Method for preparing porous nickel-based ODS ( Oxide Dispersion Strengthened) alloy

A porous nickel and alloy technology, applied in the field of porous high-temperature alloy preparation, can solve the problems of poor sinterability, uneven particle size, serious work hardening, etc., and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

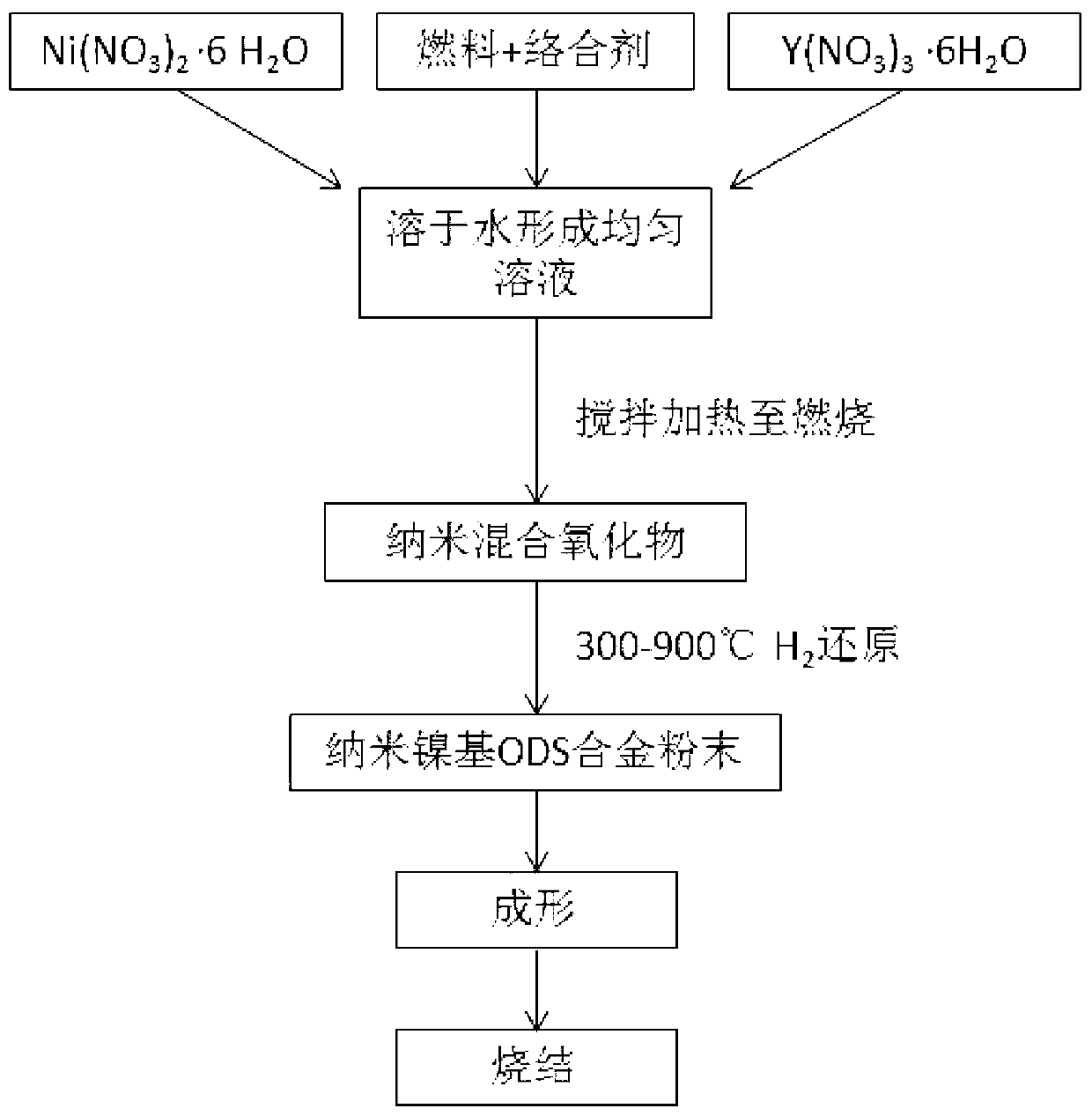

[0016] Example 1: 2wt%Y 2 O 3 Preparation of Ni-Cr-Based ODS Alloy with Content Porous

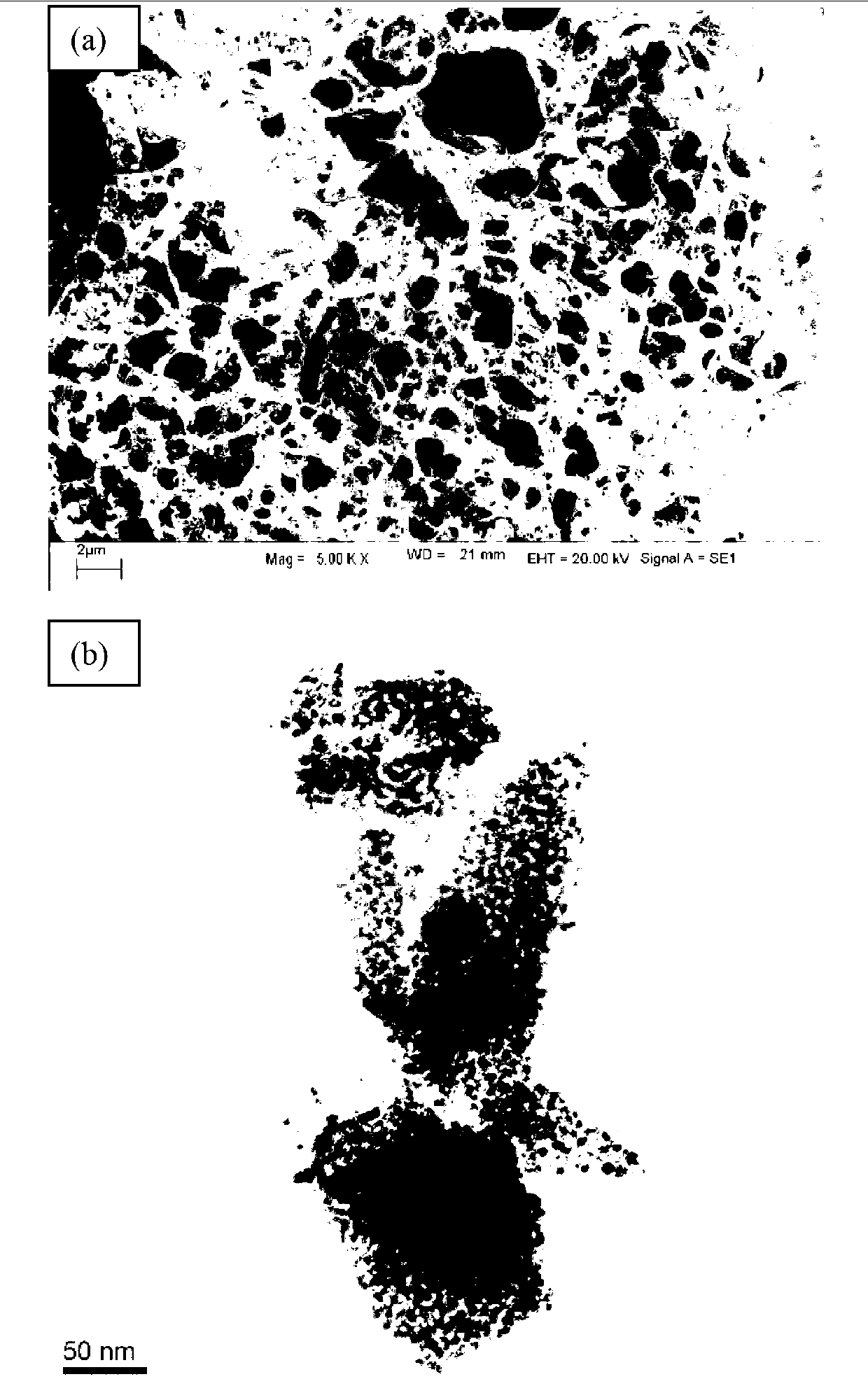

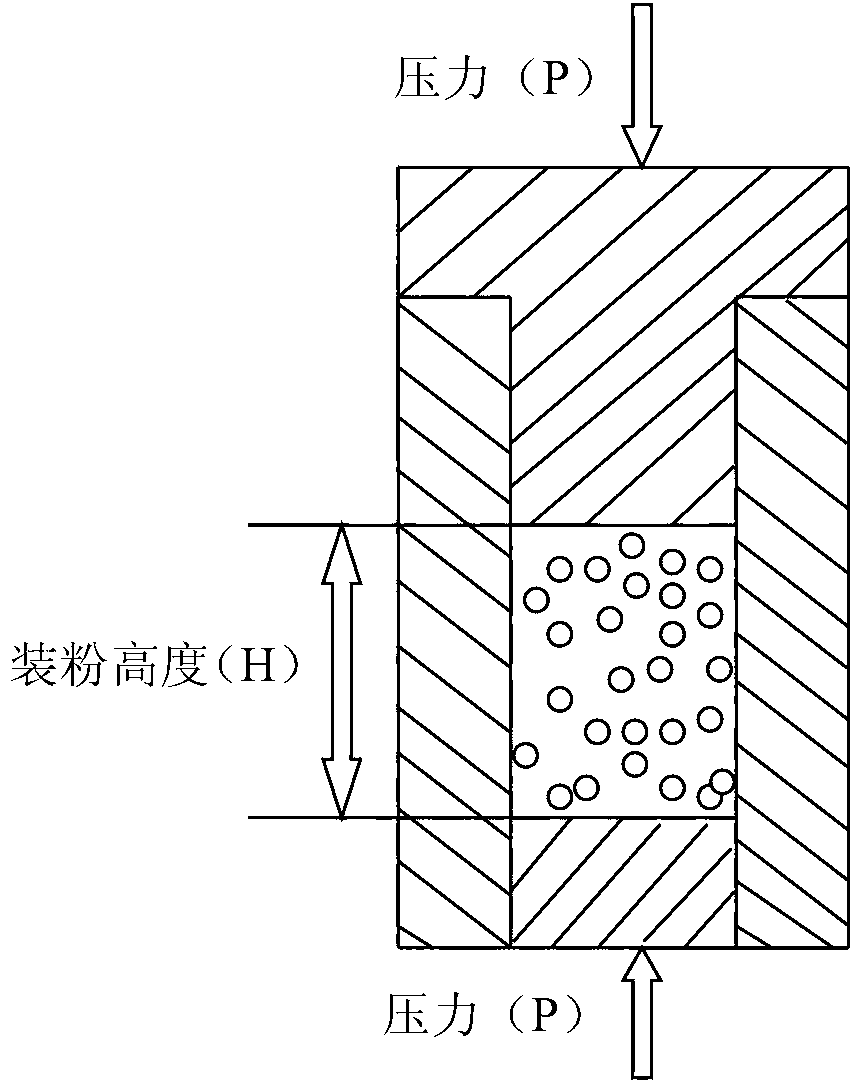

[0017] According to the composition of Ni-based ODS alloy Ni-2wt%Y 2 o 3 Weigh Ni (NO 3 ) 2 ·6H 2 O and Y (NO 3 ) 3 ·6H 2 O, add urea and NO 3 - The molar ratio of glucose to NO is 0.4 3 - The molar ratio of the raw material is 0.65. Dissolve the raw material powder in an appropriate amount of deionized water and stir until it is completely dissolved, then heat it on the electric furnace. During the heating process, do not stop stirring until a large amount of thick smoke comes out, and stop heating when the combustion is about to start. Let the combustion reaction continue spontaneously for 3-5 minutes to obtain nano-NiO+Y 2 o 3 Mix powder. Nano NiO+Y 2 o 3 The mixed powder was reduced in a hydrogen atmosphere at 500° C. for 2 hours to obtain nano-nickel-based ODS powder with an average particle size of 20 nm. Next, the obtained nano-nickel-based ODS powder was ...

Embodiment 2

[0018] Example 2: 4wt%Y 2 O 3 Preparation of Ni-Al-Based ODS Alloy with Content Porous

[0019] According to the composition of Ni-based ODS alloy Ni-4wt%Y 2 o 3 Weigh Ni (NO 3 ) 2 ·6H 2 O and Y (NO 3 ) 3 ·6H 2 O, add urea and NO 3 - The molar ratio of glucose to NO is 0.5 3 - The molar ratio of the raw material is 0.4. Dissolve the raw material powder in an appropriate amount of deionized water and stir until it is completely dissolved, then heat it on the electric furnace. During the heating process, do not stop stirring until a large amount of thick smoke comes out, and stop heating when the combustion is about to start. Let the combustion reaction continue spontaneously for 3-5 minutes to obtain nano-NiO+Y 2 o 3 Mix powder. Nano NiO+Y 2 o 3 The mixed powder was reduced in a hydrogen atmosphere at 700° C. for 2 hours to obtain nano-nickel-based ODS powder with an average particle size of 13 nm. Then the obtained nano-nickel-based ODS powder and bi...

Embodiment 3

[0020] Example 3: 8wt%Y 2 O 3 Preparation of Ni-Al-Based ODS Alloy with Content Porous

[0021] According to the composition of Ni-based ODS alloy Ni-8wt%Y 2 o 3 Weigh Ni (NO 3 ) 2 ·6H 2 O and Y (NO 3 ) 3 ·6H 2 O, add urea and NO 3 - The molar ratio of glucose to NO is 0.6 3 - The molar ratio of the raw material is 0.3. Dissolve the raw material powder in an appropriate amount of deionized water and stir until it is completely dissolved, then place it on the electric furnace for heating. During the heating process, do not stop stirring until a large amount of thick smoke comes out, and stop heating when the combustion is about to start. Let the combustion reaction continue spontaneously for 3-5 minutes to obtain nano-NiO+Y 2 o 3 Mix powder. Nano NiO+Y 2 o 3 The mixed powder was reduced in a hydrogen atmosphere at 500° C. for 2 hours to obtain nano-nickel-based ODS powder with an average particle size of 30 nm. Next, the obtained nano-nickel-based ODS p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com