Method for preparing po huo glycoside I refined product

A technology of pure baojoside, which is applied in the field of preparing pure baojoside I, can solve the problems of large activity loss of baojoside I, severe hydrolysis environment, and low hydrolysis efficiency, and achieves rapid separation, simple operation process, The effect of increasing selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

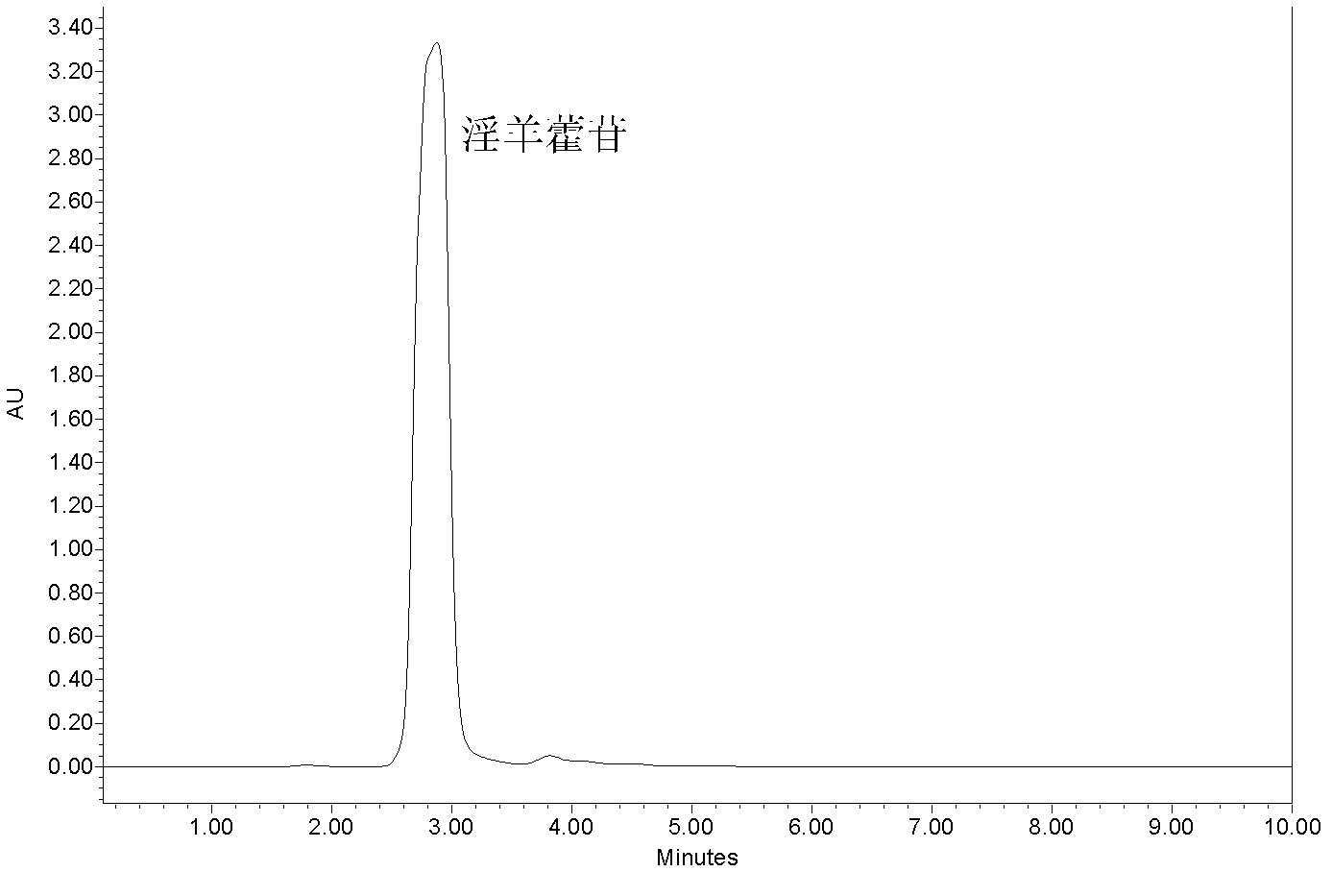

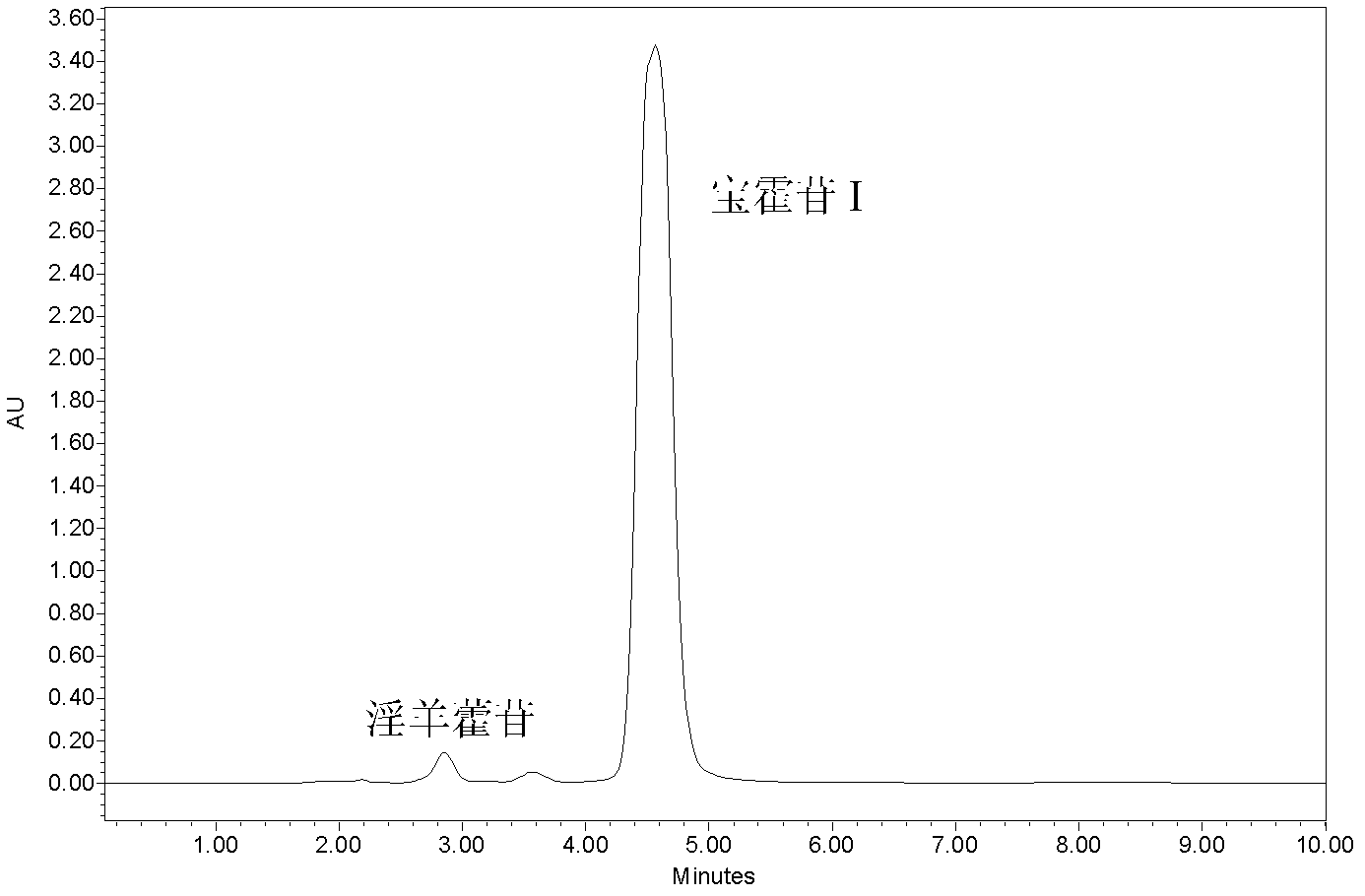

[0030] Take icariin 1mg ( figure 1 ), dissolved with citric acid buffer solution of 10ml pH 5.4, added 100ul of 5ug / ul enzyme mother solution, and hydrolyzed for 4 hours at 40 degrees Celsius; centrifuged to precipitate Baojoside I. The enzymatic hydrolysis product baojoside I precipitate was washed with water and centrifuged at 2000r / min for 5 minutes, the supernatant was discarded, and the process of washing, centrifuging and discarding the supernatant was repeated three times. Collect the precipitate, dissolve it with 3ml of cold methanol (-4 degrees Celsius), dissolve it with ultrasound, centrifuge at 2000r / min for 5 minutes, collect the supernatant, dissolve the solid with cold methanol again, dissolve it with ultrasound, centrifuge, and collect the supernatant, repeat three times in total , combined three supernatants to concentrate the obtained baojoside I crude product ( figure 2 ), the conversion rate can reach 98%.

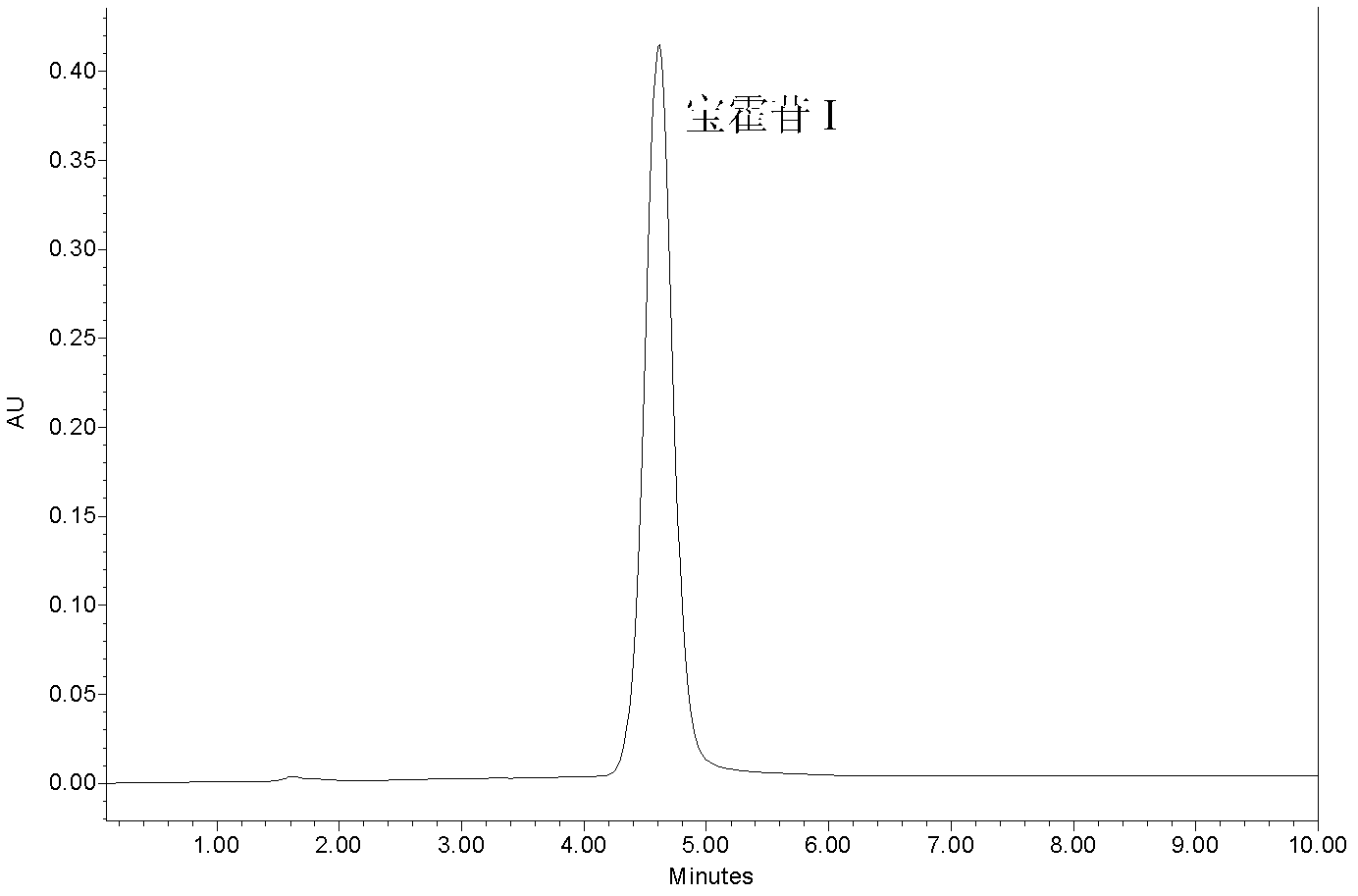

[0031] Baojoside was prepared by Waters 600E pr...

Embodiment 2

[0033] Take 5 mg of icariin, dissolve it in 15 ml of citric acid buffer solution with pH 7, add 500 ul of 5 ug / ul enzyme mother solution, and hydrolyze at room temperature (about 19 degrees Celsius) for 6 hours; centrifuge to precipitate baojoside I. The enzymatic hydrolysis product baojoside I precipitate was washed with water and centrifuged at 2000r / min for 5 minutes, the supernatant was discarded, and the process of washing, centrifuging and discarding the supernatant was repeated three times. Collect the precipitate, dissolve it with 5ml of cold methanol (4 degrees Celsius), dissolve it with ultrasound, centrifuge at 2000r / min for 5 minutes, collect the supernatant, dissolve the solid with cold methanol again, dissolve it with ultrasound, centrifuge, and collect the supernatant, repeat three times in total. The supernatants were combined and concentrated for three times to obtain the crude product of baojoside I, and the conversion rate could reach 97%.

[0034] Baojoside...

Embodiment 3

[0036] Take 25 mg of icariin, dissolve it in 100 ml of citric acid buffer solution with pH 4, add 1 ml of 5 ug / ul enzyme mother solution, and hydrolyze at 80 degrees Celsius for 3 hours; centrifuge to precipitate Baojoside I. The enzymatic hydrolysis product baojoside I precipitate was washed with water and centrifuged at 2000r / min for 5 minutes, the supernatant was discarded, and the process of washing, centrifuging and discarding the supernatant was repeated three times. Collect the precipitate, dissolve it with 8ml of cold methanol (-2 degrees Celsius), dissolve it with ultrasound, centrifuge at 2000r / min for 5 minutes, collect the supernatant, dissolve the solid with cold methanol again, dissolve it with ultrasound, centrifuge, and collect the supernatant, repeat three times in total , the supernatant was combined and concentrated for three times to obtain the crude product of baojoside I, and the conversion rate could reach 97.5%.

[0037] Baojoside was prepared by Waters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Column length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com