Photovoltaic device in double-absorption-layer PIN structure and manufacture method thereof

A double-absorbing layer, photovoltaic device technology, applied in photovoltaic power generation, semiconductor devices, electrical components, etc., can solve the problem of low utilization of sunlight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

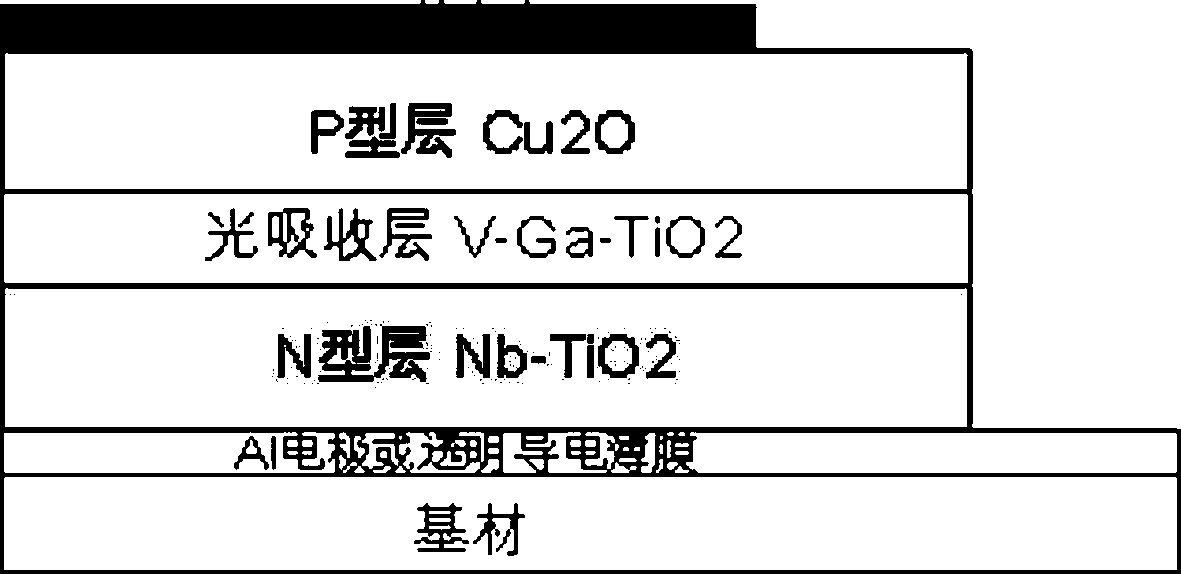

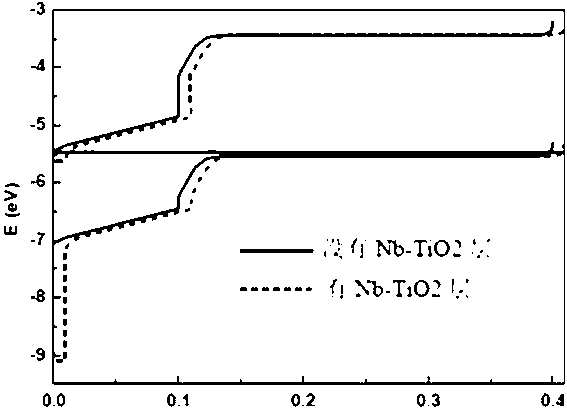

[0018] with attached figure 1 The device structure shown, select Nb:TiO 2 Doping concentration 1.7×10 21 cm -3 , thickness 10nm, intermediate layer (V-Ga:TiO 2 layer) with a doping concentration of 10 16 cm -3 , with a thickness of 100nm, Cu 2 O doping concentration 10 18 cm -3 , thickness 300nm.

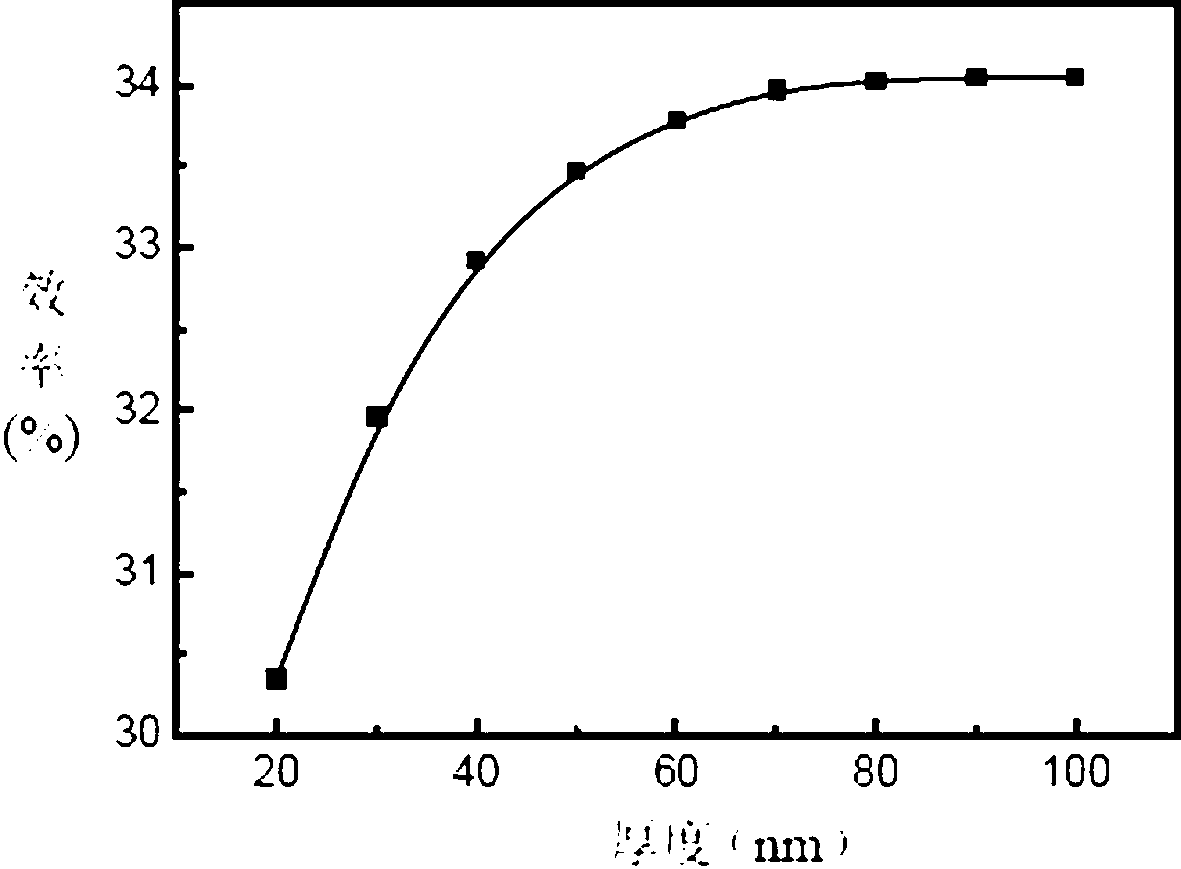

[0019] The battery efficiency under these parameters is simulated to be 34.12%, and the fill factor is 0.83.

Embodiment 2

[0021] with attached figure 1 The device structure shown, select Nb:TiO 2 Doping concentration 1.7×10 21 cm -3 , thickness 10nm, intermediate layer (V-Ga:TiO 2 layer) with a doping concentration of 10 18 cm -3 , with a thickness of 100nm, Cu 2 O doping concentration 10 18 cm -3 , thickness 300nm.

[0022] The battery efficiency under this parameter is simulated to be 34.121%, and the fill factor is 0.83.

Embodiment 3

[0024] Attached figure 1 The device structure shown, select Nb:TiO 2 Doping concentration 1.7×10 21 cm -3 , thickness 10nm, intermediate layer (V-Ga:TiO 2 layer) with a doping concentration of 10 12 cm -3 , with a thickness of 100nm, Cu 2 O doping concentration 10 18 cm -3 , thickness 300nm.

[0025] The battery efficiency under this parameter is simulated to be 34.136%, and the fill factor is 0.831.

[0026] All simulations use the standard solar spectrum of AM1.5 as the light source.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com