Visible light catalysis H2O2 synthesis catalyst as well as preparation method and application thereof

A technology of H2O2 and catalyst, applied in the field of visible light catalytic synthesis of H2O2 catalyst and its preparation, can solve the problems of high cost, complicated hydrogen peroxide equipment, easy deactivation of catalyst, etc., achieve easy operation, improve photocatalytic activity and activity stability, raw material cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

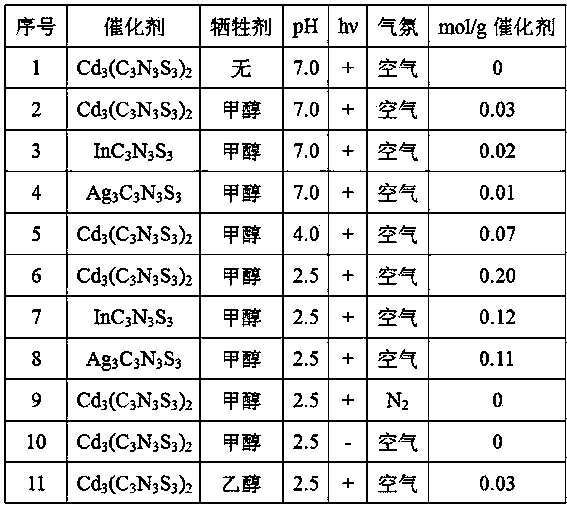

Embodiment 1

[0019] Take 1.5 mmol of cadmium nitrate, dissolve it in 200 ml of deionized water, and slowly drop the resulting solution into a solution of trisodium thiocyanate (1 mmol, 100 ml). After reacting for 24 hours, the obtained product was centrifuged, washed three times with deionized water, and dried in vacuum at 60°C for 24 hours to obtain the metal organic complex Cd 3 (C 3 N 3 S 3 ) 2 . Weigh 80 mg of the catalyst and directly disperse it in 20 ml of deionized water, and illuminate it with a light source ≥ 420 nm xenon lamp for 30 minutes in an air atmosphere.

Embodiment 2

[0021] Take 1.5 mmol of cadmium nitrate, dissolve it in 200 ml of deionized water, and slowly drop the resulting solution into a solution of trisodium thiocyanate (1 mmol, 100 ml). After reacting for 24 hours, the obtained product was centrifuged, washed three times with deionized water, and dried in vacuum at 60°C for 24 hours to obtain the metal organic complex Cd 3 (C 3 N 3 S 3 ) 2 . Weigh 80 mg of the catalyst and directly disperse it in 19 ml of deionized water containing 1 ml of methanol, and illuminate it with a light source ≥ 420 nm xenon lamp for 30 minutes in an air atmosphere.

Embodiment 3

[0023] Take 1 mmol of indium nitrate, dissolve it in 200 ml of deionized water, and slowly drop the resulting solution into the solution of trisodium thiocyanate (1 mmol, 100 mL). After reacting for 24 hours, the obtained product was centrifuged, washed three times with deionized water, and dried at 70°C for 24 hours in a nitrogen atmosphere to obtain the metal organic complex polymer InC 3 N 3 S 3 . Weigh 80 mg of the catalyst and directly disperse it in 19 ml of deionized water containing 1 ml of methanol, and illuminate it with a light source ≥ 420 nm xenon lamp for 30 minutes in an air atmosphere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com