Method for manufacturing insulated gate bipolar transistor (IGBT) component combined with fast recovery diode (FRD)

A device manufacturing method and multiple tube technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of large occupied area, large on-state voltage, high base resistance, etc. The effect of small state resistance and short fall delay time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

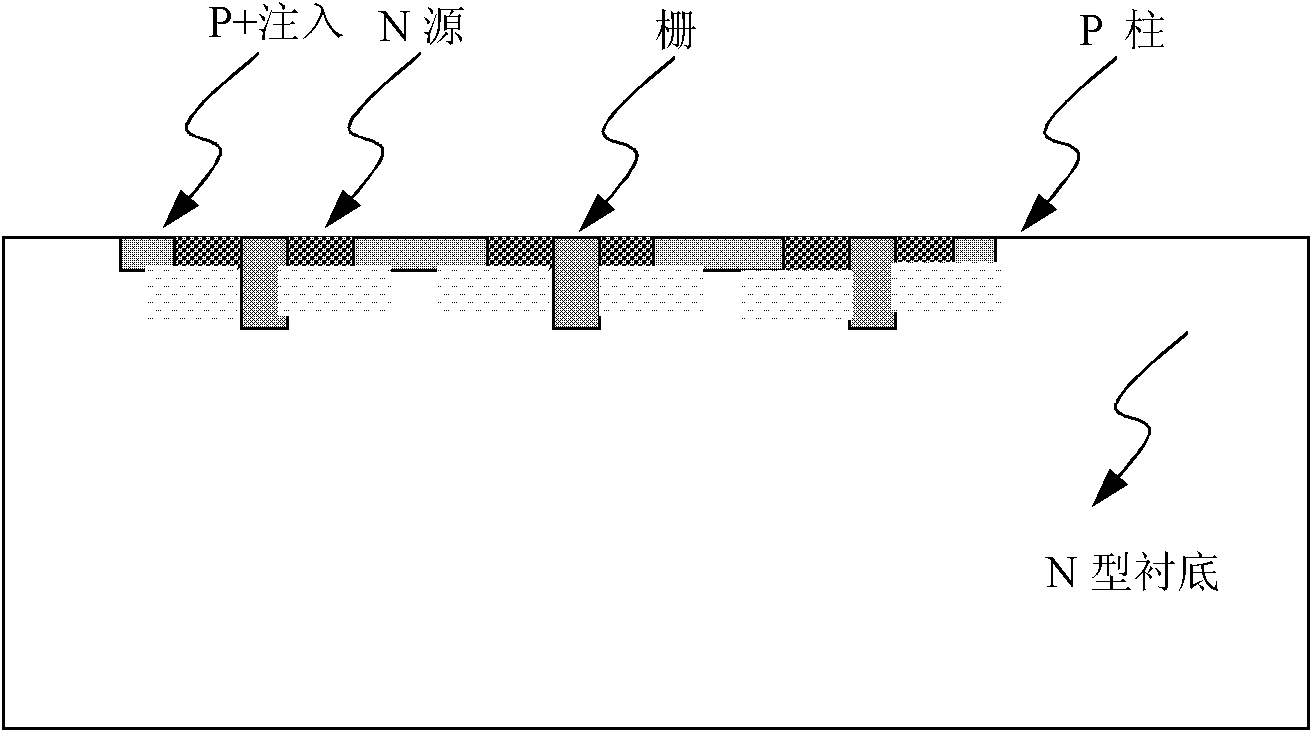

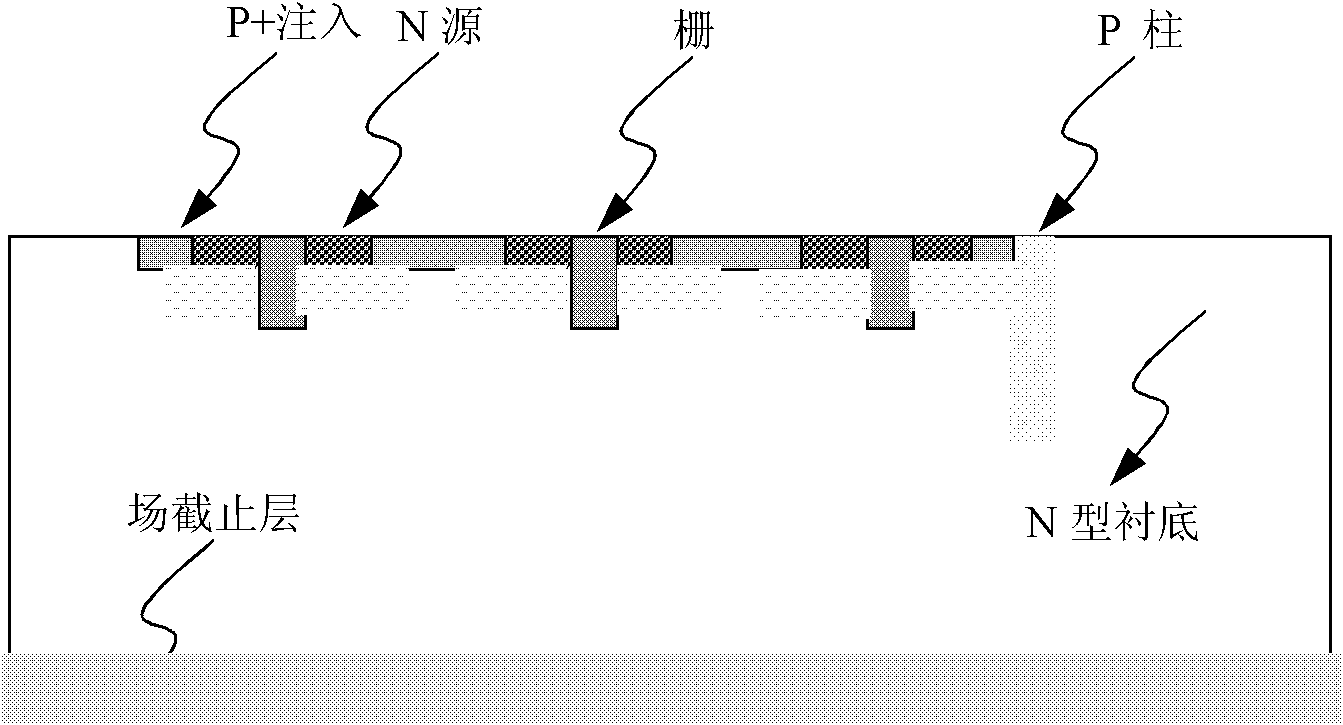

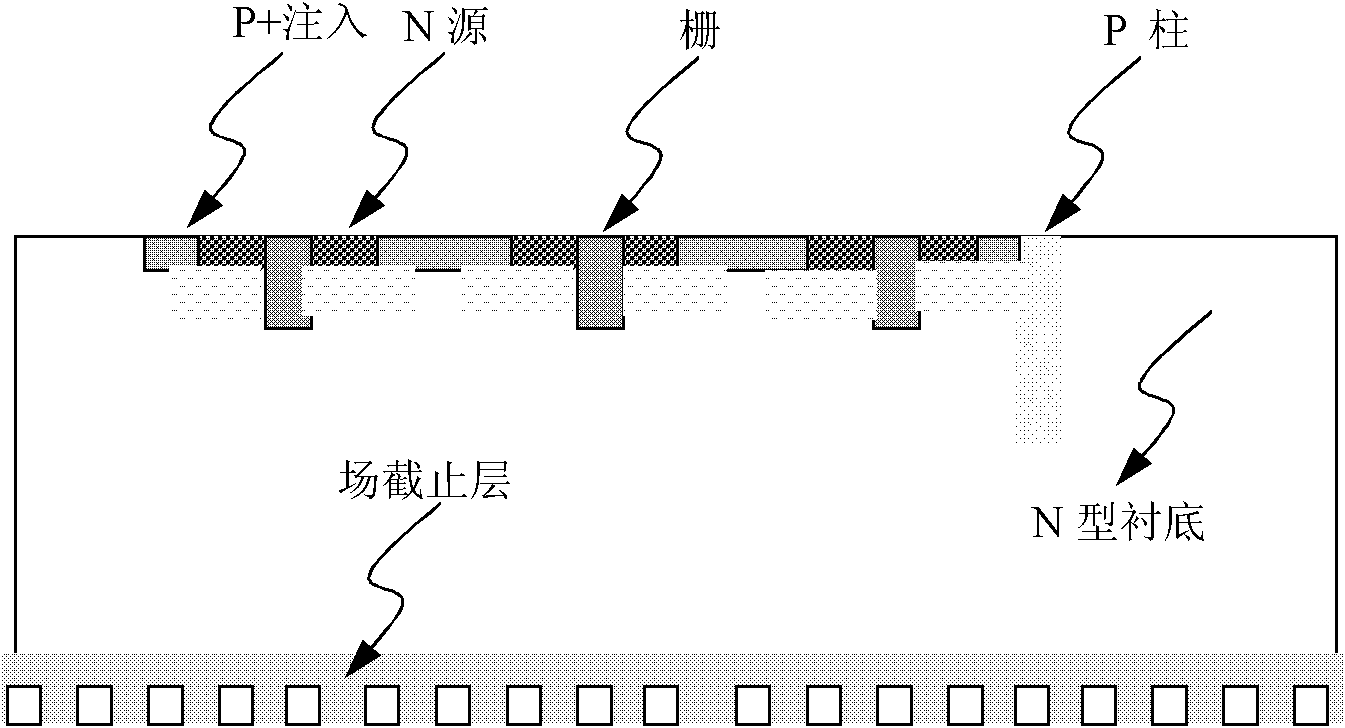

[0023] The present invention provides a special 8-inch device structure combined with a Fly-Trench trench field-stop insulated gate bipolar transistor IGBT. After the device is completed with an insulated gate bipolar transistor IGBT in the usual sense, it is then performed on the back side. The implantation of the field stop layer and the high temperature and long time push well to form the field stop layer, and then lithographically define the back side, trench trenches on the reverse side to grow highly doped polysilicon to form a reverse current path, and then the back side is injected and activated by the collector. And the extraction of the back metal to form the back collector.

[0024] The function of the present invention is to form the backside reverse voltage path by filling the backside trenches with N-type polysilicon, without worrying about the activation rate of N-type P ions, so that the process cost is greatly saved, and RC is integrated in the insulated gate bipo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com