Composite battery diaphragm

A composite battery and diaphragm technology, which is applied to battery components, circuits, electrical components, etc., can solve the problem that the battery diaphragm is difficult to meet the safety requirements of lithium-ion batteries, and achieve low production process cost, low price, excellent breathability The effect of sex and heat shrinkability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

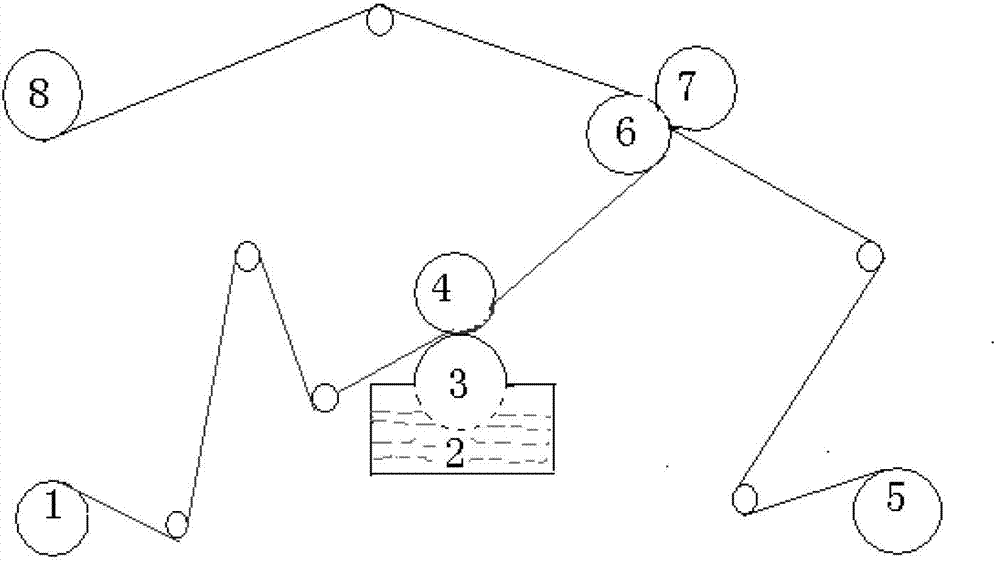

[0030] The preparation process of this example is as follows figure 1 As shown, weigh 200 grams of polytetrafluoroethylene and 2 kilograms of N-methylpyrrolidone, abbreviated as NMP, put them into the glue pool 2, stir and fully dissolve, and take a roll of polyethylene porous with a thickness of 10 μm and a porosity of 42%. The film is fixed at unwinding 1, and a roll of polypropylene non-woven fabric with a gram weight of 15 g / m2 is placed at unwinding 5, and the polyethylene porous film and non-woven fabric are both unwound at a speed of 15 cm / s. Roll, wherein, the polyethylene porous membrane is glued on the gluing pattern roller 3 with reticular lines, the depth of the mesh groove of the gluing pattern roller 3 is 2 μm, and the excess glue is scraped off by the squeegee roller 4, and the gluing The final polyethylene porous film and non-woven fabric are bonded and compacted at the press roller 6 and press roller 7, and finally the obtained compacted polyethylene porous fi...

Embodiment 2

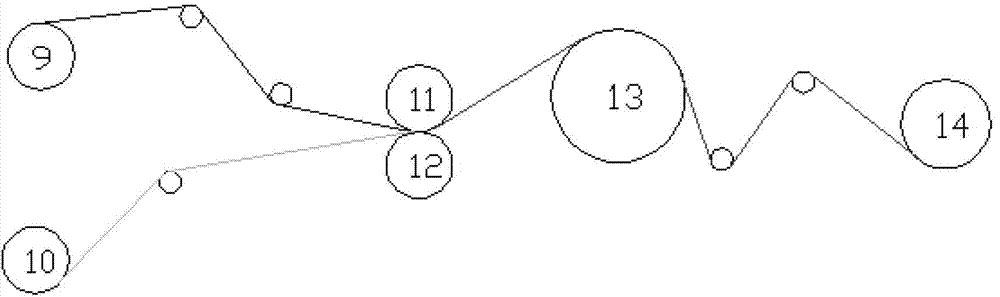

[0032] The preparation process of this example is as follows figure 2 As shown, a roll of thickness is 12 μ m, porosity is 42%, the polyethylene microporous membrane that width is 250 mm and a roll of grammage is 12 g / m2 polypropylene non-woven fabric are respectively fixed on unwinding 9 and 10 locations, and unwind at a speed of 3 cm / s. On the way, the polyethylene microporous film is pretreated at a temperature of 100°C and passes through a mesh pattern roller 12 with heat-conducting oil. The roller temperature is 150°C and the Shore The rubber pressure roller 11 with a hardness of 55 degrees moves down to press the patterned roller. The pressure is set at 0.5MPa. After compounding, it is shaped by the shaping roller 13, and the temperature is set at 125°C. Finally, it is wound by the winding roller 14 to obtain heat resistance. Lithium-ion battery porous membrane, that is, the composite battery separator in this example.

Embodiment 3

[0034] Composite battery diaphragm is prepared according to the method of Example 2, the difference is that the thickness of the polyethylene microporous membrane used is 16 μm, and the porosity is 47%; Ethylene glycol diformate non-woven fabric; and, the unwinding speed of the polyethylene microporous film and the non-woven fabric is 5 cm / s, the temperature of the patterned roller is 210 ° C, and the Shore hardness of the rubber pressing roller is 45 degrees, The pressure is 1.5MPa, and the temperature of the sizing roller is set at 110°C. All the other are identical with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com