Method for modifying porous substrate and modified porous substrate

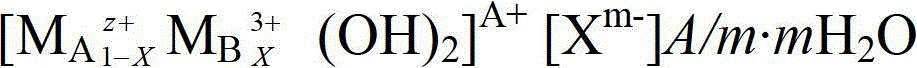

A technology for porous substrates and modification methods, applied in the field of modification methods and modified porous substrates, can solve the problems of reduced service life of palladium membranes, reduction of dense palladium membrane thickness, poor adhesion, etc., and achieve good adhesion properties, reducing film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The 316 porous stainless steel substrate (hereinafter referred to as 316PSS) was immersed in a + and Al 3+ the alkaline solution for one hour before drying. Contains Li + and Al 3+ The preparation method of the alkaline solution is to grind about 0.1-0.4 grams of AlLi intermetallic compound in a ceramic mortar into powder with a particle size of about 100-1000 μm. In this embodiment, the weight % of Li contained in the AlLi intermetallic compound relative to the total weight of the AlLi intermetallic compound is about 18-21%. Next, the AlLi intermetallic compound powder is placed in 100 mL of pure water, and an inert gas (for example, Ar or N) is introduced 2 ) and after aeration and stirring for several minutes, most of the AlLi intermetallic compound powder reacts with water and dissolves. Next, filter the impurities with filter paper with a pore size of 5A to obtain a clear and Li-containing + and Al 3+ alkaline solution. In this example, Li contains + and A...

Embodiment 2

[0036] The pores on the surface of 316PSS are filled with alumina particles, wherein the average particle size of the alumina particles is 10 μm. Next, by performing the LDH preparation method three times (as described in Example 1), a Li-AlLDH layer was obtained covering the surface of the 316PSS.

[0037]Next, the Li-AlLDH / 316PSS was calcined in a high-temperature furnace with a heating and cooling rate of 3°C / min and nitrogen gas flow. The process temperature was raised to 600°C and then kept at a constant temperature for 12 hours to remove the crystal water, carbonate and hydroxide of the LDH layer, so as to convert the Li-AlLDH layer into an aluminum oxide layer containing lithium. In this example, the obtained aluminum oxide layer Most of the layers have γ-phase, this test piece is referred to as γ-Al 2 O 3 / Al 2 O 3 / 316PSS.

[0038] Next, through the electroless plating preparation method (as described in Example 1), a sample of 316PSS with alumina particles in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com