Full-glass solar vacuum heat-collecting tube and preparation method thereof

A vacuum heat collector tube and solar energy technology, which is applied to solar thermal power generation, solar thermal devices, vacuum evaporation coating, etc., can solve the problem that the solar spectrum absorption film layer does not have oxidation resistance, the production process of solar heat collector tube is complicated, and the process time is increased. and processing costs, to achieve the effect of reducing time urgency, improving exhaust effect and production efficiency, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

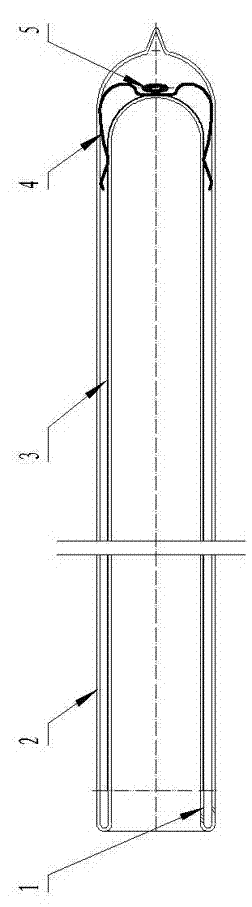

[0050] Embodiment 1, with reference to the accompanying drawings, a kind of all-glass solar energy vacuum heat collection tube, the heat collection tube includes a cover tube 2, an inner tube 1 and a bracket assembly, the inner tube 1 is arranged in the cover tube 2, the outer end of the inner tube 1 and the cover The tube 2 is fixedly connected; the inner end of the inner tube 1 is fixed in the cover tube 2 through the bracket assembly; the outer surface of the inner tube 1 is provided with an anti-oxidation selective absorption coating 3, and the coating is sequentially formed from the base material to the outside A diffusion bonding layer, an infrared reflection layer, a diffusion barrier layer, an absorption layer, a suede texture layer and an anti-reflection layer are laminated, and the diffusion bonding layer, the diffusion barrier layer, and the suede texture layer are selected from Fe, FeM alloys , one or more of Ti, TiM alloy, Cr, CrM alloy, Ni, NiM alloy, Al, AlM allo...

Embodiment 2

[0051] Embodiment 2, in the all-glass solar vacuum heat collecting tube described in Embodiment 1, the support assembly includes a stainless steel tube clamp 4, the stainless steel tube clamp 4 is connected with a getter support 5, and the getter support 5 is provided with a non-evaporable Getter, there may be no getter on the getter bracket 5 .

Embodiment 3

[0052] Example 3: In the all-glass solar vacuum heat collection tube described in Example 1, the thicknesses of the diffusion bonding layer, the diffusion barrier layer, and the suede texture layer are respectively 2-5 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com