Ultrasonic homogeneous mixing-proportioning device of multi-element metal powder

A multi-component metal and metal powder technology, applied in the field of powder metallurgy equipment, can solve the problems of uniformity, poor stability, poor fluidity, high agglomeration and bonding energy of pure molybdenum powder, etc., and achieve sufficient dispersion and homogeneity. , Component control precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

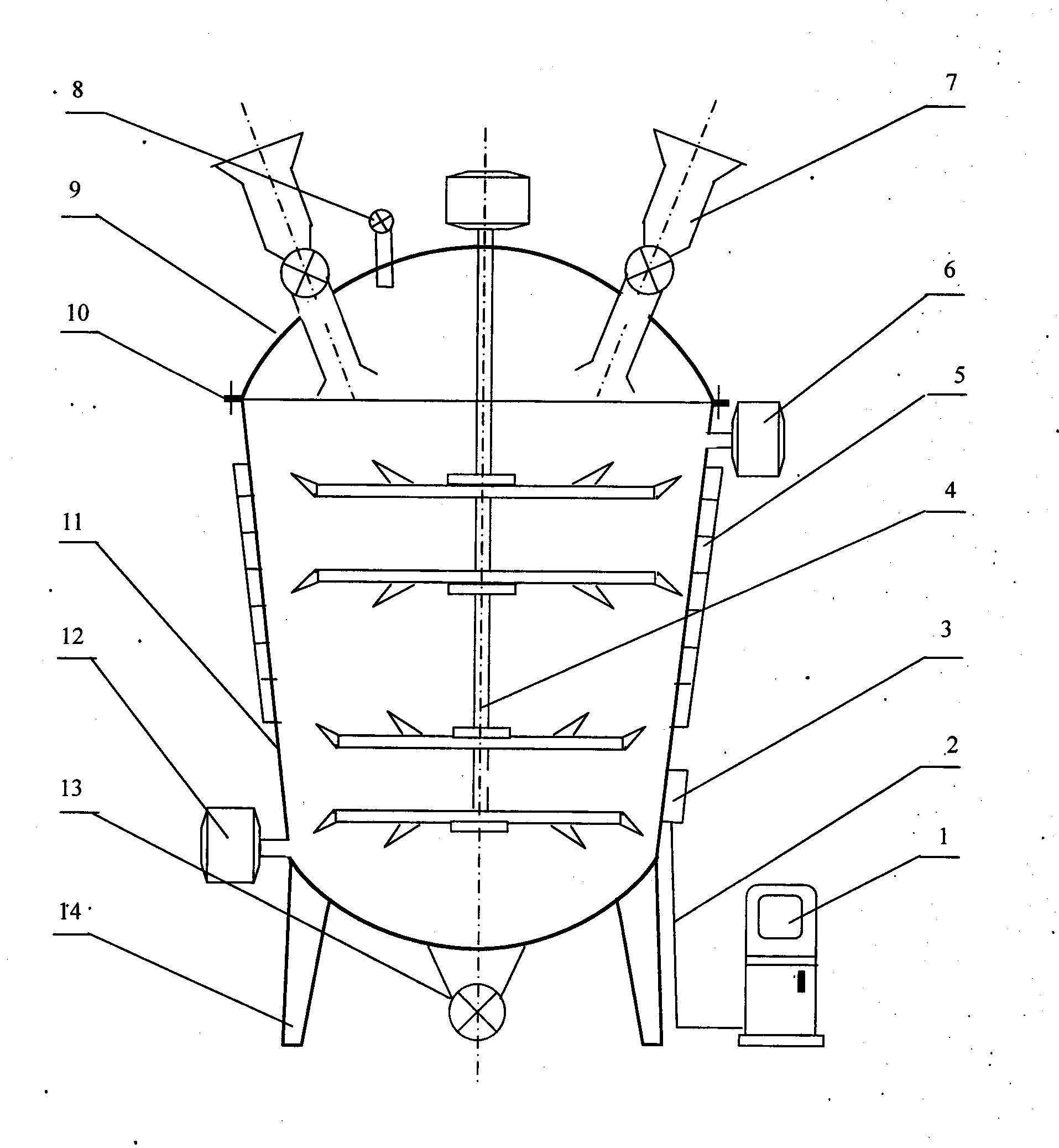

[0027] As shown in the figure, the multi-element metal powder ultrasonic homogeneous mixer includes a mixing tank, a plate ultrasonic transducer (5), a vacuum pump (6), a metal powder spray feeder (7), and a stirring disperser (4) , a hydrogen gas injection pump (12), an automatic control device (1), a discharge port (13), and a safety exhaust valve (8).

[0028] As shown in the accompanying drawings, the mixing tank is designed as a fully enclosed cone-shaped tank structure as a whole, consisting of a mounting bracket (14), a cone-shaped mixing tank body (11), and a dome-shaped mixing tank cover (9). Quickly open or close and fix by quickly connecting the flange (10); on the mixing tank cover (9), a stirring disperser (4), a metal powder spray feeder (7), a safety exhaust valve ( 8) and other operational functional parts; on the mixing tank body (11), there are installed and fixed a main junction box (3), a plate-type ultrasonic transducer (5), a vacuum pump (6), a hydrogen g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com