Preparation of peanut-oil-based plastic fat

A plastic fat and peanut oil technology, which is applied in the production/processing of edible oil/fat, can solve the problems of not being easy to restore to its original shape, and achieve the effects of good flavor, mild preparation conditions, and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take a certain amount of peanut oil in a 100mL beaker, heat it to 80°C, add 10% molecularly distilled monoglyceride to it, use IKAMAG RT10 multi-point magnetic stirrer to stir until the molecularly distilled monoglyceride is completely dissolved, and then continue to stir for 15 minutes. The sample was placed at 20°C for 36 hours to obtain non-emulsified peanut oil-based plastic fat.

Embodiment 2

[0022] Weigh a certain amount of molecularly distilled monoglyceride and stearic acid, and the mass ratio of the two is 20:1 to prepare a mixture of molecularly distilled monoglyceride and stearic acid; prepare 0.05mol / L NaOH aqueous solution as the water phase of the emulsification system . Take 10.75g of peanut oil in a beaker, heat it to 80°C, add 1.67g of the mixture of molecularly distilled monoglyceride stearic acid into the peanut oil, stir until the mixture is completely dissolved in the peanut oil with IKAMAG RT10 multi-point magnetic stirrer, add 12.5 g of water phase, continue to heat and stir until milky white uniform plastic fat is formed, and place the sample at 20°C for 1 hour for later use to obtain emulsified peanut oil-based plastic fat.

Embodiment 3

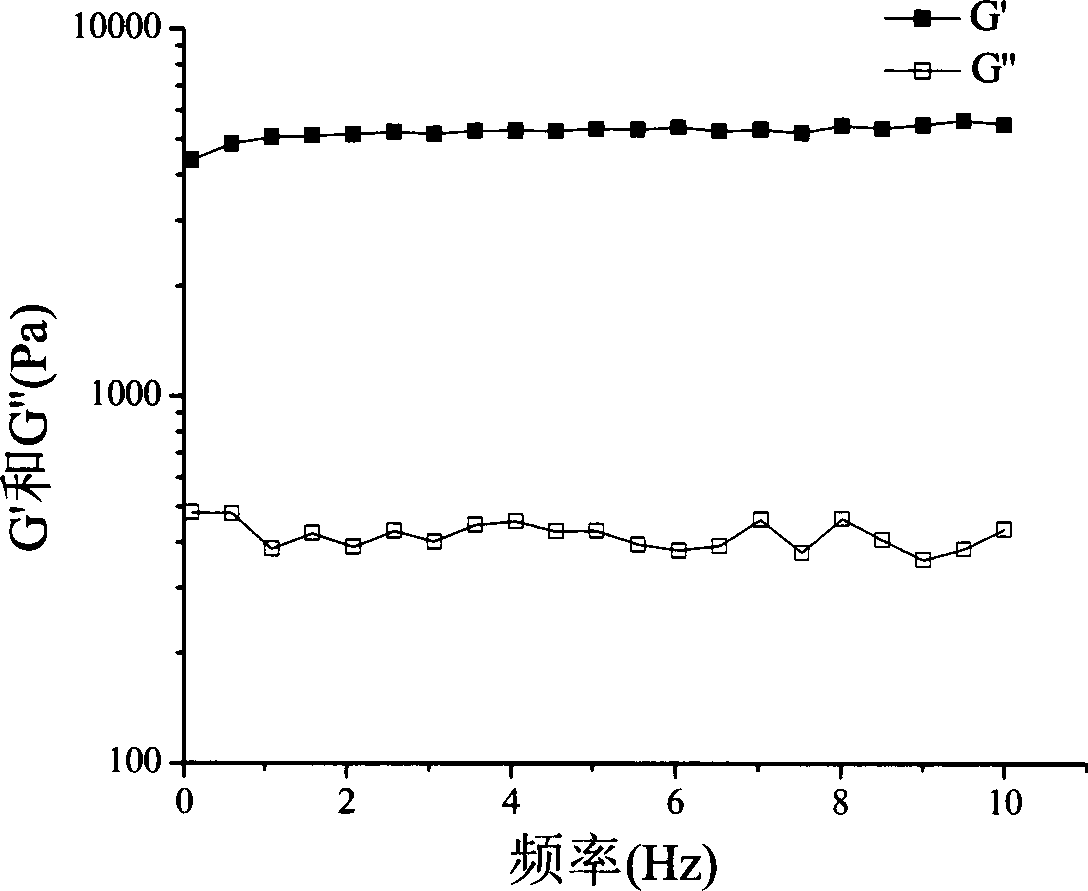

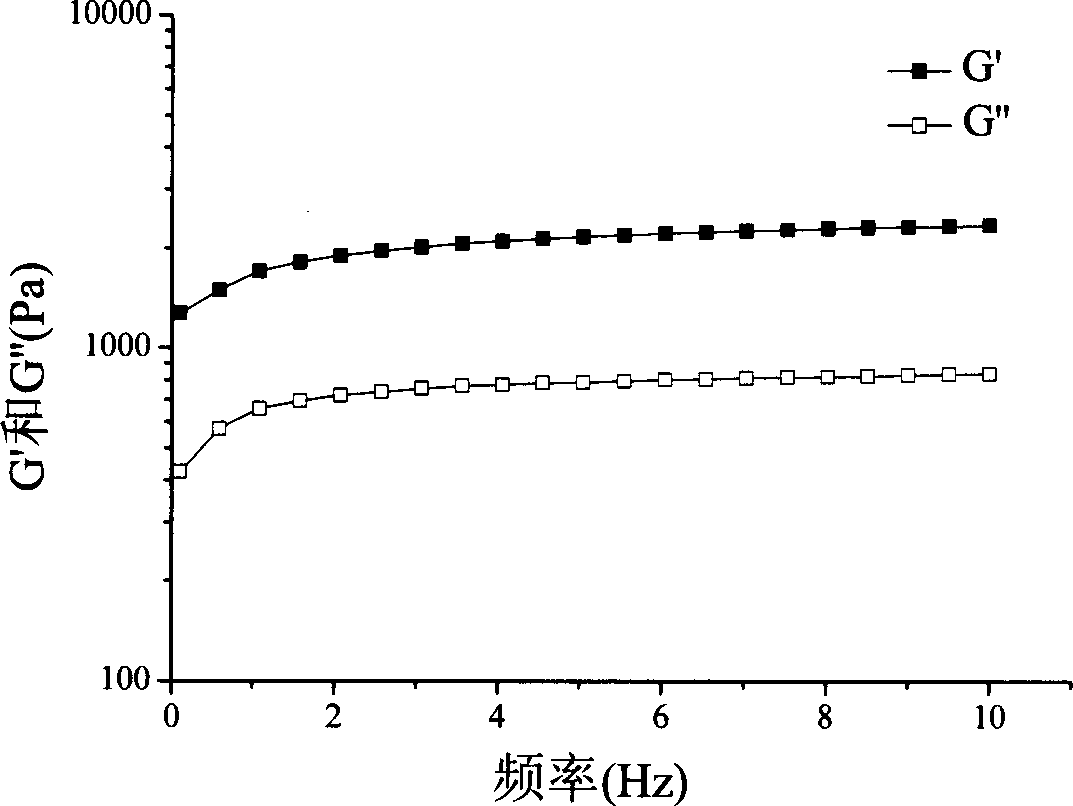

[0024] The storage modulus G′ and loss modulus G″ of the peanut oil-based plastic fat are measured using an AR-G2 rheometer with a diameter of 40mm and a 2° stainless steel cone plate. The static rheological properties are measured at 20°C, and the frequency scan range 0.1-10Hz.

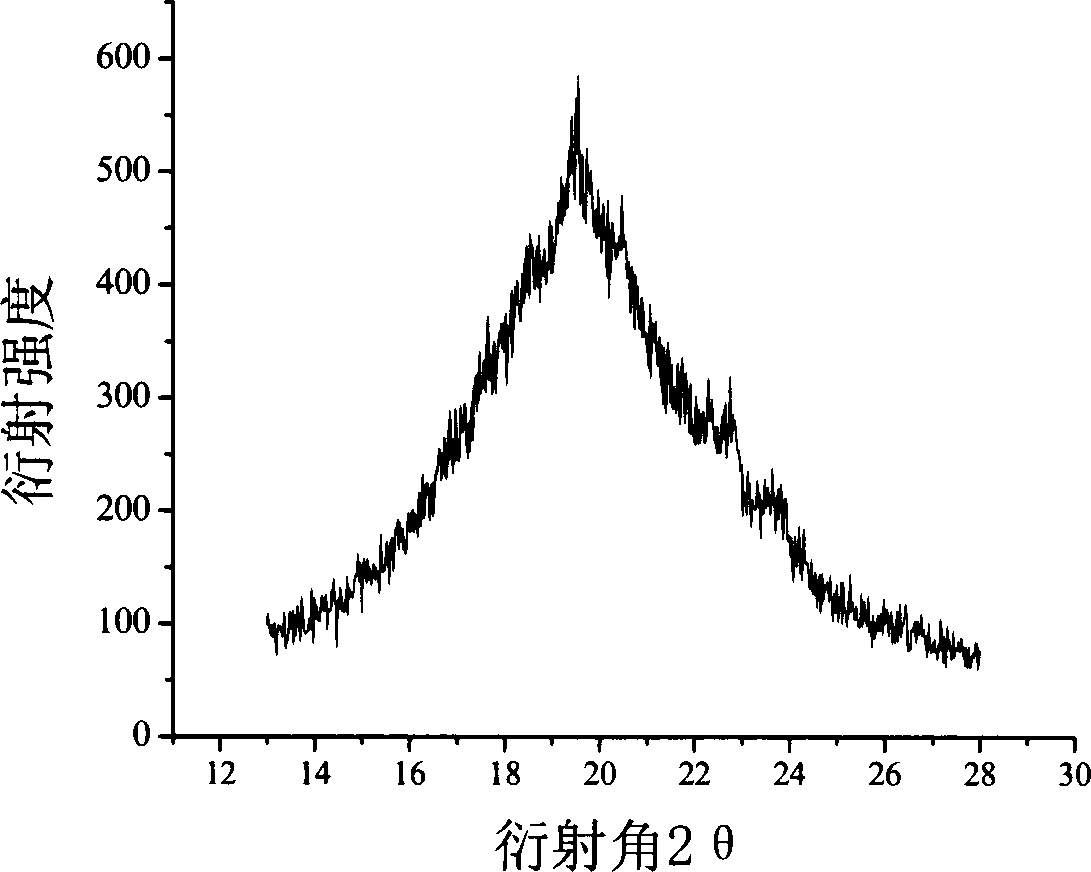

[0025] The crystal form analysis adopts the X-ray diffraction method, taking an appropriate amount of sample and spreading it in the circular hole on the test piece, and measuring it with an X-ray diffractometer. The condition is Cu target, the working voltage is 40kV, the current is 40mA, the emission and anti-reflection slit is 1.0mm, and the receiving slit is 0.1mm. min. from image 3 and Figure 4 It can be seen that the crystal form of the non-emulsifying system is mainly β-type, and the crystal form of the emulsifying system contains both β and α-type.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com