Method for extracting lavender extract by adopting continuous countercurrent tube type ultrasonic waves

A technology of lavender extract and lavender, which is applied in the field of extracting lavender extract with continuous countercurrent tube ultrasonic extraction equipment, can solve the problems of low extraction rate, low recovery rate of organic solvents, and environmental pollution, so as to improve content and quality, Promote investment efficiency and demonstrate the effect of technological progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

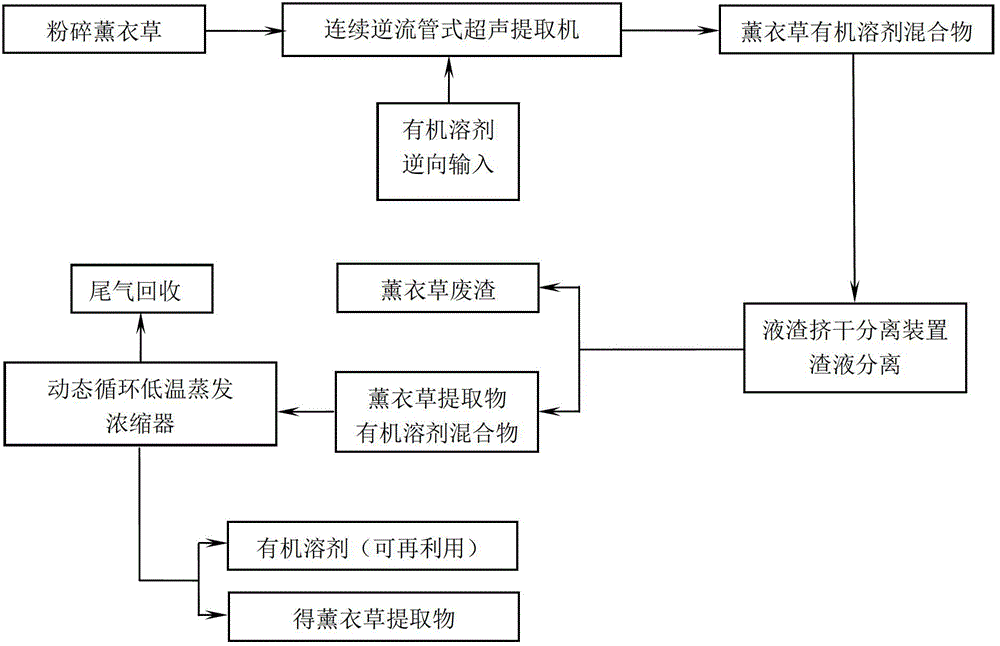

Image

Examples

preparation approach 1

[0023] Take 100kg of lavender that has been crushed through a 30-mesh sieve, input it into a continuous countercurrent tubular ultrasonic extraction machine that meets the national standard of JB / T 20126-2009 at a speed of 100kg / h, and input it reversely at a flow rate of 800L / h Xinjiang Jieple Biotechnology Co., Ltd. The produced organic solvent ethanol (95%) was extracted for 35 minutes while maintaining the temperature of the ultrasonic extraction tube at 40 °C to obtain a lavender ethanol mixture; after the mixture was input into the extraction liquid residue squeeze-drying separation device, the residue and the extraction mixture were separated; The mixture was input into a dynamic circulation low-temperature decompression (-0.08MPa) evaporative concentrator, the temperature was maintained at 35°C, and the organic solvent ethanol was evaporated and recovered for reuse, and 17 kg of the remaining extract was collected, which was the lavender extract, and the yield was 17...

preparation approach 2

[0025] Take 100kg of lavender crushed through a 30-mesh sieve, input it into a continuous countercurrent tubular ultrasonic extraction machine that meets the national standard of JB / T 20126-2009 at a speed of 100kg / h, and reversely input it into Tianjin Fuyu Fine Chemical Co., Ltd. at a flow rate of 1000L / h. The organic solvent ethyl acetate was extracted for 40 min while maintaining the temperature of the ultrasonic extraction tube at 45 °C to obtain a lavender ethyl acetate mixture; after the mixture was input into the extraction liquid residue squeezed and dried separation device, the residue and the extraction mixture were separated, and the extraction mixture was separated. Input into the dynamic circulation low temperature decompression (-0.08MPa) evaporative concentrator, keep the temperature at 40 ℃, the organic solvent ethyl acetate is evaporated and recovered and reused, and 15kg of the remaining extract is collected, which is the lavender extract, and the yield is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com