Purifying treatment and recycling process for high-salt-content reclaimed water

A purification treatment, high-salt technology, applied in neutralized water/sewage treatment, adsorption water/sewage treatment, water/sewage multi-stage treatment, etc. Problems such as poor operability, to achieve the effect of high utilization rate of the drug, reducing the dosage of the drug, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

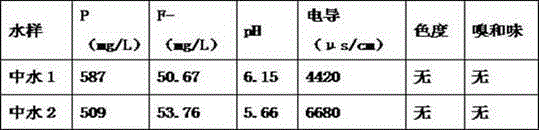

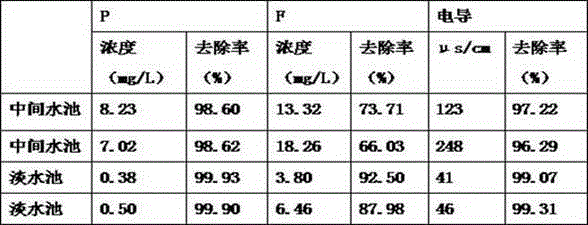

[0016] According to the present invention, Wengfu (Group) Co., Ltd. newly built a pilot plant and passed the pilot test. The calcium sulfate salts in the treated water are saturated and supersaturated, the hardness reaches 35-42mmoi / l, and the conductivity reaches 4000-8000μs / cm. obtained a good outcome.

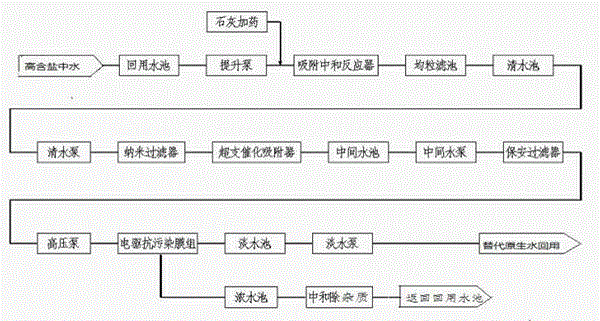

[0017] Technological process: (1) Let the high-salt reclaimed water flow into the reuse pool, then pump it into the adsorption neutralization reactor by the lift pump and add lime for clarification, and then let it flow into the homogeneous particle filter;

[0018] (2) The water clarified and filtered in the previous step enters the clean water tank, and is pumped into the nano filter by the clean water pump for further purification treatment. After passing through the nano filter, the water with residual pressure enters the overbranched catalytic adsorber to remove the pollution that is easy to block the membrane After factoring into the intermediate pool, the role of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com