Difunctional light conversion master batches and preparation method thereof

A technology of bifunctional light-converting agent and light-converting masterbatch, which is applied in the fields of botanical equipment and methods, chemical instruments and methods, luminescent materials, etc., can solve the problems of little blue light, difficult light-converting agent, and inability to synchronize the life of the film. , to achieve the effect of good spectral matching, reducing dust pollution and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Synthesis of bifunctional light conversion agent Ca 0.7 Ba 0.3 f 2 :Eu

[0045] Weigh Ca(NO 3 ) 2 4H 2 O(14.8Kg), Ba(NO 3 ) 2 (5Kg), Eu 2 o 3 (17.00g), NH 4 F (11.5Kg), HNO 3 (25ml).

[0046] a. Use HNO first 3 Dissolved Eu 2 o 3 , adding Ca(NO 3 ) 2 4H 2 O and Ba(NO 3 ) 2 Prepare 0.25mol / L solution A;

[0047] Prepare 1mol / L NH 4 F solution B.

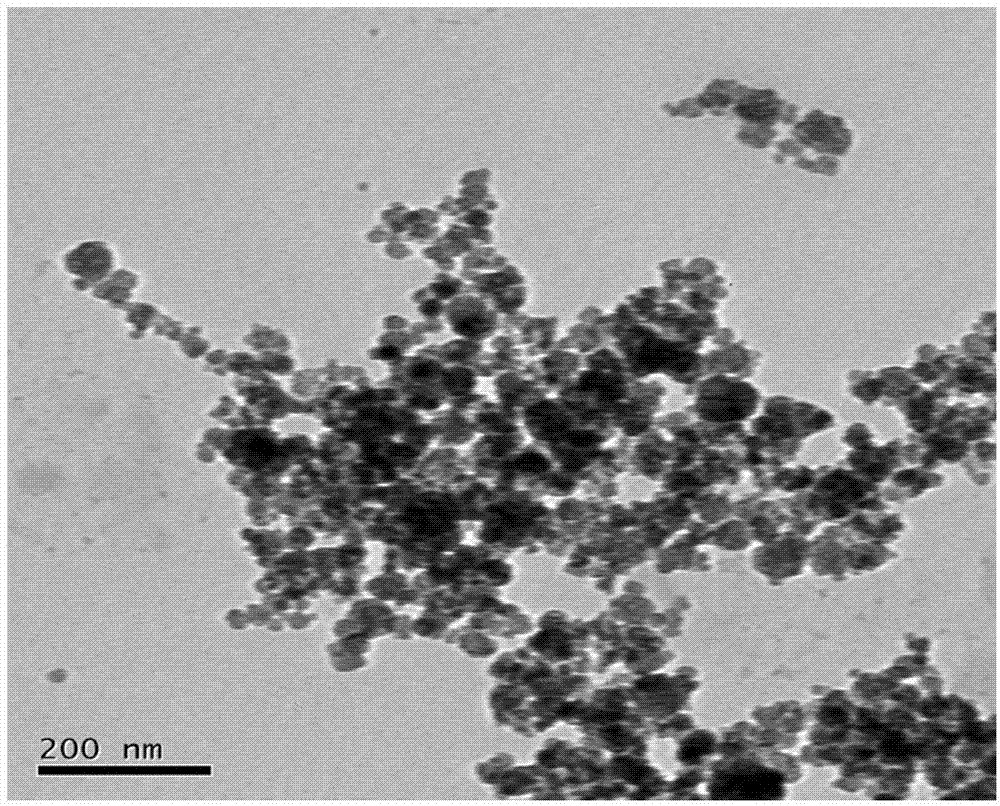

[0048] b. Under the condition of stirring, add solution A dropwise to solution B, continue stirring for 1 hour, centrifuge, and dry at 100°C. The SEM morphology of the precursor after drying is shown in the attached figure 1 As shown, its substance is a white lump.

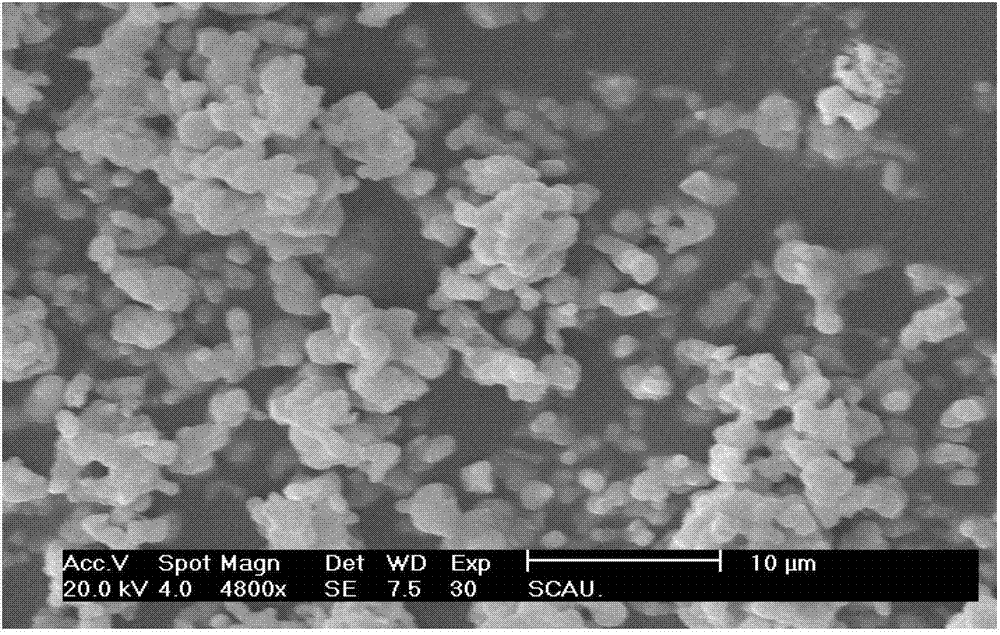

[0049] c. The above-mentioned precipitate after drying, after adding 0.5% of the flux CaF of the weight of the precipitate 2 Grinding, then calcination at 1200° C. for 2 hours under a CO reducing atmosphere, and gradually cooling to obtain a sample. The SEM morphology characteristics of the sample are as attached figure 2 As shown, t...

Embodiment 2

[0053] (1) Synthesis of bifunctional light conversion agent Ca 0.75 Zn 0.15 f 2 :Eu,Ce

[0054] Weigh Ca(NO 3 ) 2 4H 2 O(17.6Kg), Zn(NO 3 ) 2 、Ce 2 o 3 And MgO (total 3.2Kg), Eu 2 o 3 (17.00g), NH 4 F (11.5Kg), HNO 3 (25ml).

[0055] a. Use HNO first 3 Dissolved Eu 2 o 3 、Ce 2 o 3 and MgO, adding Ca(NO 3 ) 2 4H 2 O and Zn(NO 3 ) 2 Prepare 0.25mol / L solution A;

[0056] Prepare 1mol / L NH 4 F solution B.

[0057] b. Under the condition of stirring, add solution A dropwise to solution B, continue stirring for 1 hour, centrifuge, and dry at 100°C.

[0058] c. With the above-mentioned precipitate after drying, add 10% flux CaCl of the weight of the precipitate 2 Grinding, then calcination at 800° C. for 4 hours under a reducing atmosphere of nitrogen-hydrogen mixed gas, and gradually cooling to obtain a sample.

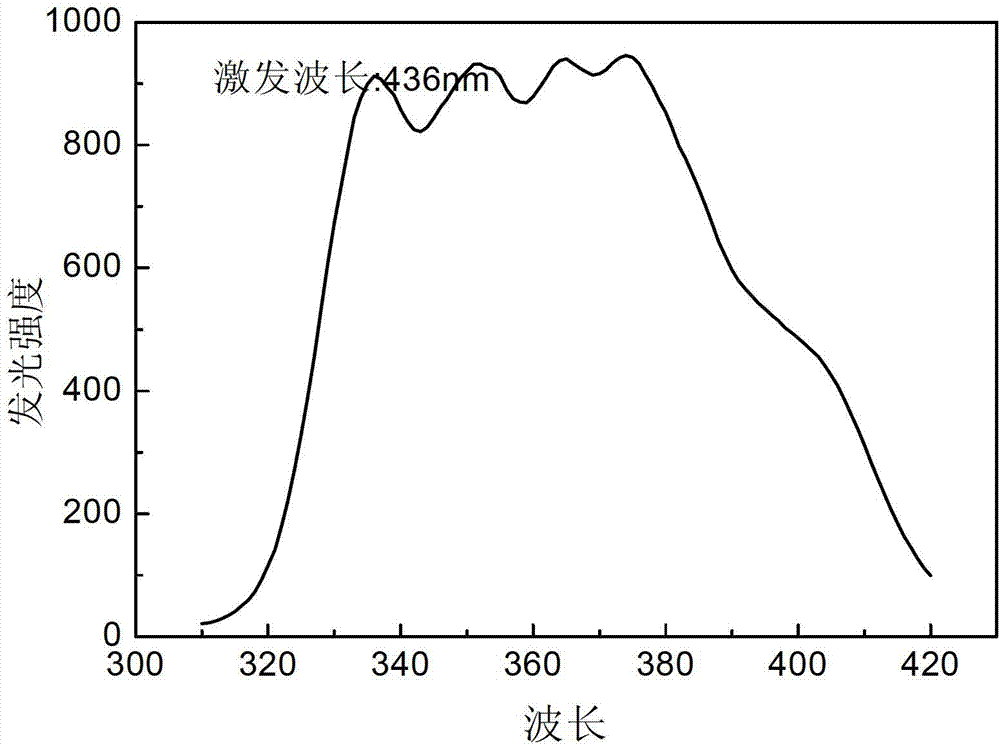

[0059] The excitation spectrum of the product in the ultraviolet region is attached image 3 As shown, the excitation spectrum in the green re...

Embodiment 3

[0063] (1) Synthesis of bifunctional light conversion agent Ca 0.65 Sr 0.30 Fe 0.05 f 2 :Eu

[0064] Weigh Ca(NO 3 ) 2 4H 2 O(24.5Kg), Sr(NO 3 ) 2 (11.2Kg), Fe 2 o 3 and Eu 2 o 3 (total 31.00g), NH 4 F (21.2Kg), HNO 3 (30ml).

[0065] a. Use HNO first 3 Dissolved Eu 2 o 3 , Fe 2 o 3 and Eu 2 o 3 , adding Ca(NO 3 ) 2 4H 2 O, Sr(NO 3 ) 2 (11.2Kg) prepare 0.25mol / L solution A;

[0066] Prepare 1mol / L NH 4 F solution B.

[0067] b. Under the condition of stirring, add solution A dropwise to solution B, continue stirring for 1 hour, centrifuge, and dry at 100°C.

[0068] c. the above-mentioned precipitate after drying, adding flux of 1% of the weight of the precipitate to carry out NaF grinding, then in H 2 with N 2 The mixture was calcined at 950° C. for 3 hours under a reducing atmosphere, and then cooled gradually to obtain a sample.

[0069] (2) Production of light conversion masterbatch

[0070]Weigh 10kg of sample 3 (1), polyvinyl chloride 30k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com