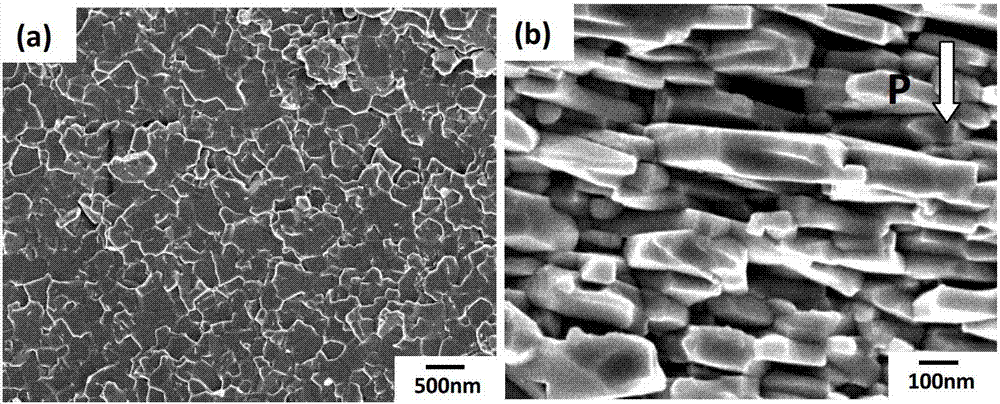

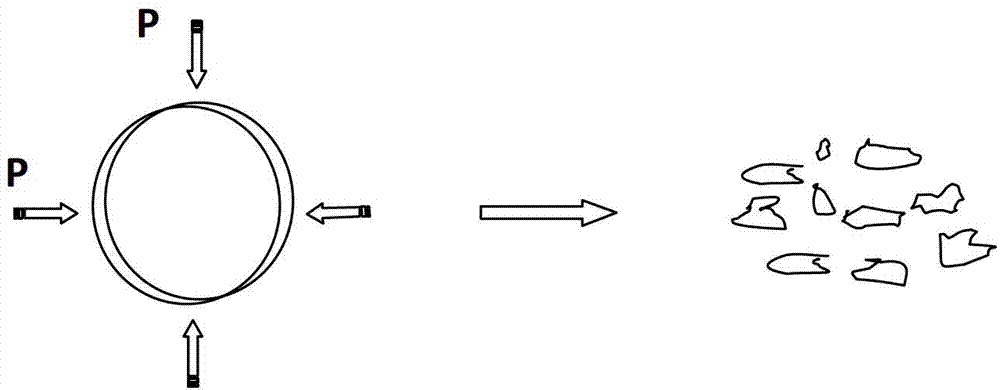

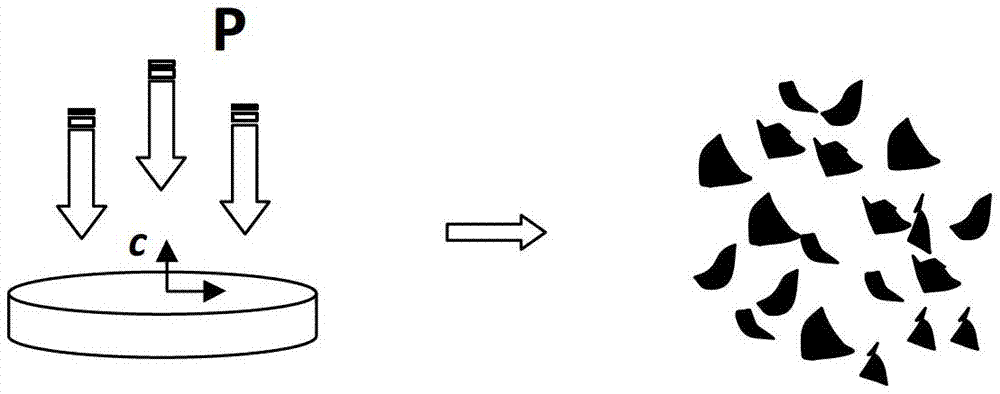

Method for preparing anisotropic NdFeB magnetic powder by directional crushing of thermally deformable magnets

An anisotropic, NdFeB technology, applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve problems such as damage to the main magnetic phase, transgranular fracture of magnets, limited application, etc., and achieve high residual magnetism. The effect of density, reduction of mechanical resistance, and improvement of degree of orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this example, the rapid quenching Nd 13.5 Fe 73 co 7.5 B 6 Magnetic powder is used as raw material to prepare anisotropic magnetic powder, and the process steps are as follows:

[0034] (1) Fully dense isotropic Nd 13.5 Fe 73 co 7.5 B 6 Magnet Preparation

[0035] Quenched Nd 13.5 Fe 73 co 7.5 B 6 Weigh 20g of the magnetic powder, put it into a Φ30mm hard alloy mold, apply a pressure of 4MPa at room temperature for compaction, and then put it into a vacuum induction hot press, and conduct induction hot pressing at 700°C under vacuum conditions (6Pa). The pressure is 150MPa, and the holding time is 2 minutes. After the holding time is reached, it is cooled to room temperature with the furnace to obtain fully dense isotropic Nd 13.5 Fe 73 co 7.5 B 6 A magnet whose magnetic properties are: B r =0.9T,H ci =1018kA / m, (BH) m =130kJ / m 3 , ρ=7.73g / cm 3 ;

[0036] (2) Thermal deformation anisotropy Nd 13.5 Fe 73 co 7.5 B 6 Magnet Preparation

[0037]...

Embodiment 2

[0073] In this example, the rapid quenching Nd 13.5 Fe 73 co 7.5 B 6 Magnetic powder is used as raw material to prepare anisotropic magnetic powder, and the process steps are as follows:

[0074] (1) Fully dense isotropic Nd 13.5 Fe 73 co 7.5 B 6 Magnet Preparation

[0075] Quenched Nd 13.5 Fe 73 co 7.5 B 6 Weigh 20g of the magnetic powder, put it into a Φ30mm hard alloy mold, apply a pressure of 4MPa at room temperature for compaction, and then put it into a vacuum induction hot press, and conduct induction hot pressing at 720°C under vacuum conditions (6Pa). The pressure is 150MPa, and the holding time is 4 minutes. After the holding time is reached, it is cooled to room temperature with the furnace to obtain fully dense isotropic Nd 13.5 Fe 73 co 7.5 B 6 A magnet whose magnetic properties are: B r =0.91T,H ci =1028kA / m, (BH) m =128kJ / m 3 , ρ=7.72g / cm 3 ;

[0076] (2) Thermal deformation anisotropy Nd 13.5 Fe 73 co 7.5 B 6 Magnet Preparation

[0077...

Embodiment 3

[0113] In this example, the rapid quenching Nd 13.5 Fe 80.4 Ga 0. 5B 5.6 Magnetic powder is used as raw material to prepare anisotropic magnetic powder, and the process steps are as follows:

[0114] (1) Fully dense isotropic Nd 13.5 Fe 80.4 Ga 0.5 B 5.6 Magnet Preparation

[0115] Quenched Nd 13.5 Fe 80.4 Ga 0.5 B 5.6 Weigh 20g of the magnetic powder, put it into a Φ30mm hard alloy mold, apply a pressure of 4MPa at room temperature for compaction, and then put it into a vacuum induction hot press, and conduct induction hot pressing at 700°C under vacuum conditions (6Pa). The pressure is 100MPa, and the holding time is 2 minutes. After the holding time is reached, it is cooled to room temperature with the furnace to obtain fully dense isotropic Nd 13.5 Fe 80.4 Ga 0.5 B 5.6 A magnet whose magnetic properties are: B r =0.79T,H ci =1647kA / m, (BH) m =102kJ / m 3 , ρ=7.60g / cm 3 ;

[0116] (2) Thermal deformation anisotropy Nd 13.5 Fe 80.4 Ga 0.5 B 5.6 Magnet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| magnetism | aaaaa | aaaaa |

| magnetism | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com