Bleaching liquid for dacron fabric and bleaching method of dacron fabric

A technology of polyester fabric and bleaching solution, which is applied in the direction of bleaching products, textile material processing, and continuous processing of textile materials, etc. It can solve the problems of limited use, strong metal corrosion, etc., and achieve damage prevention, simple bleaching process, and fabric strength. The effect of little damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation of Bleaching Solution for Polyester Fabric

[0045] Table 1: Formulation of bleaching solution for polyester fabric Unit: kg

[0046]

[0047]

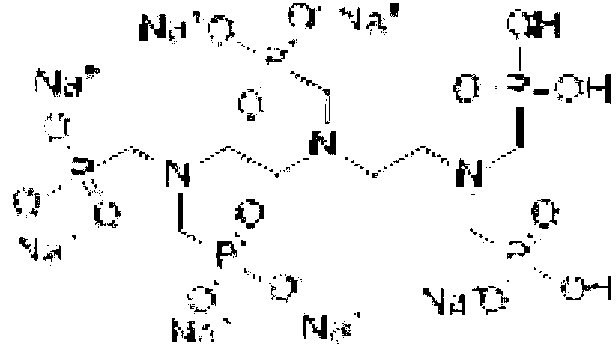

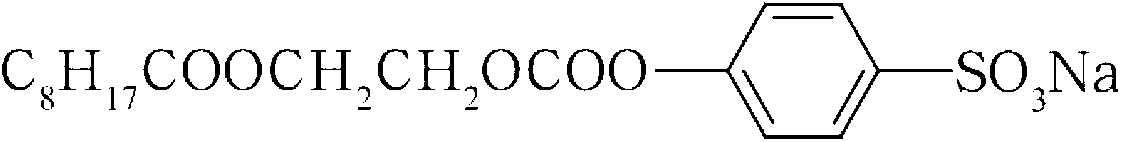

[0048] According to the corresponding data in Table 1, each raw material was weighed. Potassium borate, diethylenetriaminepentamethylenephosphonic acid heptasodium salt, acrylic acid-maleic acid copolymer, 1,5-anhydroglucitol, 4-(2-nonanoyloxyethoxy Dissolve sodium benzenesulfonate and tetraacetylethylenediamine in water, add sodium hydroxide and hydrogen peroxide, and mix evenly to obtain the bleaching solution for polyester fabrics.

Embodiment 2

[0056] Bleaching method of polyester fabric

[0057] At room temperature, the polyester fabric prepared in Example 1 was dipped with bleaching solution to pad the polyester fabric, and the liquid was squeezed to 100% with a liquid manipulator, then steamed at 100°C for 50 minutes, finally washed with water at room temperature for 30 minutes, and dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com