Method for preparing pregelatinized sweet potato powder by utilizing microwave

A technology of pregelatinization and sweet potato flour, which is applied in the field of microwave preparation of pregelatinization sweet potato flour, which can solve the problems of insufficient lubricity of taste and easy retrogradation and precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

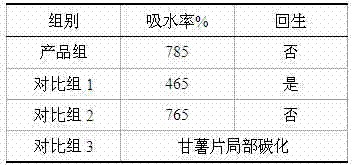

[0020] A method for preparing pre-gelatinized sweet potato powder by microwave The specific implementation steps are as follows: 1. Select 5 kg of fresh "Longshu No. 5" sweet potato and rinse it with clean water; 3. Place the sweet potato in a tunnel-type microwave device, microwave gelatinization for 3 minutes, and the microwave power is 50kw, which is equivalent to 10w / g of microwave power per unit mass; ④Put the sweet potato after microwave gelatinization in Carry out two-stage hot air drying treatment in the oven, the first stage temperature is 60°C, the time is 100 minutes, the second stage temperature is 80°C, and the time is 5 hours; ⑤ Grind the dried sweet potatoes to a fineness of 100 mesh , that is, the pregelatinized sweet potato flour is a product group. Contrast group: other process conditions remain unchanged, only the microwave power per unit mass is changed, 6w / g, 8w / g, 12w / g, recorded as comparison group 1, comparison group 2, and comparison group 3. Brew pre...

example 2

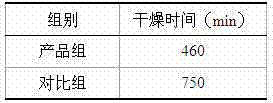

[0024] A method for preparing pregelatinized sweet potato flour with microwaves. The specific implementation steps are as follows: 1. Select 5 kg of fresh "Xinong 431" sweet potatoes and rinse them with clear water; 4mm dry potato chips; ③Put the sweet potato in a tunnel-type microwave device, microwave gelatinization for 6 minutes, and the microwave power is 40kw, which is equivalent to the microwave power per unit mass of 8w / g; ④Place the sweet potato after microwave gelatinization in an oven Carry out two-stage hot air drying treatment in the middle, the first stage temperature is 58 ℃, time is 100 minutes, the second stage temperature is 75 ℃, time is 6 hours; ⑤ the sweet potato after drying is pulverized, fineness is 100 mesh, The obtained pregelatinized sweet potato powder is a product group. Contrast group: other technological conditions are constant, and drying process is changed into common hot air drying, is recorded as contrast group, compares drying time, and resul...

example 3

[0028] A method for preparing pregelatinized sweet potato flour with microwaves. The specific implementation steps are as follows: 1. select 5 kg of fresh "Smoke Potato 25" sweet potatoes, and rinse them with clear water; 5mm dry potato chips; ③ put the sweet potato in the tunnel microwave device, microwave gelatinization for 5 minutes, the microwave power is 50kw, which is equivalent to the microwave power per unit mass of 10w / g; ④ put the microwave gelatinized sweet potato in the oven Carry out two-stage hot air drying treatment in the middle, the first stage temperature is 62 ℃, time is 80 minutes, the second stage temperature is 85 ℃, time is 6 hours; That is, pregelatinized sweet potato flour is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com