Titanium-based shift catalyst as well as preparation method and application thereof

A shift catalyst, titanium-based technology, applied in the field of titanium-based shift catalyst and its preparation, can solve the problems of anti-sulfurization, poor thermal stability, carrier phase change, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

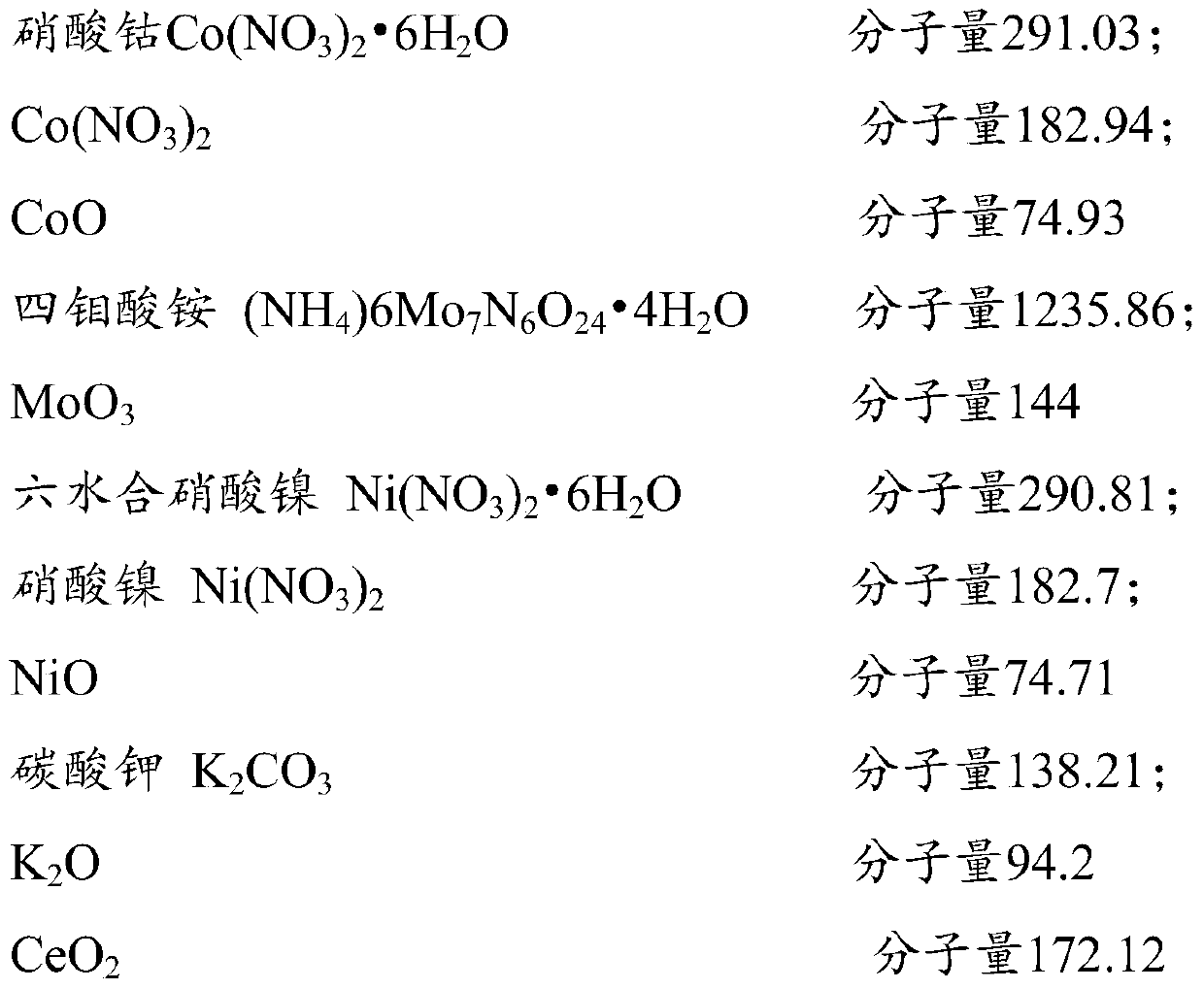

[0066] Weigh titanium silicon powder 102.44g (TiO 2 / SiO 2 =3:1 solid content 82%), hydroxypropyl methylcellulose (CMC) 1g, and cyanine powder 2.5g are put into the kneader, start the kneader and add a certain amount of deionized water, so that the material is kneaded until it can Extruded on extruder. Put the kneaded material into the extruder to extrude strips to obtain strips; put the strips into an electric oven for drying, the temperature is controlled at 80-120°C; the dried strips are broken and sieved , and put into a muffle furnace for co-calcination, the calcination temperature is 500 ℃, and the calcination time is 2 hours, to obtain the titanium silicon carrier. The titanium silica carrier has a hygroscopicity of 34%.

[0067] Weigh 3.88g of cobalt nitrate, 60.08g of ammonium molybdate, and 11.74g of potassium carbonate into a 250ml beaker, add deionized water to the 100ml scale, heat slightly on an electric furnace to 45-55°C to dissolve all the additions, and di...

Embodiment 2

[0072] Weigh and pulverize standby titanium silicon powder (TiO 2 / SiO 2 =3:1 solid content 82%) 105.12g, hydroxypropyl methylcellulose (CMC) 1g, methyl cyanine powder 2.5g, polyethylene oxide (PEO) 0.5g are put into the kneader, start the kneader and add A certain amount of deionized water is used to knead the material until it can be extruded on the extruder. Put the kneaded material into the extrusion machine to extrude strips to obtain strips; put the strips into an electric oven for drying, the temperature is controlled at 80-120°C; the dried strips are broken and sieved , and put into a muffle furnace for co-calcination, the calcination temperature is 500 ℃, and the calcination time is 2 hours, to obtain the titanium silicon carrier. The titanium silica support is 30% hygroscopic.

[0073] Weigh 3.11g of cobalt nitrate, 51.49g of ammonium molybdate, 4.89g of nickel nitrate, and 7.34g of potassium carbonate into a 250ml beaker, add deionized water to the 100ml scale, h...

Embodiment 3

[0079] Weigh titanium silicon powder (TiO 2 / SiO 2 =3:1 (solid content 82%) 103.41g, hydroxypropyl methylcellulose (CMC) 1g, methylene cyanine powder 2.5g, glycerin 0.5g put into the kneader, start the kneader and add a certain amount of deionized water , so that the material is kneaded until it can be extruded on the extruder. Put the kneaded material into the extrusion machine to extrude strips to obtain strips; put the strips into an electric oven for drying, the temperature is controlled at 80-120°C; the dried strips are broken and sieved , and put into a muffle furnace for co-calcination, the calcination temperature is 500 ℃, and the calcination time is 2 hours, to obtain the titanium silicon carrier. The titanium silica carrier has a hygroscopicity of 42%.

[0080] Weigh 4.66g of cobalt nitrate, 68.66g of ammonium molybdate, and 8.80g of potassium carbonate into a 250ml beaker, add deionized water to the 100ml mark, heat slightly on the electric furnace to 45-55°C to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com