Local residual stress ultrasonic testing and closed-loop control device

A technology of residual stress and closed-loop control, applied in the direction of mechanical pressure/force control, non-electric variable control, control/regulation system, etc., which can solve the problem of limited size of processed materials, insignificant processing effect, difficult processing of in-service components, etc. problems, to achieve the effect of convenient operation, reasonable design and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention is described in detail as follows in conjunction with accompanying drawing:

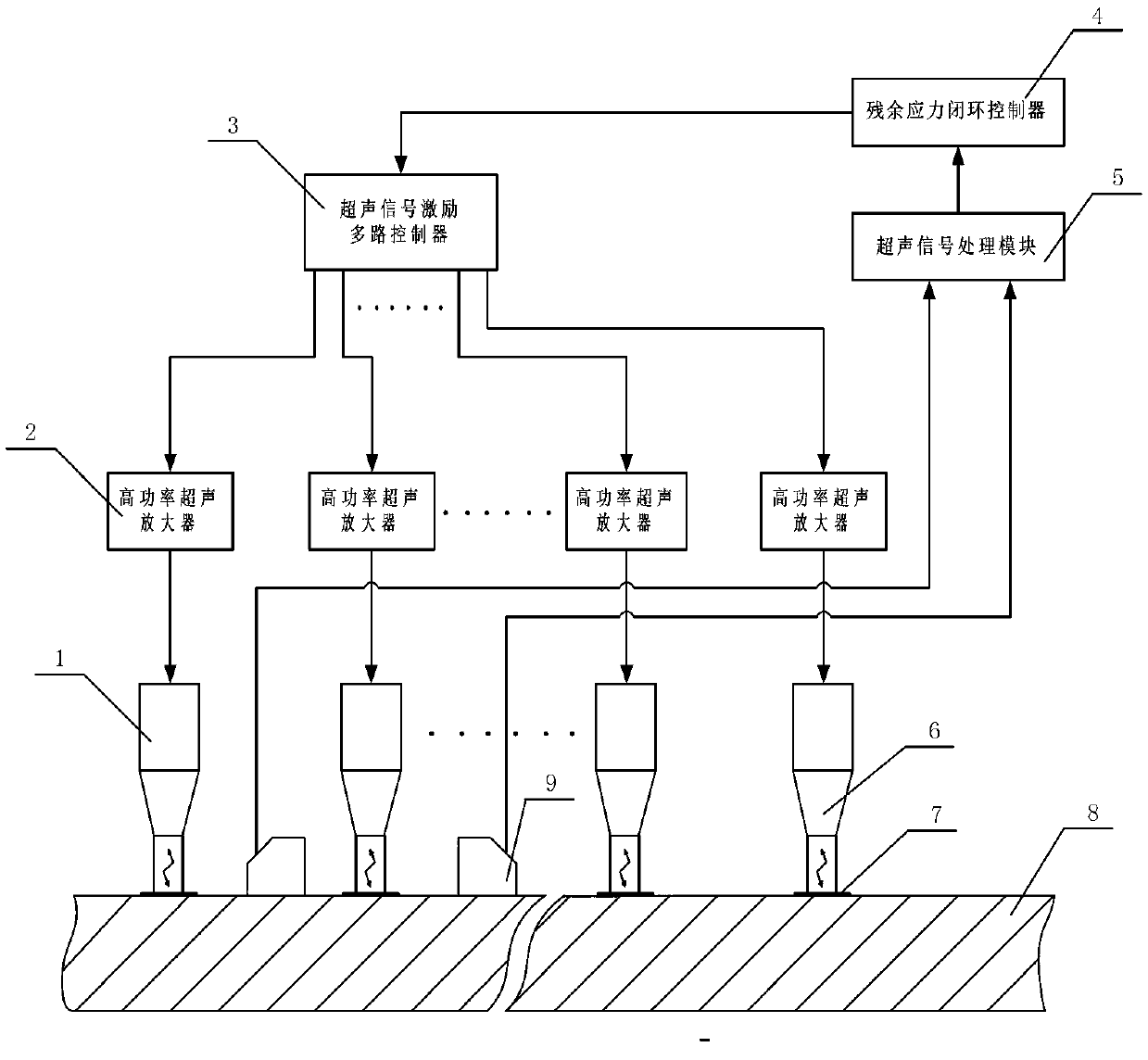

[0018] Such as figure 1 Shown is the principle diagram of the closed-loop control system of the present invention, which includes: high-energy ultrasonic transducer (1), high-power ultrasonic amplifier (2), ultrasonic signal excitation multi-channel controller (3), residual stress closed-loop controller ( 4), ultrasonic signal processing module (5), energy concentrator (6), coupling agent (7), workpiece (8), residual stress detection transducer (9). When adjusting the residual stress of a certain workpiece, the multi-channel controller (3) is first excited by the ultrasonic signal to cooperate with the software to control multiple high-power ultrasonic amplifiers (2) to generate driving signals, and the driving signals excite multiple high-energy ultrasonic transducers ( 1) Generate a high-energy ultrasonic beam, and focus the energy of the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com