A kind of high temperature resistant sand control proppant and high temperature resistant sand control solidification system

A technology of high temperature resistance and proppant, used in chemical instruments and methods, drilling compositions, etc., can solve the problems of low compressive strength and permeability of consolidated body, poor temperature resistance, complex production process, etc. Room temperature curing and high temperature resistance, good temperature resistance, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

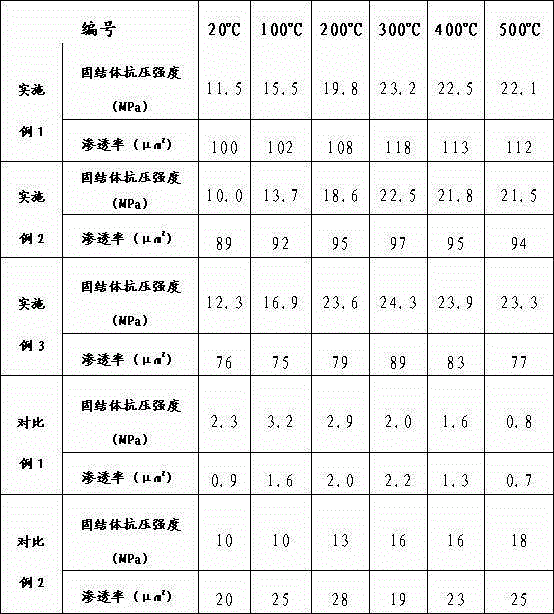

Examples

Embodiment 1

[0027] 1. Preparation of sand control proppant

[0028] Heat 2kg of quartz sand with a particle size of 0.425-0.85mm to 600 o After C, pour it into the sand mixer and stir to reduce the temperature to 180 o C, then add 50g of temperature-resistant thermosetting phenolic resin and 1g of toughening agent into the sand mixer, stir for 30s, initially coat the quartz sand, and then add 10g of liquid epoxy with an epoxy value of 0.23-0.56eq / 100g The resin was stirred for 30s, then 5g of dispersant was added and stirred for 15s, and sieved to obtain the high temperature resistant sand control proppant of the present invention. , phosphorus-modified phenolic resin, molybdenum-modified phenolic resin or a combination of several.

[0029] 2. Preparation of Curing Solution

[0030] Add 3g of imidazole curing agent into the beaker, then add 10ml of ethanol, stir evenly, add 0.1g of accelerator 2,4,6-tris(dimethylaminomethyl)phenol (DMP-30), continue stirring, and finally Dilute with w...

Embodiment 2

[0040] 1. Preparation of sand control proppant

[0041] Heat 50kg of ceramsite with a particle size of 0.3-1.18mm to 600 o After C, pour it into the sand mixer and stir to reduce the temperature to 180 oC, then add 70g of temperature-resistant thermosetting phenolic resin and 5g of toughening agent into the sand mixer, stir for 30s, initially coat the quartz sand, and then add 30g of liquid epoxy with an epoxy value of 0.23-0.56eq / 100g The resin was stirred for 30s, then 2.5g of dispersant was added and continued to stir for 15s, and sieved to obtain the high temperature resistant sand control proppant of the present invention. Resin, phosphorus modified phenolic resin mixed.

[0042] 2. Preparation of Curing Solution

[0043] Add a total of 5g of imidazole curing agent and polyamine curing agent into the beaker, then add 10ml of methanol, stir evenly and add 2g of accelerator phenol formaldehyde hexamethylenediamine condensate (701 # curing agent), continue to stir, and f...

Embodiment 3

[0053] 1. Preparation of sand control proppant

[0054] Heat 500g of a mixture of quartz sand and gravel with a particle size of 0.3-1.18mm to 600 o After C, pour it into the sand mixer and stir to reduce the temperature to 180 o C, then add 95g of temperature-resistant thermosetting phenolic resin and 0.1g of toughening agent into the sand mixer, stir for 30s, initially coat the quartz sand, and then add 5g of liquid ring with an epoxy value of 0.23-0.56eq / 100g The oxygen resin was stirred for 30 seconds, then 2.5 g of dispersant was added and continued to stir for 15 seconds, and sieved to obtain the high temperature resistant sand control proppant of the present invention. The temperature resistant thermosetting phenolic resin described in this example was a boron modified phenolic resin.

[0055] 2. Preparation of Curing Solution

[0056] Add 1g of polythiol curing agent to the beaker, then add 10ml of ethanol and methanol mixture, stir well, add 0.2g of accelerator phen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com