Halogen seepage-free adhesive and its preparation method and use

A technology of adhesives and thickeners, applied in the production of halide-free straw flowerpots, the field of preparation of melamine-urea-formaldehyde copolymer glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

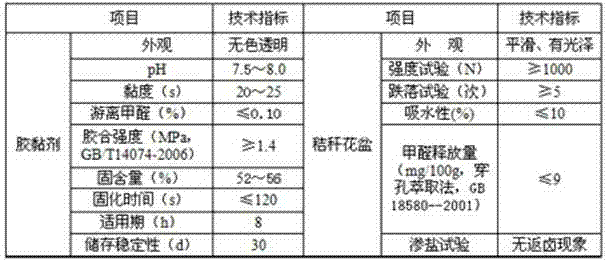

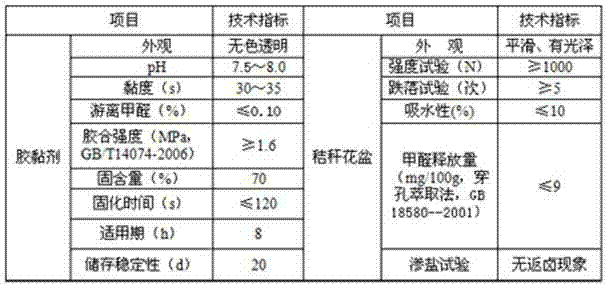

Image

Examples

Embodiment 1

[0041] Urea 1089g; Melamine 272g; 37% (W / W) formaldehyde solution 2207g.

[0042] The thickener is 35g of polyvinyl alcohol; the free formaldehyde scavenger is a mixture of 80g of corn starch and 40g of soybean powder.

[0043] The alkaline solution is 25% ammonia water; the acidic solution is 20% formic acid solution.

[0044] The straw powder is corn straw powder, appropriate amount.

[0045] First, put 2207g of the measured 37% (W / W) formaldehyde solution into the reactor at one time, adjust the pH value to 8.5 with alkaline solution, add 32.6 g of thickener polyvinyl alcohol and 49.0 g of the first batch of melamine, Start to heat up; raise the temperature to 40°C, add the first batch of urea 742.4 g, continue to heat up to 60°C, keep warm at 60°C for 20 minutes; adjust the pH value to 7.5 with alkaline solution, add the second batch of urea 346.6 g, and within 30 minutes Raise the temperature to 90°C, keep it warm at 90°C for 40 minutes; adjust the pH value to 8.5 with ...

Embodiment 2

[0063] Urea 1138.4 Kg; melamine 221.8 kg; 37% (W / W) formaldehyde solution 2000 kg.

[0064] The thickener is 17.1 kg of polyvinyl alcohol; the free formaldehyde scavenger is a mixture of 68.3 kg of corn starch and 68.3 kg of soybean flour.

[0065] The alkaline solution is 20% sodium hydroxide solution; the acidic solution is 20% formic acid solution.

[0066] Straw powder is wheat straw powder, appropriate amount.

[0067] First, put 2000 kg of measured 37% (W / W) formaldehyde solution into the reactor at one time, adjust the pH value to 8.5 with alkaline solution, add 17.1 kg of thickener polyvinyl alcohol and the first batch of melamine 41.0 kg , start to heat up; raise the temperature to 40°C, add the first batch of urea 643.5 kg, continue to raise the temperature to 60°C, keep time at 60°C for 20 min; adjust the pH value to 7.5 with alkaline solution, add the second batch of urea 494.9 kg, and Raise the temperature to 90°C within 30 minutes, and keep at 90°C for 40 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com