Super-diffraction nano-optical probe

A nano-optics and super-diffraction technology, applied in the field of bow-tie structure, can solve the problems that restrict the photolithographic resolution of SNOM probes, and achieve the effect of simple structure and cheap materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the scope of protection of the present invention is not limited to the following examples, but should include all content in the claims.

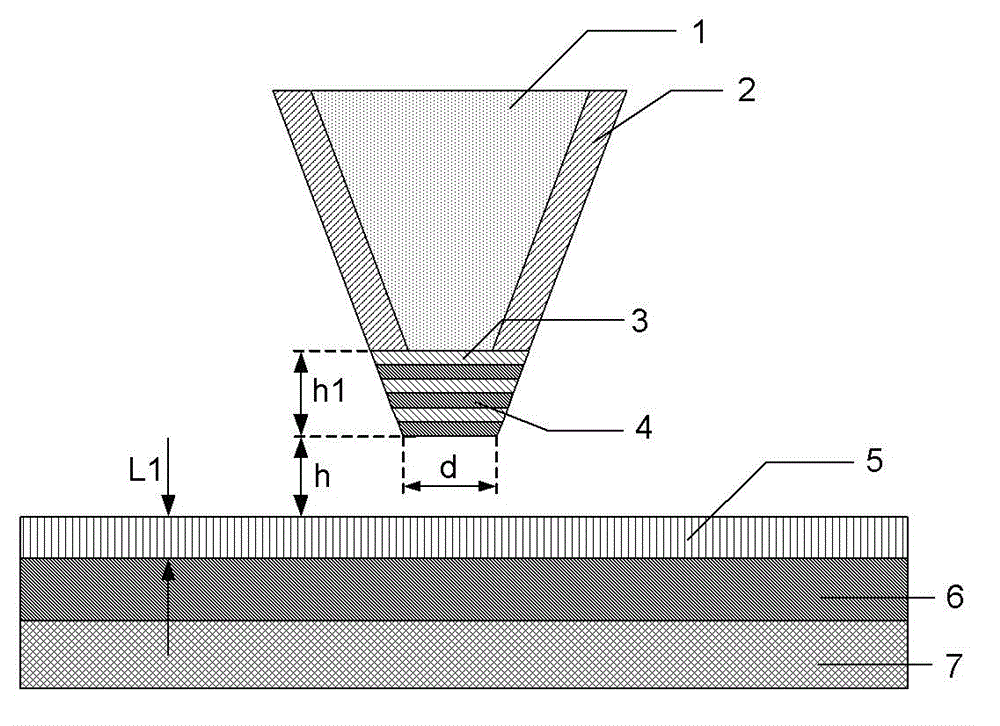

[0011] see figure 1 , is a cross-sectional view of the structure of the superdiffraction nano-optical probe included in the present invention, the optical probe includes a tapered dielectric core 1, a metal outer cladding 2, a dielectric film 3 and a metal film layer 4, and the tapered dielectric core 1 The top is a platform-shaped tapered tip; a layer of metal outer cladding 2 is coated on the outer surface of the tapered dielectric core 1, and a multilayer film is deposited on the surface of the tapered needle tip. The multilayer film is composed of alternately arranged dielectric films 3 and the metal film layer 4, when the light is vertically incident on the surface of the dielectric film 3, surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com