Manufacturing method of computer outer shell

A technology for computer shells and manufacturing methods, applied in chemical instruments and methods, synthetic resin layered products, lamination devices, etc., can solve the problems of low yield rate, increased damage and oxidation, and easy corrosion of magnesium alloys for computer shells. Achieve short processing time, reduce surface pores, and reduce surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

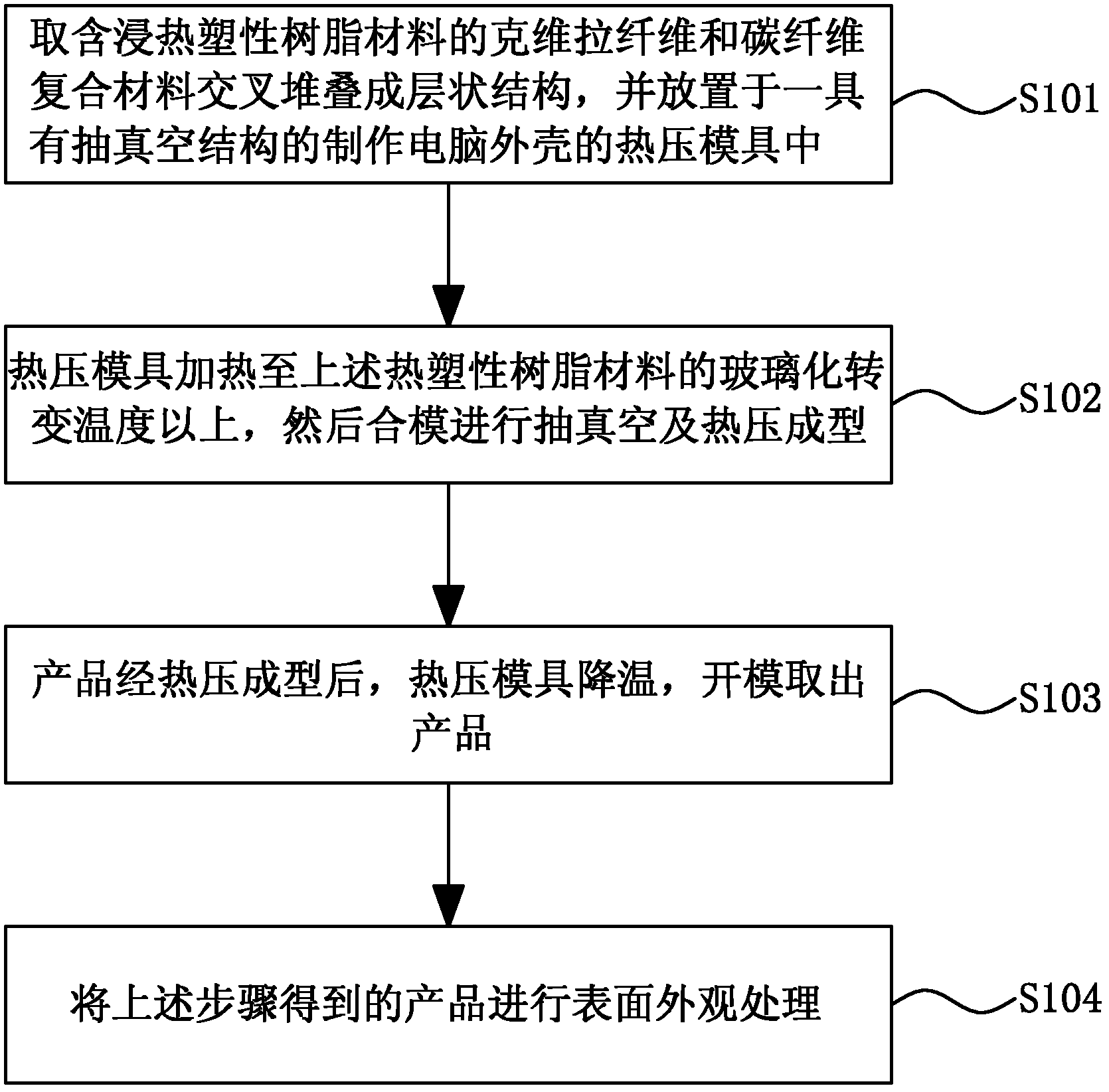

[0024] Step 101: Take kevlar fibers impregnated with thermoplastic PA and carbon fiber composite materials to form a layered structure, and place them in a heat-pressing mold with a vacuum structure for making a 10-inch notebook computer casing;

[0025] Step 103: heating the hot pressing mold to 200°C, then closing the molds for vacuuming and hot pressing;

[0026] Step 104: After the product is hot-pressed, the temperature of the hot-pressing mold is lowered to 50°C, and the mold is opened to take out the product;

[0027] Step 105: After the surface appearance treatment of the product obtained in the above steps, such as grinding, spray painting, thermal transfer printing, water transfer printing or leather application, a strong and thin product with high rigidity, toughness and super shock absorption effect can be obtained. military-spec laptop case.

Embodiment 2

[0029] Step 201: taking kevlar fibers impregnated with thermoplastic PA and carbon fiber composite materials cross-stacked to form a layered structure, and covering the uppermost layer and the lowermost layer respectively with a PA film with a thickness of 0.1mm made into the design shape of the notebook shell, Placed in a hot pressing mold with a vacuum structure to make a 15-inch notebook computer casing;

[0030] Step 202: heating the hot pressing mold to 280°C, then closing the molds for vacuuming and hot pressing;

[0031] Step 203: After the product is hot-pressed, the temperature of the hot-pressing mold is lowered to 45°C, and the mold is opened to take out the product;

[0032] Step 204: After the surface appearance treatment of the product obtained in the above steps, such as grinding, spray painting, thermal transfer printing, water transfer printing or leather application, a strong and thin product with high rigidity, toughness and super shock absorption effect can...

Embodiment 3

[0034] Step 301: Take kevlar fibers impregnated with thermoplastic ABS and carbon fiber composite materials and cross-stack them to form a layered structure, and cover the uppermost layer and the lowermost layer respectively with an ABS / PMMA with a thickness of 0.3 mm made into the design shape of the notebook shell The film is placed in a hot pressing mold with a vacuum structure for making a 15-inch notebook computer casing;

[0035] Step 302: heating the hot pressing mold to 110°C, and then closing the molds for vacuuming and hot pressing;

[0036] Step 303: After the product is hot-pressed, the temperature of the hot-pressing mold is lowered to 50°C, and the mold is opened to take out the product;

[0037] Step 304: After the surface appearance treatment of the product obtained in the above steps, such as grinding, spray painting, heat transfer printing, water transfer printing or leather application, a strong and thin product with high rigidity, toughness and super shock ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com