Synthetic method for simultaneously preparing positive electrode material and negative electrode material of high-performance supercapacitor by taking Co-MOF array as precursor

A technology for supercapacitors and negative electrodes, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, and can solve the problems of limited promotion and large-scale application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of synthetic method that uses Co-MOF array as precursor to simultaneously prepare positive and negative electrode materials of high-performance supercapacitor, comprises the following steps:

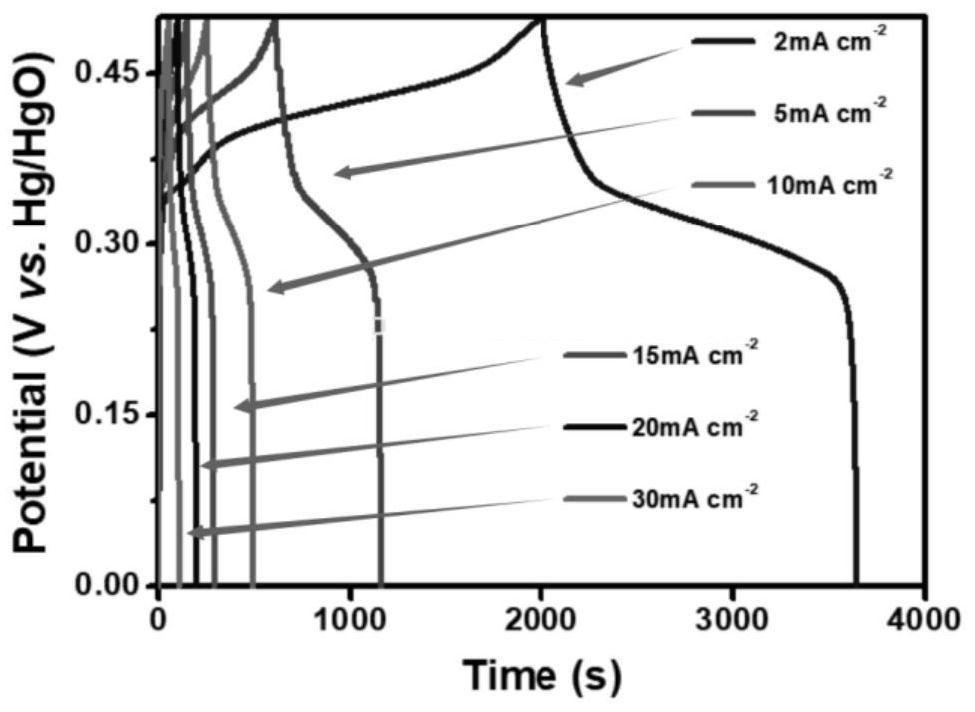

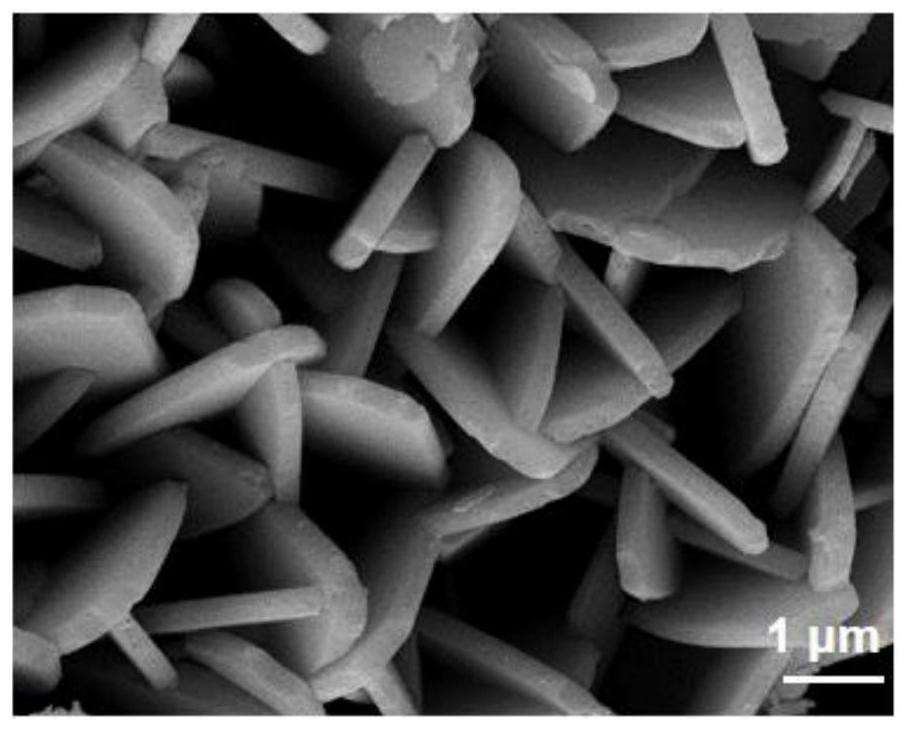

[0024] (1) Cobalt nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) and dimethylimidazole (2-MI) were dissolved in deionized water respectively, then the above two solutions were mixed, and a piece of 1*1cm foam nickel (NF) or foam iron nickel (FNF) was vertically immersed in the above solution , standing at room temperature for 2 h to obtain Co-MOF@NF grown on nickel foam current collector and Co-MOF@FNF grown on iron nickel foam current collector. The morphology of Co-MOF@NF is shown in its scanning electron microscope ( figure 1 ); the crystallinity of Co-MOF@NF is shown in its powder X-ray diffraction pattern ( figure 2 ); the morphology of Co-MOF@FNF is shown in its scanning electron microscope ( image 3 ); the crystallinity of Co-MOF@FNF is shown in its powder X-ray di...

Embodiment 2

[0029] A Synthetic Method for Simultaneous Preparation of High-performance Supercapacitor Positive and Negative Electrode Materials Using Co-MOF Arrays as Precursors

[0030] Include the following steps:

[0031] (1) The preparation of Co-MOF@NF and Co-MOF@FNF precursors is the same as in Example 1.

[0032] (2) The preparation of CN-LDH is the same as in Example 1, and this process does not need to carry out NaVO to CN-LDH 3 Etching treatment.

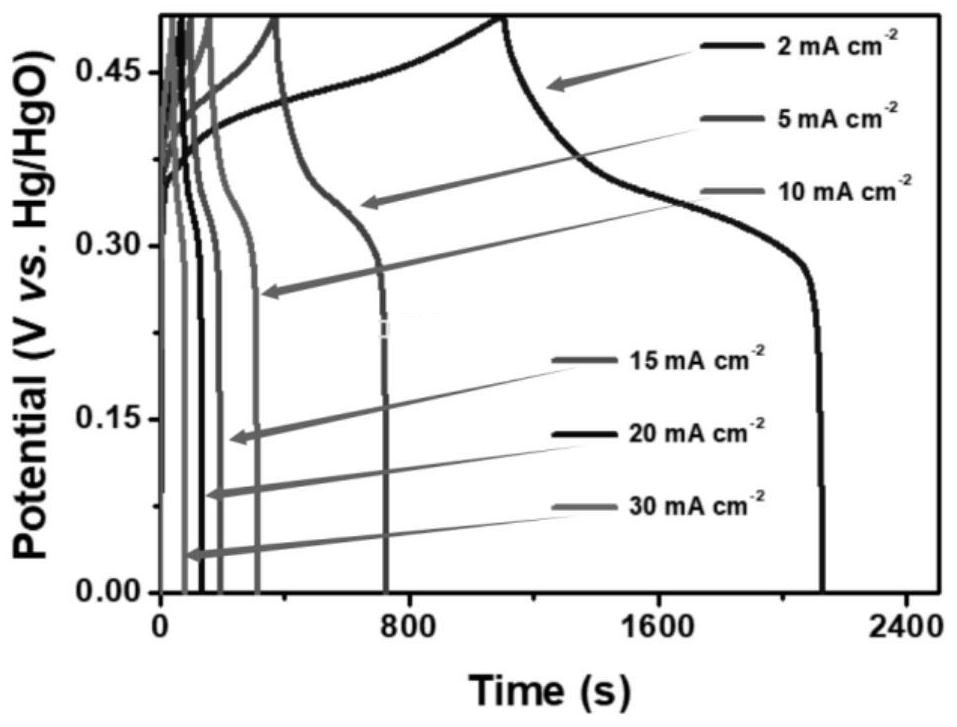

[0033] (3) The preparation of CFV is the same as in Example 1.

[0034] (4) Directly immerse the obtained CN-LDH vertically into a solution containing 7.5mg mL -1 In 3 mL of thioacetamide (TAA) solution, the CNS material was prepared by reacting at 160 °C for 12 hours. The constant current charge and discharge of CNS at different scan rates are as follows: Figure 20 As shown in the figure, the CNS is calculated at 2mA cm -2 The specific capacity at the current density reaches 3252mF cm -2 . The preparation of CFVS is the same...

Embodiment 3

[0036] A kind of synthetic method that uses Co-MOF array as precursor to simultaneously prepare positive and negative electrode materials of high-performance supercapacitor, comprises the following steps:

[0037] (1) The preparation of the Co-MOF precursor is the same as in Example 1.

[0038] (2) The preparation of CNV is the same as in Example 1.

[0039] (3) The preparation of CFV is the same as in Example 1.

[0040] (4) Vertically immerse the obtained CNV into a solution containing 2.5mg mL -1 In 3 mL of thioacetamide (TAA) solution, the reaction was carried out at 160°C for 12 hours. Obtain CNVS-1 material. The constant current charge and discharge of CNVS-1 at different scan rates are as follows: Figure 21 As shown in the figure, CNVS-1 is calculated at 2mA cm -2 The specific capacity at the current density reaches 4096mF cm -2 . The preparation of CFVS is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com