White light light-emitting diode device and encapsulation method without gold thread

A LED device, no gold wire technology, applied in semiconductor devices, electrical components, circuits, etc., to achieve the effect of reducing costs, efficient process, and solving heat dissipation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

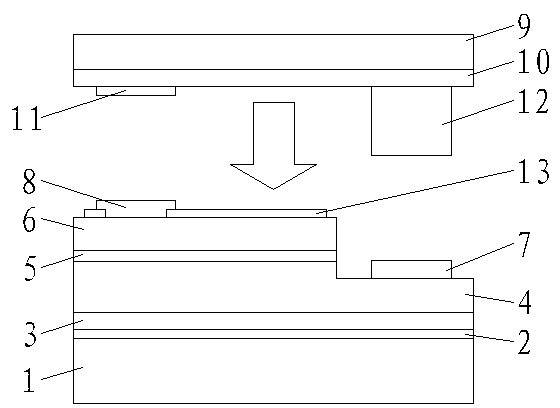

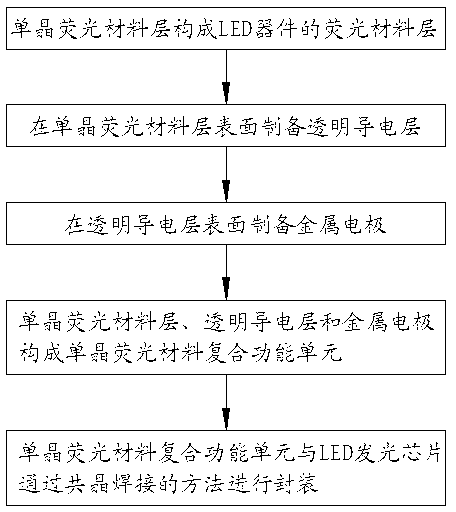

[0027] like figure 1 As shown, a white light LED device of the present invention includes a single crystal fluorescent material composite functional unit and an LED light-emitting chip, and the single crystal fluorescent material composite functional unit is arranged on one side of the LED light-emitting chip; the single crystal fluorescent material composite functional unit includes a single crystal The fluorescent material layer 9 , the transparent conductive layer 10 and the metal electrodes 11 and 12 , the single crystal fluorescent material layer 9 is arranged at one end of the transparent conductive layer 10 , and the metal electrodes 11 and 12 are arranged at the other end of the transparent conductive layer 10 . The LED light-emitting chip is stacked sequentially by the substrate layer 1, the buffer layer 2, the u-GaN layer 3, the n-GaN layer 4, the active region 5 and the p-GaN layer 6, and the n-GaN layer 4 is provided with an n-ohmic contact surface 7. A p-ohmic co...

Embodiment 2

[0039] The rest is the same as that of Embodiment 1, except that the single crystal material functional units are arranged on both sides of the LED light-emitting chip to form an LED device capable of emitting light from both sides.

Embodiment 3

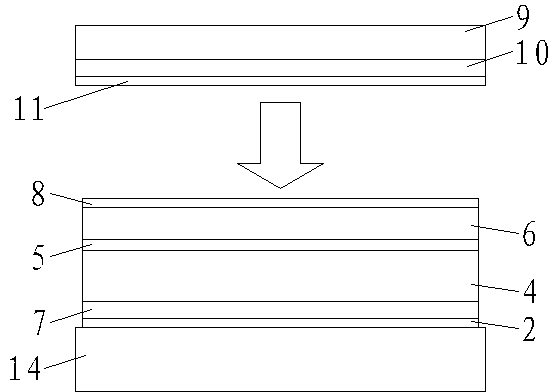

[0041] like image 3 As shown, the rest is the same as that of Embodiment 1, the difference is that it is a LED device with a vertical structure, including a single crystal fluorescent material composite functional unit and an LED light-emitting chip, and the single crystal fluorescent material composite functional unit consists of a single crystal fluorescent material layer 9, The transparent conductive layer 10 and the metal electrode 11 are stacked in sequence, and the LED light-emitting chip consists of a p-ohmic contact surface 8, a p-GaN layer 6, an active region 5, an n-GaN layer 4, an n-ohmic contact surface 7, and a buffer layer 2 Stacked with the base 14 in sequence, the process is simpler and more efficient, and it is helpful to arrange multiple LED light-emitting chips on one base 14, improving the luminous amount and luminous flux of a single LED device.

[0042]The beneficial effects of adopting this technical solution are: encapsulating white light LED devices d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com