Synthetic method of molecular sieve ZSM-5 (zeolite socony mobil-5) with heteroatom-containing frame

A ZSM-5, synthesis method technology, applied in the directions of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of complex synthesis of molecular sieves and low yield, etc. Good technical effect, easy to synthesize effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

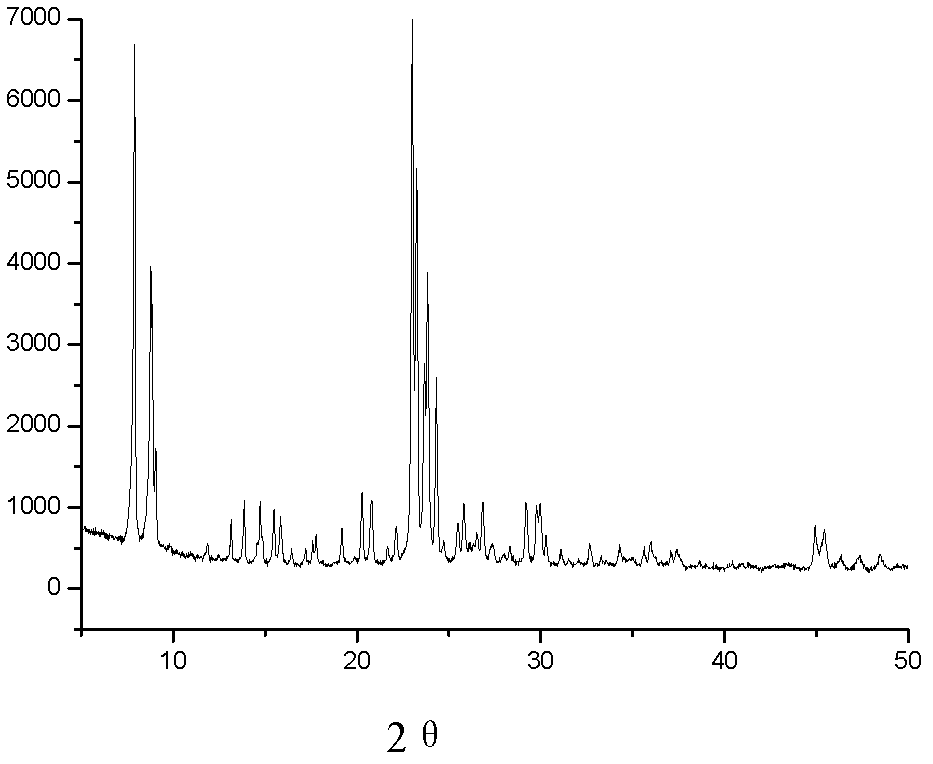

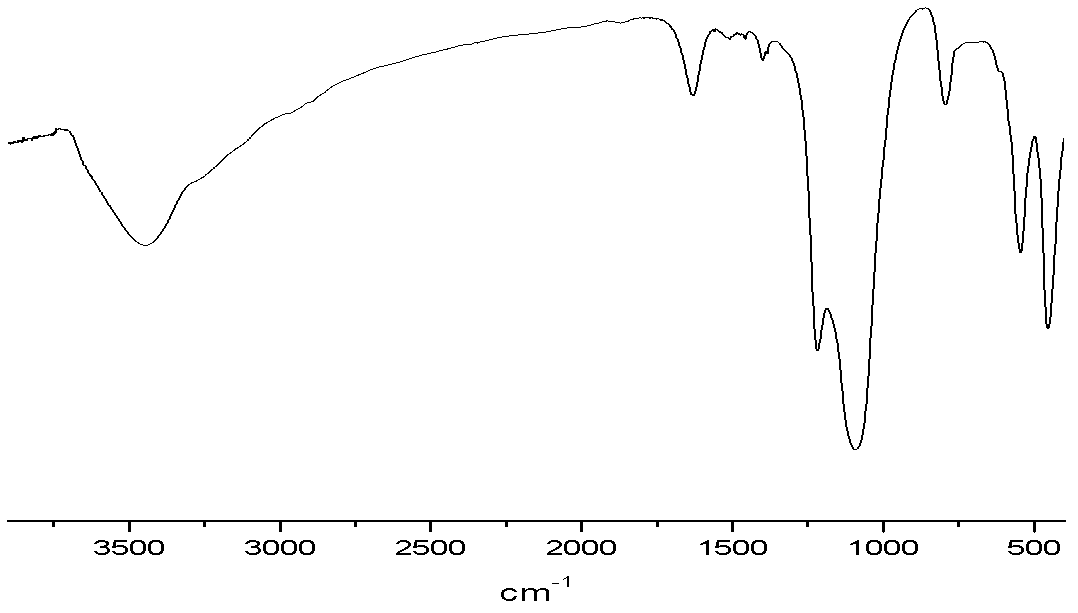

[0021] Dissolve 9.0 g of aluminum sulfate octadecahydrate, 2.0 g of ferric sulfate, 20.0 g of water, and 1.0 g of sulfuric acid to form a solution. 120.0 grams of water glass (containing 21% silicon dioxide, 6.5%) will be weighed. The above two materials are strongly stirred to form a gel. Dry at 50° C. for 150 hours to obtain a solid dry glue. Take 10.0 g of dry glue and put it into the upper part of the crystallization kettle, add 500.0 g of water to the lower part of the crystallization kettle, and add 1.5 g of tetrapropylammonium bromide to the top of the dry glue. Crystallize under airtight conditions at 140°C for 90 hours to obtain Fe-AlZSM-5 molecular sieves. For XRD and IR characterization results see figure 1 , figure 2 .

Embodiment 2

[0023] Dissolve 6.0 g of aluminum sulfate octadecahydrate, 1.0 g of ammonium vanadate, and 20.0 g of water to form a solution. Mix 50.0 g of silica sol (containing 40% silicon dioxide) and 5.0 g of sodium hydroxide. The above two materials were vigorously stirred to form a gel, and the pH of the mixture was 9. Spin-dry at 200° C. for 0.5 hour to obtain a solid dried gel. Take 20.0 g of dry glue and put it into the upper part of the crystallization kettle, add 10.0 grams of water in the crystallization kettle, and add 4.0 grams of tetrapropylammonium hydroxide aqueous solution (containing 30%) on the dry glue. Crystallize at 150°C for 60 hours under airtight conditions. Obtained V-AlZSM-5 molecular sieve.

Embodiment 3

[0025] Dissolve 0.6 g of germanium nitrate, 20.0 g of water, and 0.5 g of nitric acid to prepare a solution. 120.0 g of silica sol (containing 40% silicon dioxide by weight concentration) and 7.0 g of potassium hydroxide will be weighed. The above two materials are strongly stirred to form a gel. The pH value of the mixture was 9, and it was dried at 50°C for 2 hours and then at 120°C for 6 hours to obtain a solid dry gel. Take 20.0 g of dry glue and put it into the upper part of the crystallization kettle, add 600.0 grams of water in the crystallization kettle, and add 2.0 grams of tetrapropylammonium hydroxide aqueous solution (containing 30%) on the dry glue. Crystallize at 150°C for 90 hours under airtight conditions. Ge-ZSM-5 molecular sieves were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com