Reflection-type photoetching projection objective

A lithographic projection and reflective technology, which is applied to microlithography exposure equipment, optics, optical components, etc., can solve the problems of increased difficulty in manufacturing objective lenses, low exposure efficiency, and increased cost, achieving high transmittance and increased Effect of exposure illumination and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

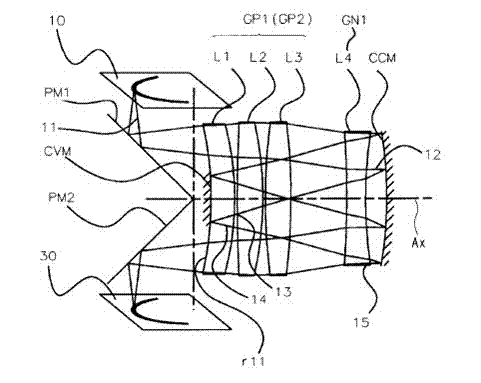

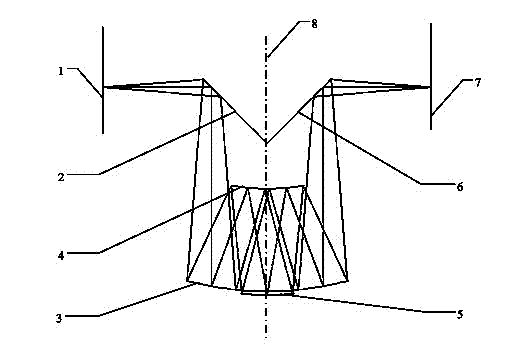

[0025] Projection objective lens optical system structure of the present invention such as figure 2 As shown, after the mask surface 1 is irradiated by illumination light, the light passing through the mask is reflected by the plane reflector 2 and then enters the spherical reflector 3. The plane reflector 2 makes the chief ray of each object point reflect at 90 degrees. The concave spherical mirror 3 has a positive power, so that the light falling on it can be partially converged and reflected. The light reflected from the spherical reflector 3 enters the spherical reflector 4, and the spherical reflector 4 has a negative power, so that the reflected light can enter the spherical reflector 5 in a divergent form. The light rays of each object point form a pupil surface on the spherical mirror 5 after passing through the above-mentioned optic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com