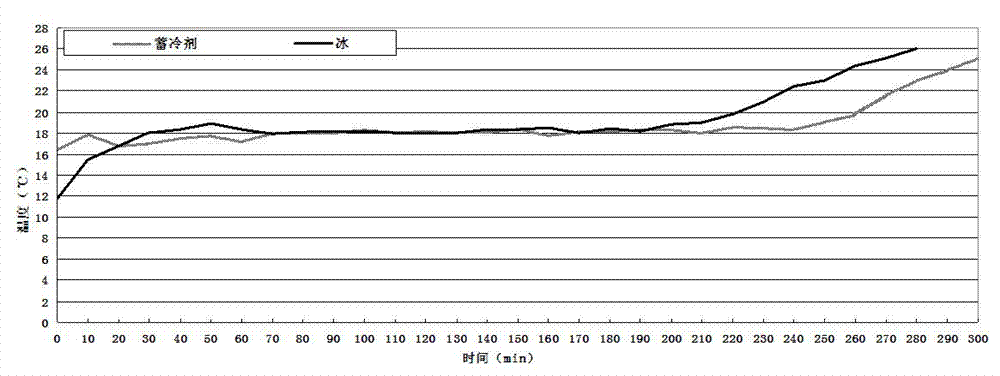

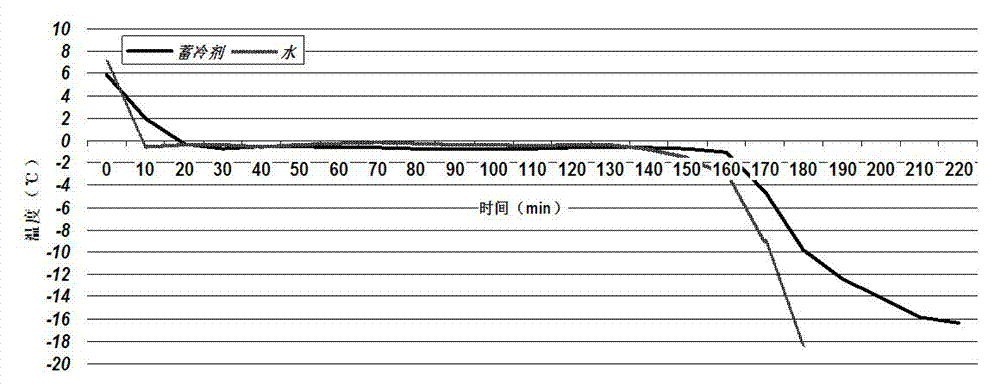

Image

Examples

Embodiment 1

[0024] 1) Put a beaker containing 36 grams of acrylic acid into ice water (it only needs to have ice cubes floating on the surface of the water), and add 20% sodium hydroxide solution to 36 grams of acrylic acid drop by drop, so that the neutralization degree is 80 % sodium acrylate solution, and stirred to allow it to cool to room temperature;

[0025] 2) Take 0.0252 grams of N-N'methylene bisacrylamide crosslinking agent and 0.054 grams of potassium persulfate initiator and add it to 10 grams of tap water, stir well to dissolve it completely, and then add it to acrylic acid with a neutralization degree of 80%. In the sodium solution, fully stir and mix evenly to obtain a mixed solution;

[0026] 3) Add 18 grams of tap water to the mixed solution, and adjust the mass percentage concentration of acrylic acid monomer in the mixed solution to 25%;

[0027] 4) Put the mixed solution of acrylic acid monomer mass percentage 25% into an oven at a temperature of 90°C, react for 4 ho...

Embodiment 2

[0037] 1) Put a beaker containing 36 grams of acrylic acid into ice water (it only needs to have ice cubes floating on the surface of the water), add 20% sodium hydroxide solution to 36 grams of acrylic acid drop by drop, and configure the neutralization degree to be 75 % sodium acrylate solution, and stirred to allow it to cool to room temperature;

[0038] 2) Take 0.0432 grams of N-N'methylene bisacrylamide crosslinking agent and 0.054 grams of potassium persulfate initiator and add it to 10 grams of tap water, stir well to dissolve it completely, and then add it to sodium acrylate with a neutralization degree of 75%. solution, fully stirred and mixed evenly to obtain a mixed solution;

[0039] 3) Add 23 grams of water into the mixed solution, and adjust the mass percentage concentration of acrylic acid monomer in the mixed solution to 25%;

[0040] 4) Put the mixed solution of acrylic acid monomer mass percentage concentration of 25% into an oven at a temperature of 80°C, ...

Embodiment 3

[0048] 1) Put a beaker containing 36 grams of acrylic acid into ice water (it only needs to have ice cubes floating on the surface of the water), and add 20% sodium hydroxide solution to the acrylic acid drop by drop to form a neutralization degree of 70%. Sodium acrylate solution, and let it cool to room temperature with stirring;

[0049]2) Add 0.0432 grams of N-N'methylenebisacrylamide crosslinking agent and 0.054 grams of potassium persulfate initiator to 5 grams of tap water, stir thoroughly to dissolve it completely, and then add it to acrylic acid with a neutralization degree of 70%. In the sodium solution, fully stir and mix evenly to obtain a mixed solution;

[0050] 3) Add 3 grams of tap water into the mixed solution, and adjust the mass percentage concentration of acrylic acid monomer in the mixed solution to 30%;

[0051] 4) Put the mixed solution of acrylic acid monomer with a mass percentage concentration of 30% in an oven at a temperature of 90°C, react for 4 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com