Production method of pleurotus cornucopiae

A production method, the technology of Jiji mushroom, applied in botany equipment and methods, horticulture, application, etc., can solve the problems of insufficient one-time investment funds, large one-time investment, high production cost, etc., to reduce white pollution, reduce investment, Reduce the effect of upfront investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

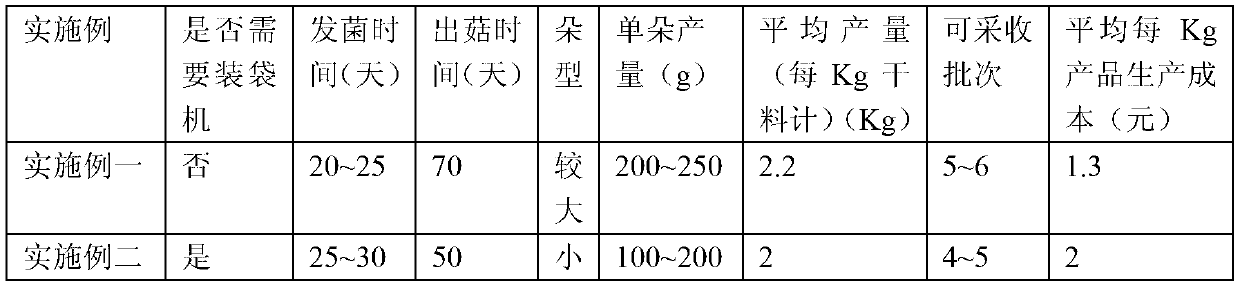

Examples

Embodiment 1

[0018] According to the formula (20% sawdust, 20% corn cob, 29% cottonseed hull, 30% bran, 1% lime, the above raw materials are the dry matter mass ratio after removing water, all raw materials are commercially available) and weighed to produce Jiji mushroom Various raw materials: sawdust 20Kg, corn cob 20Kg, cotton seed hull 29Kg, bran 30Kg (the above weights are based on the converted dry matter mass), after mixing, manually stir, add 1Kg of lime into water to dissolve and add to the compost, and stir evenly Add about 100Kg of water to adjust the water content of the compost to about 55% to 60%;

[0019] Put the mixed culture material into a degradable white plastic bag, and one person uses a shovel to shovel the material and the other supports the mouth. The material in each bag is about 6Kg. After filling, use a rope to tie the mouth. Satisfy the mycelium's demand for oxygen during the germination process;

[0020] Sterilize the filled plastic bags in an atmospheric press...

Embodiment 2

[0024] According to the formula (20% sawdust, 20% corn cob, 29% cottonseed hull, 30% bran, 1% lime, the above raw materials are the dry matter mass ratio after removing water, all raw materials are commercially available) and weighed to produce Jiji mushroom Various raw materials: sawdust 20Kg, corn cob 20Kg, cotton seed hull 29Kg, bran 30Kg (the above weights are based on the converted dry matter mass), after mixing, manually stir, add 1Kg of lime into water to dissolve and add to the compost, and stir evenly Add about 100Kg of water to adjust the water content of the compost to about 55% to 60%;

[0025] Use the bagging machine to pack the prepared culture material into bags. The cultivation bag is a polypropylene plastic bag with a specification of 17cm×33cm. Each bag contains 1Kg of wet material. The bagged fungus bag is put on a collar, and the middle of the fungus bag is punched. , cover the lid;

[0026] Put the packed bacteria bag into the normal sterilization pot for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com