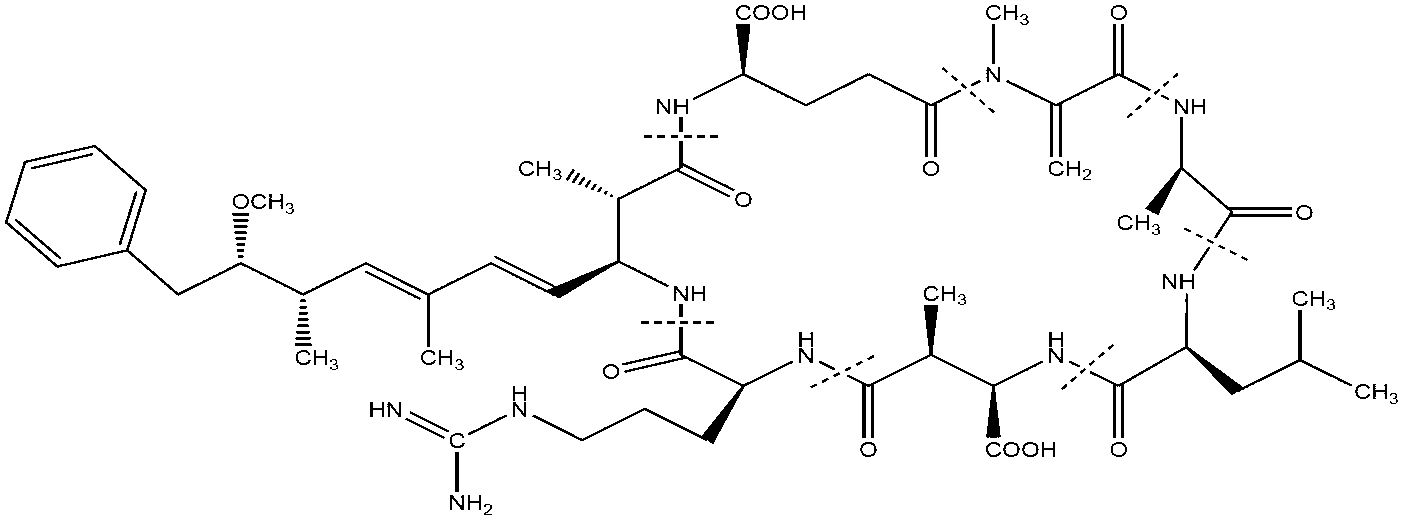

Method for extracting and purifying microcystic toxins LR and RR by taking cyanobacterial bloom in Dian Lake as raw material

A technology of microcystin and cyanobacteria water, applied in the field of analytical chemistry, can solve the problems of strong liver toxicity, inability to carry out large-scale production, and increase of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

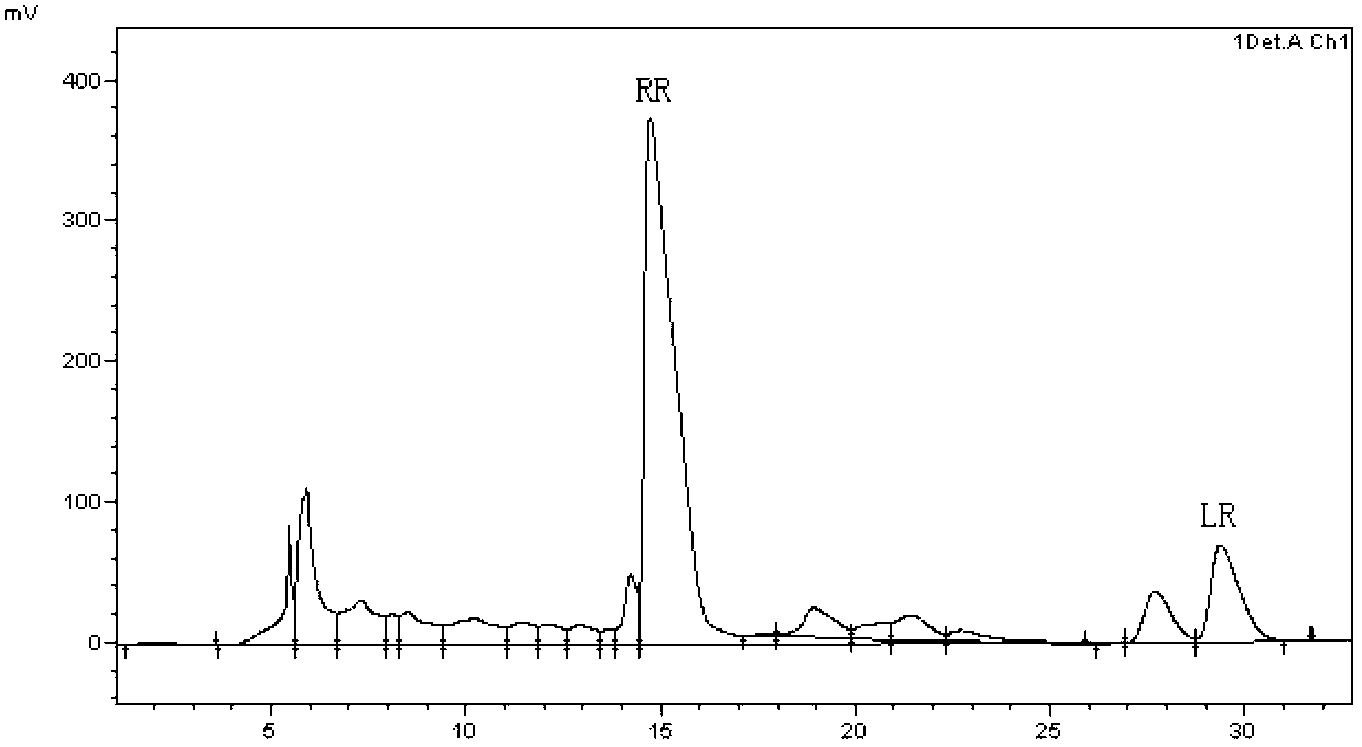

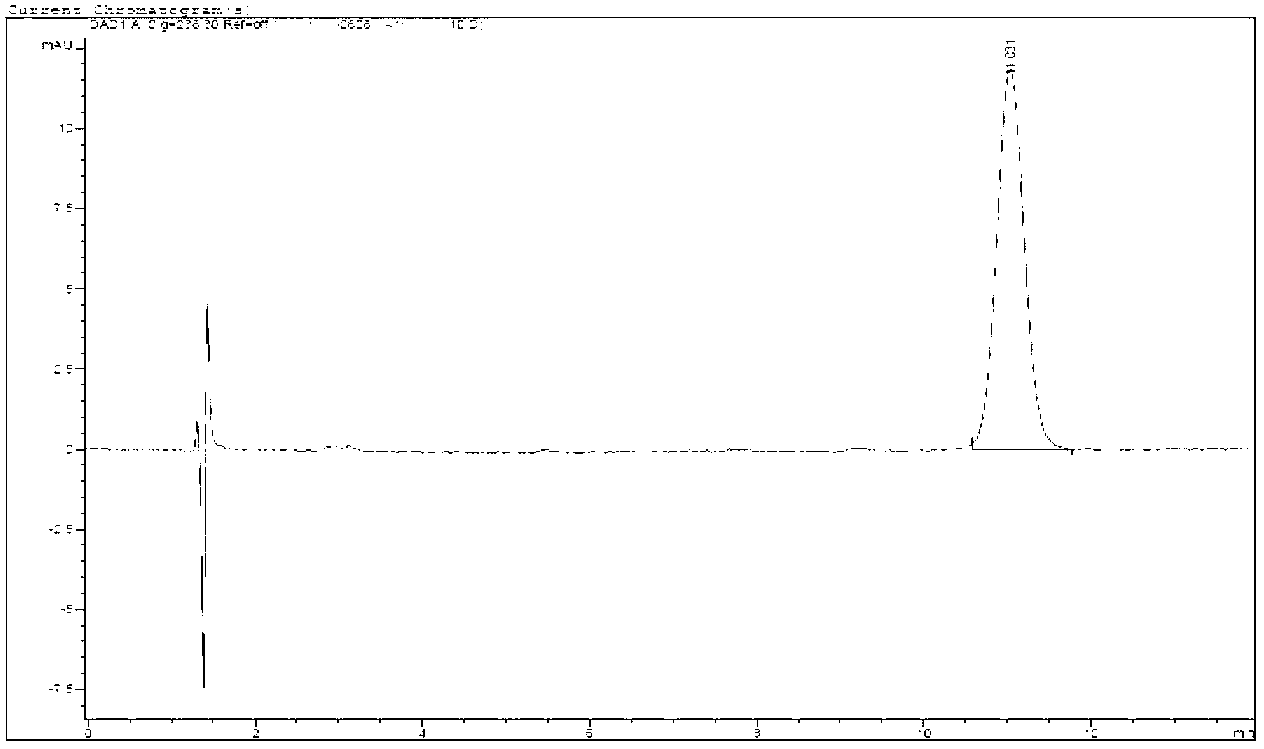

Examples

Embodiment 1

[0051] 1. Use No. 25 plankton net (pore size: 63 μm) to fish fresh algae samples from Dianchi Lake, filter the algae samples with a 60-mesh sieve (pore size: 230 μm) in the laboratory to remove larger groups and impurities; then use a 200-mesh sieve ( Pore size: 76μm) to remove smaller algae to increase the dominance of Microcystis in algal samples.

[0052] 2. Freeze and thaw the treated algae samples three times, and store them in a -20°C low-temperature refrigerator for later use.

[0053] 3. Use a vacuum freeze dryer to dehydrate the algal samples. Weigh about 80 grams of dry algae powder and soak it in 5L, 5% acetic acid solution, and shake it with an ultrasonic instrument. After soaking for 1 hour, centrifuge at a speed of 5000 rpm for 20 minutes, and take the supernatant.

[0054] 4. The supernatant was passed through the activated C18 solid-phase extraction column at a rate of 10 mL per minute to enrich the microcystins therein. The amount of cartridge used depends o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com