Method of removing organic impurities in hydrogen peroxide

A technology for hydrogen peroxide and organic impurities, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, etc., can solve the problem of short service life, energy Consumption and other problems, to achieve the effect of reducing energy consumption, saving investment, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

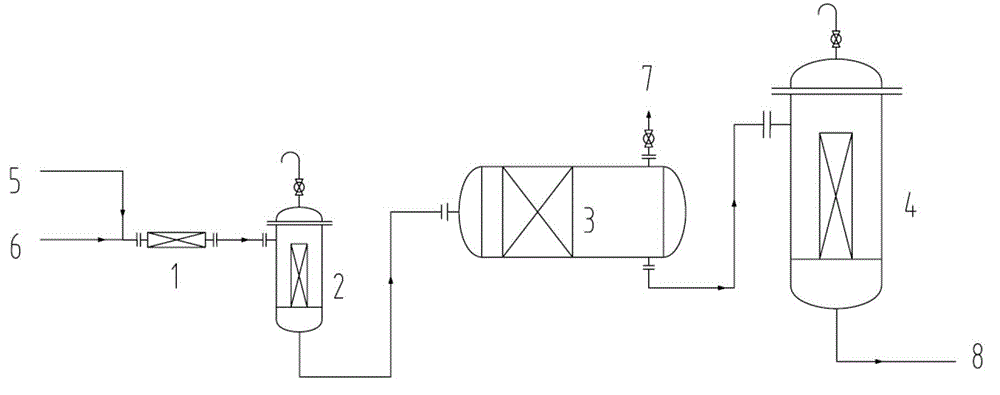

[0038] see figure 1 , the temperature is 30℃ and the flow rate is 5m 3 / h organic impurity content is 350ppm hydrogen peroxide aqueous solution 5 and flow rate is 3m 3 / h solvent trimethylene 6 enters the static mixer 1 at the same time for strong mixing. The mixing time is less than 1min, the temperature is 30°C, and the pressure is 0.3MPa;

[0039] Then the mixture of the two first enters the first filter 2 with a filtration accuracy of 5 microns to remove the solid particles, the filtration temperature is 30 ° C, and the pressure is less than or equal to 0.3 MPa;

[0040] After filtering, it enters the coalescer group 3, and through collision, coalescence, sedimentation, and separation, the separated solvent 7 containing organic impurities flows out from the top, and the aqueous hydrogen peroxide solution flows out from the bottom into the second filter 4. Coalescer group 3 consists of two coalescers connected in series. The coalescing packing in each coalescer is made ...

Embodiment 2

[0043] see figure 1 , the temperature is 20℃ and the flow rate is 3m 3 / h organic impurity content is 350ppm hydrogen peroxide aqueous solution 5 and flow rate is 3m 3 / h solvent trimethylene 6 enters the static mixer 1 at the same time for strong mixing. The mixing time is less than 1min, the temperature is 20°C, and the pressure is 0.3MPa;

[0044] Then the mixture of the two first enters the first filter 2 with a filtration accuracy of 5 microns to remove the solid particles, the filtration temperature is 20°C, and the pressure is less than or equal to 0.3MPa;

[0045] After filtering, it enters the coalescer group 3, and through collision, coalescence, sedimentation, and separation, the separated solvent 7 containing organic impurities flows out from the top, and the aqueous hydrogen peroxide solution flows out from the bottom into the second filter 4. Coalescer group 3 consists of two coalescers connected in series. The material of the coalescing packing in each coale...

Embodiment 3

[0048] see figure 1 , the temperature is 25℃ and the flow rate is 1m 3 / h organic impurity content is 350ppm hydrogen peroxide aqueous solution 5 and flow rate is 5m 3 / h The solvent mesitylene 6 enters the static mixer 1 at the same time for intensive mixing. The mixing time is less than 1min, the temperature is 25°C, and the pressure is 0.3MPa;

[0049] Then the mixture of the two first enters the first filter 2 with a filtration accuracy of 2 microns to remove the solid particles, the filtration temperature is 25 ° C, and the pressure is less than or equal to 0.3 MPa;

[0050] After filtering, it enters the coalescer group 3, and through collision, coalescence, sedimentation, and separation, the separated solvent 7 containing organic impurities flows out from the top, and the aqueous hydrogen peroxide solution flows out from the bottom into the second filter 4. The coalescer group 3 is composed of two coalescers in series, and the coalescing filler in each coalescer is m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com