Method for preparing feed-grade sodium selenite coated diluting agent

A sodium selenite, feed-grade technology, applied in animal feed, animal feed, applications, etc., can solve the problems of sodium selenite powder particle size change, high sodium selenite content, poor mixing uniformity, etc., to achieve Good coating effect, stable physical properties, and reduced difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

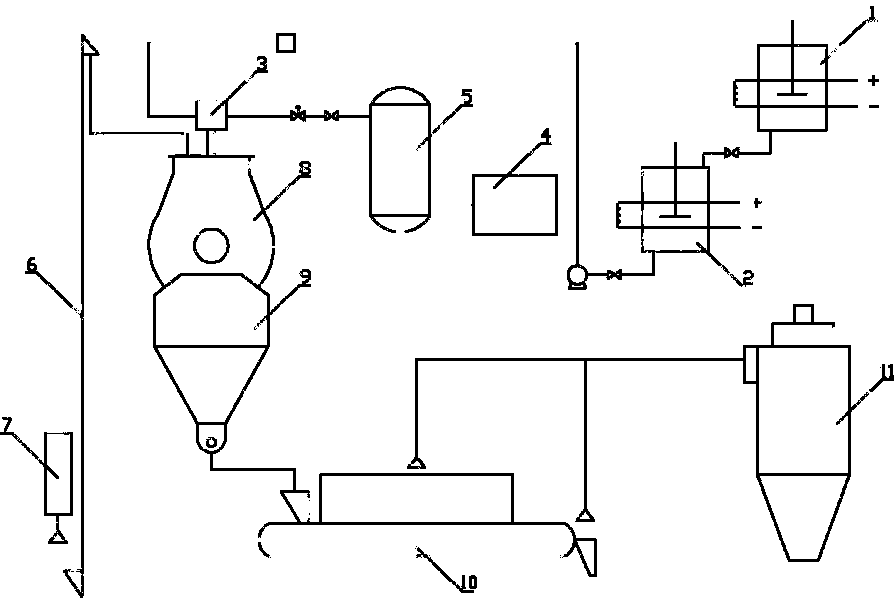

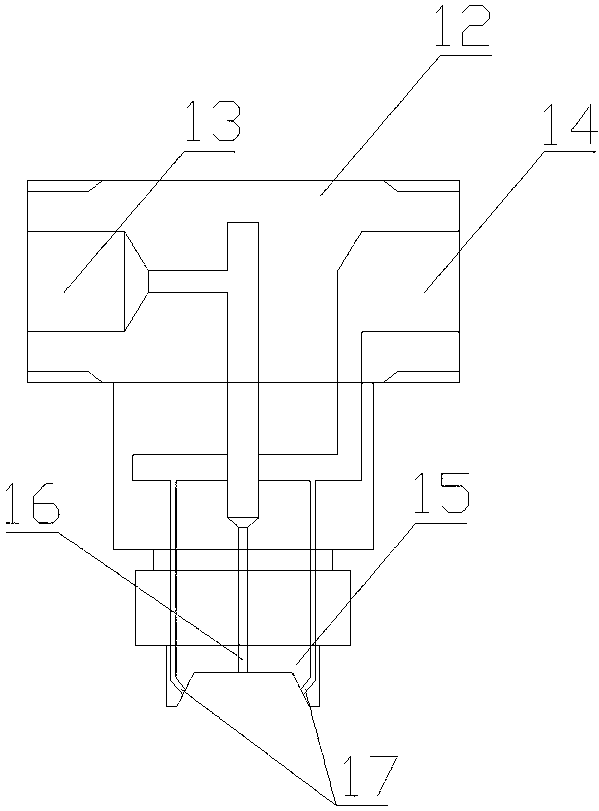

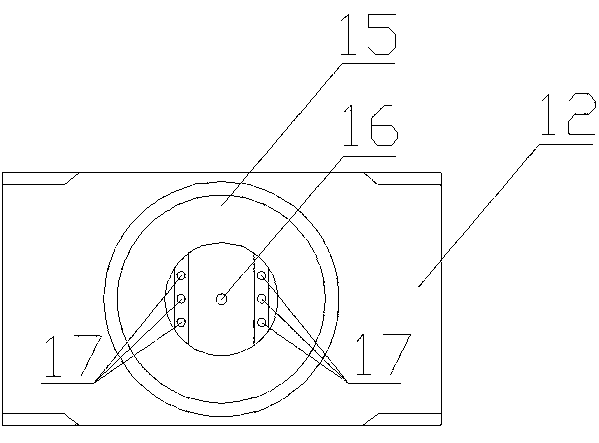

Method used

Image

Examples

Embodiment 1

[0045] A preparation method of a feed grade sodium selenite coating diluent, comprising the following processing steps:

[0046] A. Weighing of raw materials

[0047] Calculate and weigh feed grade sodium selenite, natural polymer coating material and carrier according to the sodium selenite content required by the product;

[0048] B. to dissolve

[0049] According to the sodium selenite content required by the product, the feed grade sodium selenite taken by weighing is completely dissolved in water to form a sodium selenite solution; Completely dissolve in water to form a natural polymer coating material solution;

[0050] C, mixing, heating and stirring

[0051] The sodium selenite solution obtained in step B is mixed with the natural polymer coating material solution obtained in step C, and heated and stirred, and the mixed solution is kept for standing after heating and stirring;

[0052] D. Coating, chimerism, dilution treatment

[0053] Add the carrier weighed in ...

Embodiment 2

[0057] A preparation method of a feed grade sodium selenite coating diluent, comprising the following processing steps:

[0058] A. Weighing of raw materials

[0059] Calculate and weigh feed grade sodium selenite, natural polymer coating material and carrier according to the sodium selenite content required by the product;

[0060] B. to dissolve

[0061] According to the sodium selenite content required by the product, the feed grade sodium selenite taken by weighing is completely dissolved in water to form a sodium selenite solution; Completely dissolve in water to form a natural polymer coating material solution;

[0062] C, mixing, heating and stirring

[0063] The sodium selenite solution obtained in step B is mixed with the natural polymer coating material solution obtained in step C, and heated and stirred, and the mixed solution is kept for standing after heating and stirring;

[0064] D. Coating, chimerism, dilution treatment

[0065] Add the carrier weighed in ...

Embodiment 3

[0069] A preparation method of a feed grade sodium selenite coating diluent, comprising the following processing steps:

[0070] A. Weighing of raw materials

[0071] Calculate and weigh feed grade sodium selenite, natural polymer coating material and carrier according to the sodium selenite content required by the product;

[0072] B. to dissolve

[0073] According to the sodium selenite content required by the product, the feed grade sodium selenite taken by weighing is completely dissolved in water to form a sodium selenite solution; Completely dissolve in water to form a natural polymer coating material solution;

[0074] C, mixing, heating and stirring

[0075] The sodium selenite solution obtained in step B is mixed with the natural polymer coating material solution obtained in step C, and heated and stirred, and the mixed solution is kept for standing after heating and stirring;

[0076] D. Coating, chimerism, dilution treatment

[0077] Add the carrier weighed in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com