Symmetrical double-rotation blasting method

A symmetrical, cooling tower technology, applied in the field of blasting, can solve the problems of poor disintegration effect of cooling towers, damage to surrounding facilities, large processing workload, etc., and achieve the effect of reducing demolition cost, workload and cost of demolition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

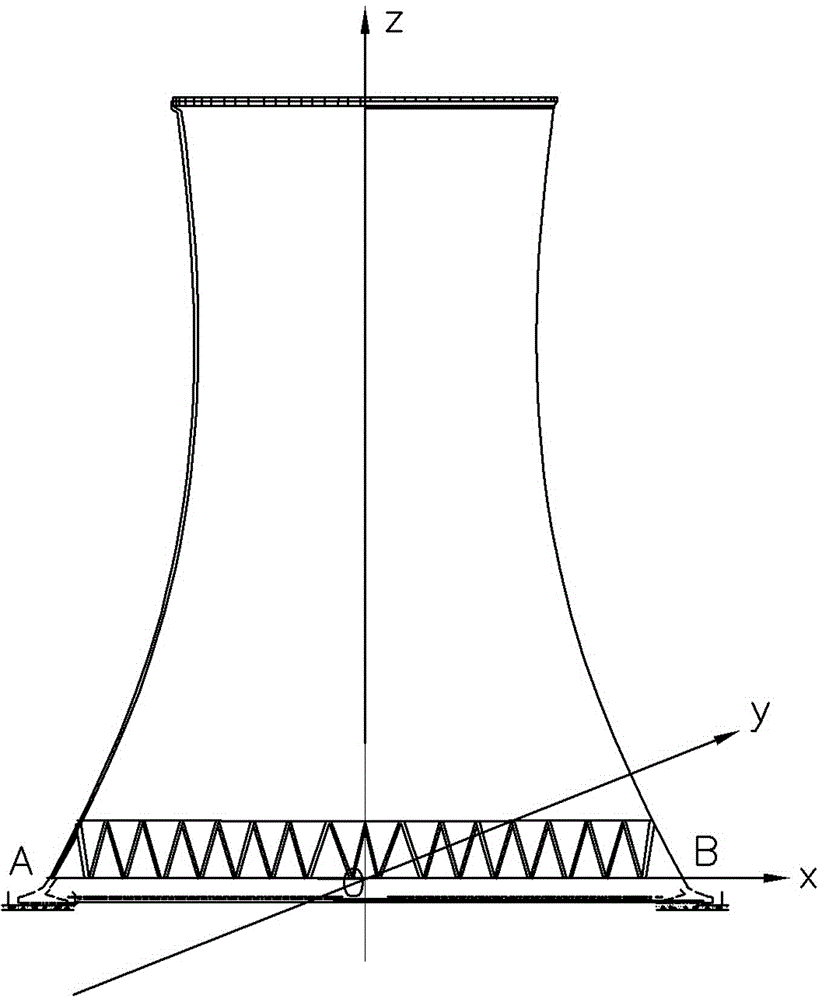

[0022] The invention provides a symmetrical swing blasting method, which comprises the following steps:

[0023] (1) Remove all structures inside the cooling tower;

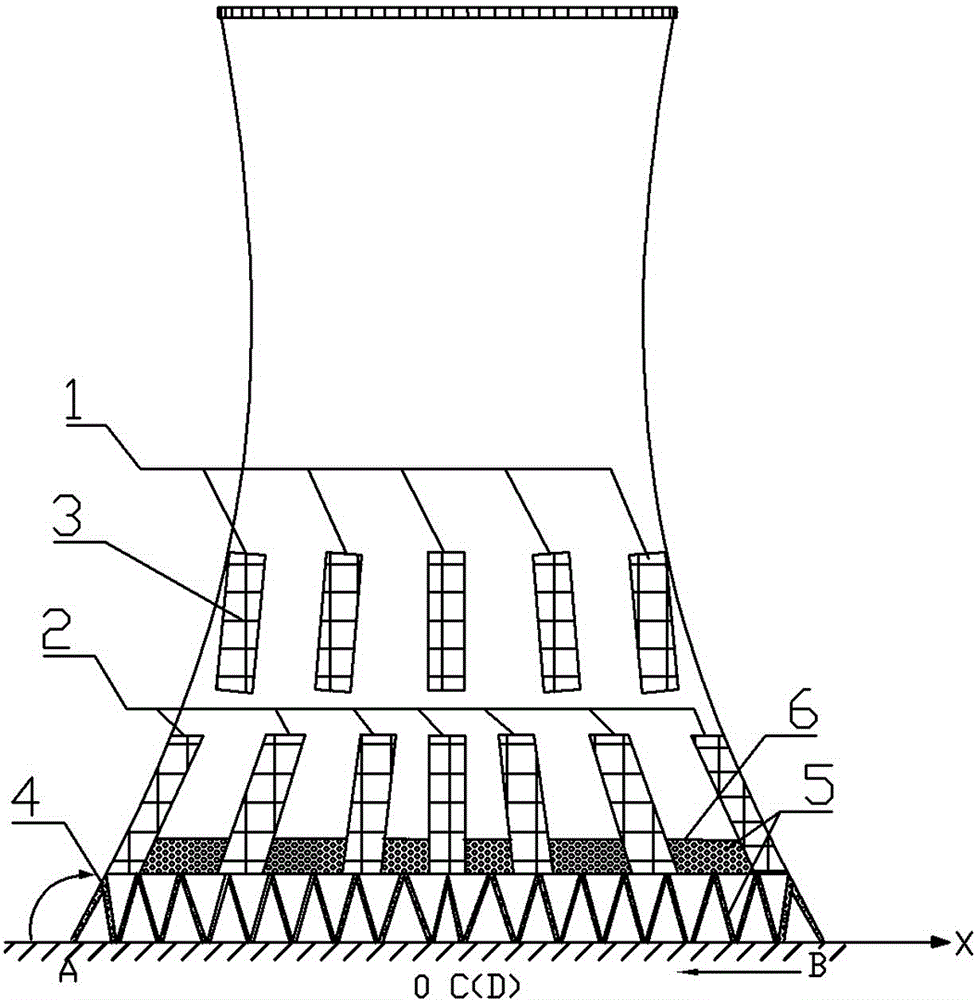

[0024] (2) Set the load-relief window 2 on the cooling tower ring beam 6 and its upper cylinder, and set the disassembly window 1 on the upper part of the load-relief window 2;

[0025] (3) Arrange a blasthole 5 on the ring beam 6 between the herringbone leg 4 and the unloading window 2, and install the nonel detonator and explosive in the blasthole 5;

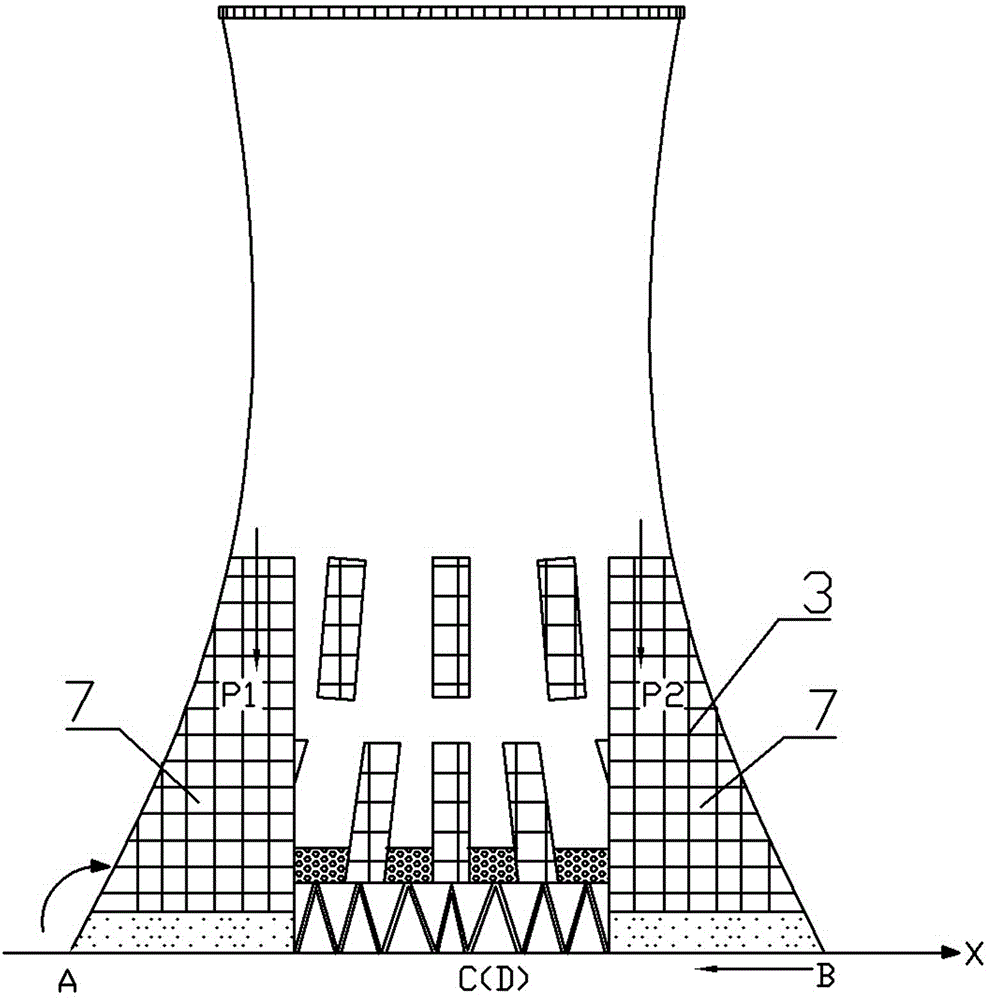

[0026] (4) Simultaneously ignite and detonate at two gun positions symmetrical to the center of the cooling tower bottom, and the two detonation points rotate symmetrically clockwise or counterclockwise at the same time to form two instantaneous detonations

Embodiment 2

[0028] The invention provides a symmetrical swing blasting method, which comprises the following steps:

[0029] (1) Remove all structures inside the cooling tower;

[0030] (2) Set the load-relief window 2 on the cooling tower ring beam 6 and its upper cylinder, and set the disassembly window 1 on the upper part of the load-relief window 2;

[0031] (3) Arrange a blasthole 5 on the ring beam 6 between the herringbone leg 4 and the unloading window 2, and install the nonel detonator and explosive in the blasthole 5;

[0032] (4) Simultaneously ignite and detonate at two gun positions symmetrical to the center of the cooling tower bottom, and the two detonation points rotate symmetrically clockwise or counterclockwise at the same time to form two instantaneous detonations.

[0033] The height of the top of the dismantled window 1 from the ground in step (2) is 20%-25% of the height of the cooling tower.

[0034] The load-reducing window 2 described in step (2) has a width of ...

Embodiment 3

[0037] The symmetrical swing blasting method for dismantling the cooling tower provided by the invention comprises the following steps:

[0038] (1) Remove all structures inside the cooling tower;

[0039] (2) Set the load-reducing window 2 on the cooling tower ring beam 6 and its upper cylinder, and set the dismantling window 1 on the upper part of the load-reducing window 2; the height of the top of the dismantling window 1 from the ground is 20% of the height of the cooling tower; The width of the load-reducing window 2 is 1.5 meters, and the spacing is 9 meters; the width of the dismantling window is 1.5 meters, and the spacing is 9 meters. After the form is set, the steel bar 3 is exposed

[0040] (3) Arrange a blasthole 5 on the ring beam 6 between the herringbone leg 4 and the unloading window 2, and install the nonel detonator and explosive in the blasthole 5;

[0041] (4) Simultaneously ignite and detonate at two gun positions symmetrical to the center of the coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com