Nondestructive testing method for optical glass polishing sub-surface damages

A subsurface damage, optical glass technology, applied in the direction of material analysis, measuring device, scientific instrument, etc. by optical means, to achieve the effect of flexible and controllable detection area, high detection efficiency, and fast detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

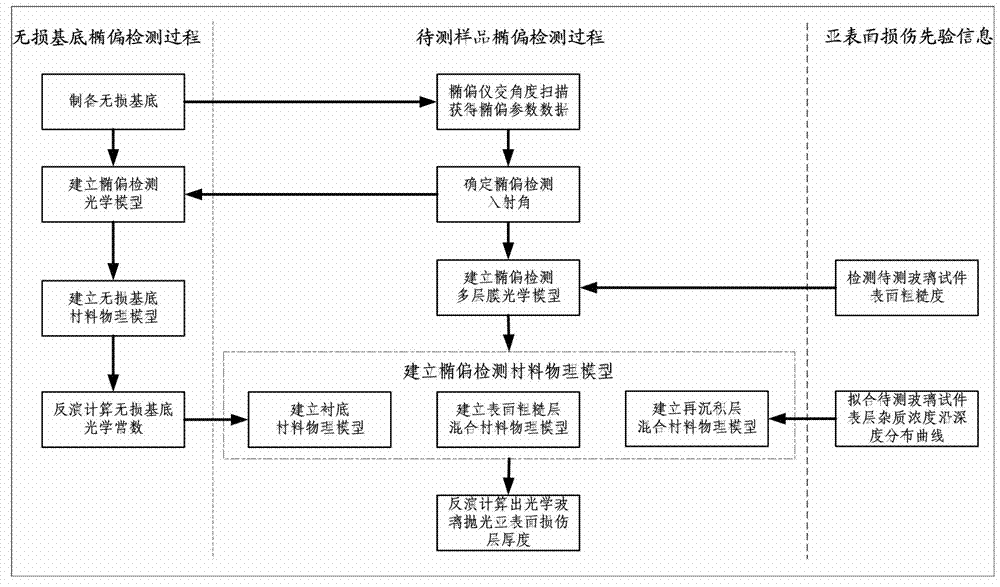

[0038] a kind of like figure 1 The nondestructive detection method of the optical glass polishing subsurface damage of the present invention shown, comprises the following steps:

[0039] (1) Preparation of non-destructive substrate: select Φ20mm×5mm quartz glass sample traditionally polished by cerium oxide as the glass sample to be tested; Liquid viscosity 350×10 -3 Pa s, using PF-1-1 cerium oxide polishing powder, current intensity 5A, polishing wheel speed 60r / min, flow rate 2L / min, magnetorheological polishing time 12h, the surface roughness after magnetorheological polishing was measured by atomic force microscope The Ra value is 0.359373nm; at 12°C, use 5% hydrofluoric acid to etch the sample after magnetorheological polishing for 3 minutes, and the etching depth is 59.6nm, which can effectively remove the subsurface mechanical damage and polishing redeposited substances left by traditional polishing. Get a lossless base;

[0040] (2) Determine the incident angle of ...

Embodiment 2

[0051] a kind of like figure 1 The nondestructive detection method of the optical glass polishing subsurface damage of the present invention shown, comprises the following steps:

[0052] (1) Preparation of non-destructive substrate: choose Φ20mm×5mm size and undergo rough magnetorheological polishing (using x-y scanning method, magnetorheological fluid viscosity 350×10 -3 Pa s, using PF-1-1 cerium oxide polishing powder, current intensity 6A, polishing wheel speed 80r / min, flow rate 31 / min, polishing time 2h) quartz glass sample as the glass sample to be tested; first use magnetorheological Polishing process The glass sample to be tested is polished, and the specific polishing parameters are the same as in Example 1. The surface roughness Ra value measured by an atomic force microscope is 0.370702nm; Sample 3min, etching depth 71nm, effectively remove subsurface mechanical damage and polishing re-deposited substances left by magnetorheological rough polishing, and obtain a n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com