Method for manufacturing flexible-substrate-based self-encapsulation passive wireless pressure sensor

A technology of pressure sensors and flexible substrates, which is applied in the direction of instruments, measuring forces, and measuring devices, can solve the problems of inferior mechanical properties to flexible substrates, limiting the overall characteristics of devices, and difficulty in obtaining quality factors, etc., to achieve mass production, Easy to implement and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] The preparation method of the self-encapsulated passive wireless pressure sensor based on the flexible substrate of the present invention comprises the following steps:

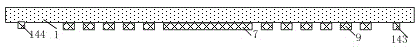

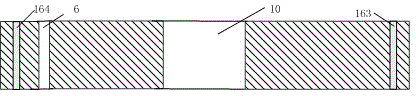

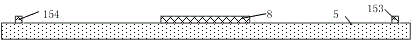

[0028] Step 10) Prepare upper flexible substrate 1: as figure 1 As shown, a flexible substrate is selected, and then an upper metal layer 2 is electroplated on the lower surface of the flexible substrate, and an etching process is used to photolithographically form a capacitor upper plate 7 on the upper metal layer 2 with internal connecting lines. 11 and the planar inductance coil 9 of the external connecting wire 12, and the first upper metal pillar 141, the second upper metal pillar 142, the third upper metal pillar 143 and the fourth upper metal pillar 144. The inner connecting wire 11 of the planar inductance coil 9 is connected with the upper plate 7 of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com