Quartz vibration beam accelerometer and manufacture method thereof

A technology of an accelerometer and a manufacturing method, which are applied in the directions of measuring acceleration, velocity/acceleration/impact measurement, and manufacturing microstructure devices, etc., can solve the problems of low accelerometer accuracy, unsatisfactory assembly effect, and high production cost, and achieve machining accuracy. High, high assembly precision, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

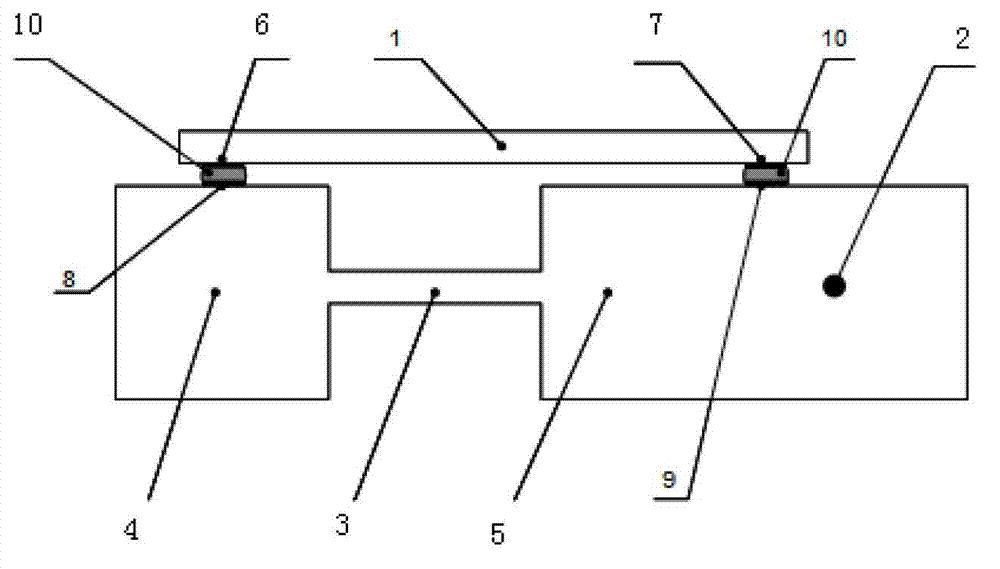

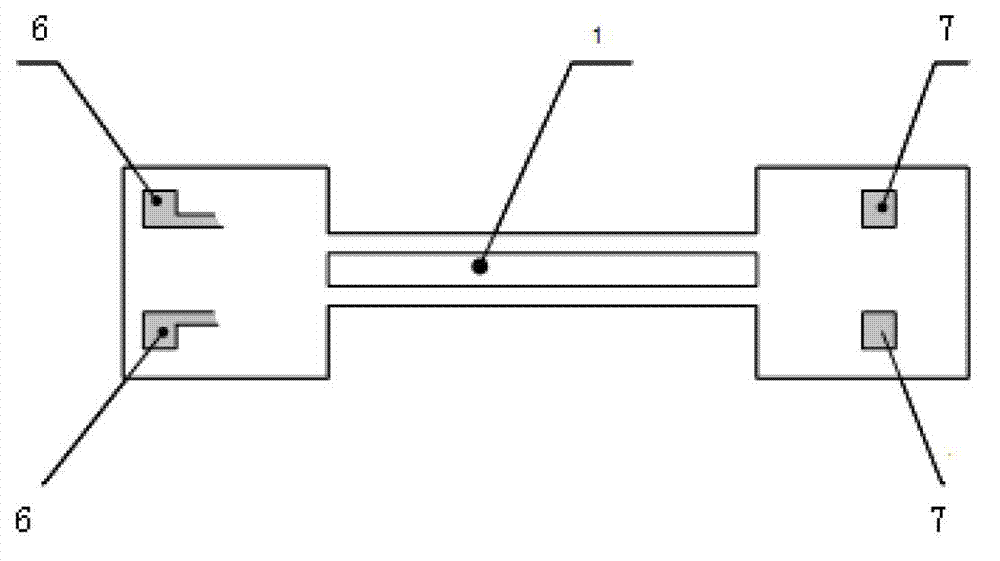

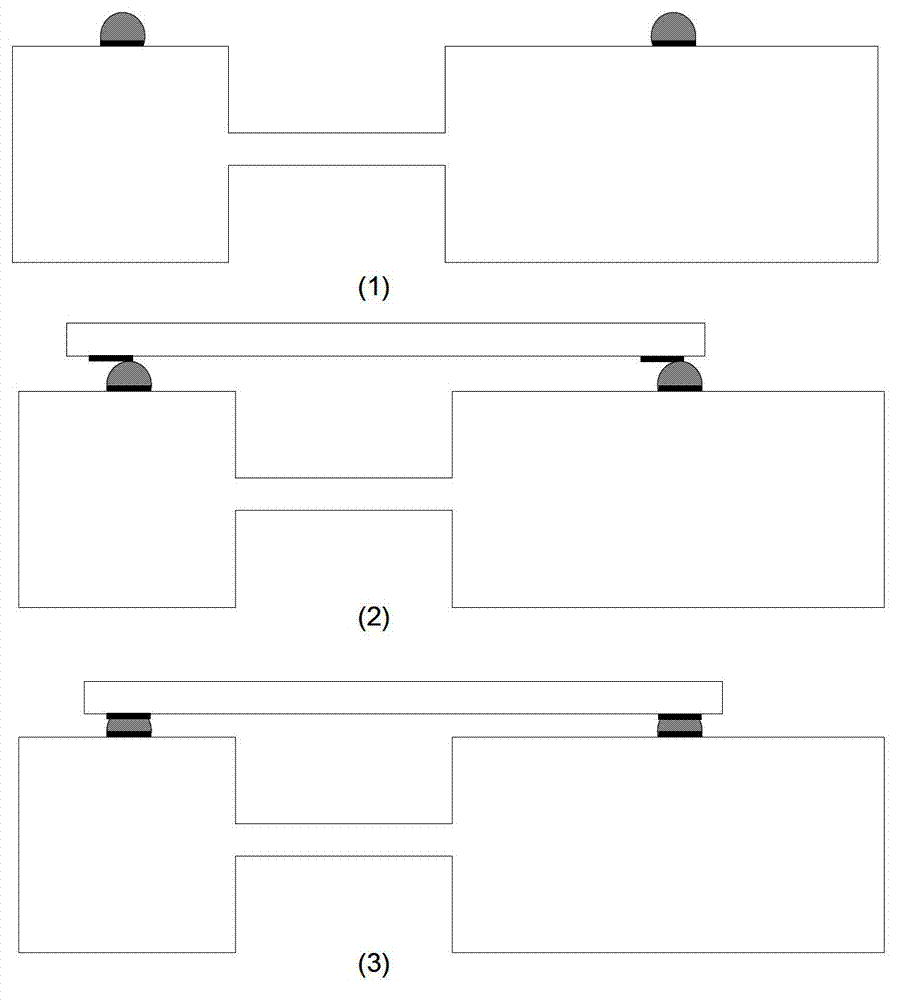

[0015] Such as figure 1 As shown, the quartz vibrating beam accelerometer of the present invention is composed of a quartz vibrating beam 1 and a mass-flexible structure 2, wherein the mass-flexible structure 2 is an integrated structure composed of a base 4, a flexible hinge 3 and a mass 5 , the quartz vibrating beam 1 and the mass-flexible structure 2 are assembled via bonding of a metal alloy material 10 . The quartz vibrating beam and the mass-flexible structure are made of quartz wafers of different thicknesses respectively, and the vibrating beam is made of a small-thickness quartz chip to improve the force-frequency effect of the vibrating beam; the mass-flexible structure is made of a thick quartz chip, To obtain a large enough mass, generate a large inertial force, and then provide a large enough axial force to the vibration beam structure through the deformation of the flexible structure; the thickness of the mass block is the same as the thickness of the base, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com