Method for disproportionation and transalkylation of toluene heavy aromatics

A technology of transalkylation and toluene, which is applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve the problems of high loss rate of aromatic rings and high hydrogen consumption in reactions, and achieve good stability, good technical effects, and reduced Aromatic ring loss rate and effect of reaction hydrogen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

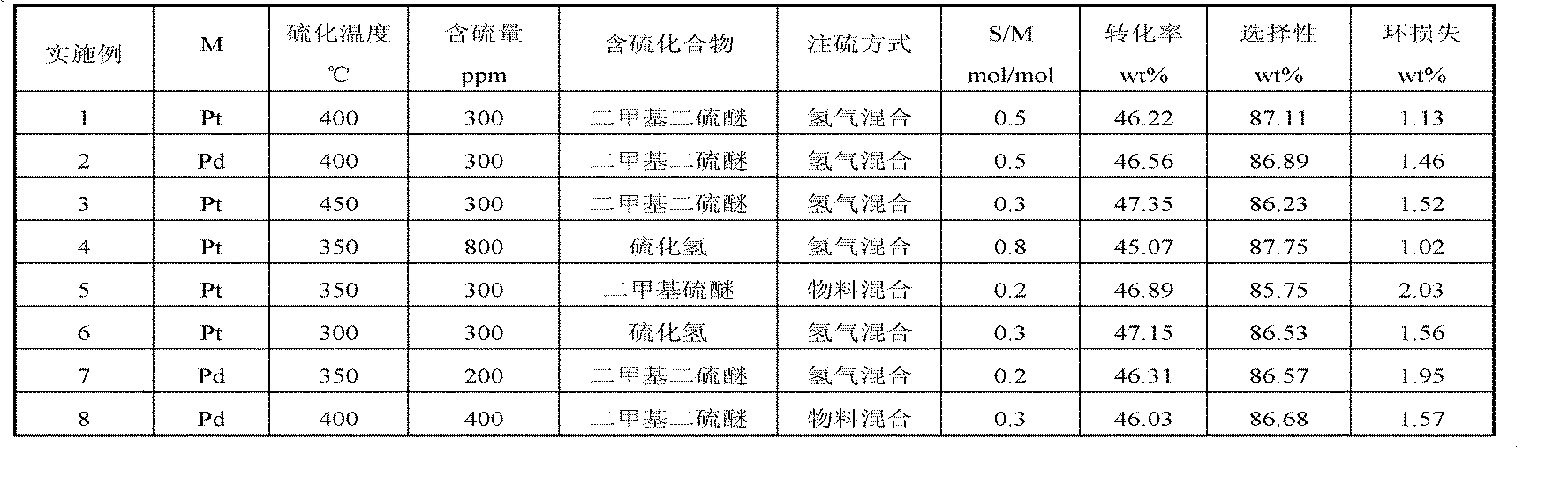

Examples

Embodiment 1

[0017] Na 2 O content less than 0.1% (weight), SiO 2 / Al 2 o 3 66.7 grams of ammonium type beta zeolite with a molecular ratio of 30 and Na 2 γ-Al with O content less than 0.1% by weight 2 o 3 ·H 2 O 57.1 grams are uniformly mixed, then added a certain amount of dilute nitric acid and Tian Qing powder, kneaded evenly, extruded into strips, roasted to make a carrier, and placed in an impregnation container after dicing. The carrier was impregnated with a certain amount of chloroplatinic acid solution, dried at 120°C for 4 hours, calcined at 500°C for 3 hours, and then reduced at 400°C to obtain catalyst A (0.1 wt% Pt / β).

[0018] Take 100ml of catalyst A, place it in a tubular reactor, feed 500ml / min of hydrogen, gasify a certain amount of dimethyl disulfide and mix it with hydrogen. The sulfur content in the mixed gas is 300ppm. Pass the mixed gas once through the catalyst bed, and carry out sulfidation at 400°C, so that the molar ratio of sulfur content to metal conten...

Embodiment 2

[0020] Na 2 O content less than 0.1% (weight), SiO 2 / Al 2 o 3 66.7 grams of ammonium mordenite with a molecular ratio of 30 and Na 2 γ-Al with O content less than 0.1% by weight 2 o 3 ·H 2 O 57.1 grams are uniformly mixed, then added a certain amount of dilute nitric acid and Tian Qing powder, kneaded evenly, extruded into strips, roasted to make a carrier, and placed in an impregnation container after dicing. The carrier was impregnated with a certain amount of palladium chloride solution, dried at 120°C for 4 hours, calcined at 500°C for 3 hours, and then reduced at 400°C to prepare catalyst B (0.2wt% Pd / mordenite). Catalyst sulfidation conditions and performance evaluation conditions are as in Example 1.

Embodiment 3

[0022] Take 100ml of catalyst A, place it in a tubular reactor, feed 500ml / min of hydrogen, gasify a certain amount of dimethyl disulfide and mix it with hydrogen. The sulfur content in the mixed gas is 300ppm. Pass the mixed gas once through the catalyst bed, and carry out sulfidation at 450°C, so that the molar ratio of sulfur content to metal content on the catalyst reaches 0.3, and stop injecting sulfide. Inject containing toluene and C 9 + The material of A is contacted with the catalyst for reaction, and the catalyst performance evaluation conditions are as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com