Treatment method for waste water containing complex copper

A technology for complexing copper and wastewater, applied in water/sewage treatment, neutralized water/sewage treatment, multi-stage water/sewage treatment, etc., can solve the problem of increasing the possibility of hydrogen sulfide precipitation, unfavorable industrial production, and poor primary treatment effect and other problems, to achieve the effects of improving biodegradability, easy control of the treatment process, and reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0048] (1) Diversion and separate collection of wastewater

[0049] Wastewater treatment, especially the more complex wastewater in the circuit board industry, is basically classified and discharged on the production line, so that classified and diverted discharge provides a guarantee for subsequent treatment to meet standards. Therefore, the production line needs to divert and collect such wastewater separately, and the collection pool must have a certain buffer and homogenization function.

[0050] The treatment method provided by the present invention is mainly aimed at the treatment of EDTA-Cu and ammonia-copper mixed wastewater. The heavy metal copper in this type of wastewater exists in a complex state, and the purpose of removing copper pollutants can only be achieved after the complex is broken. , while other types of low-copper-containing wastewater can be separated separately, and heavy metals can be removed by simple alkali precipitation. The advantage of the above-...

Embodiment 1

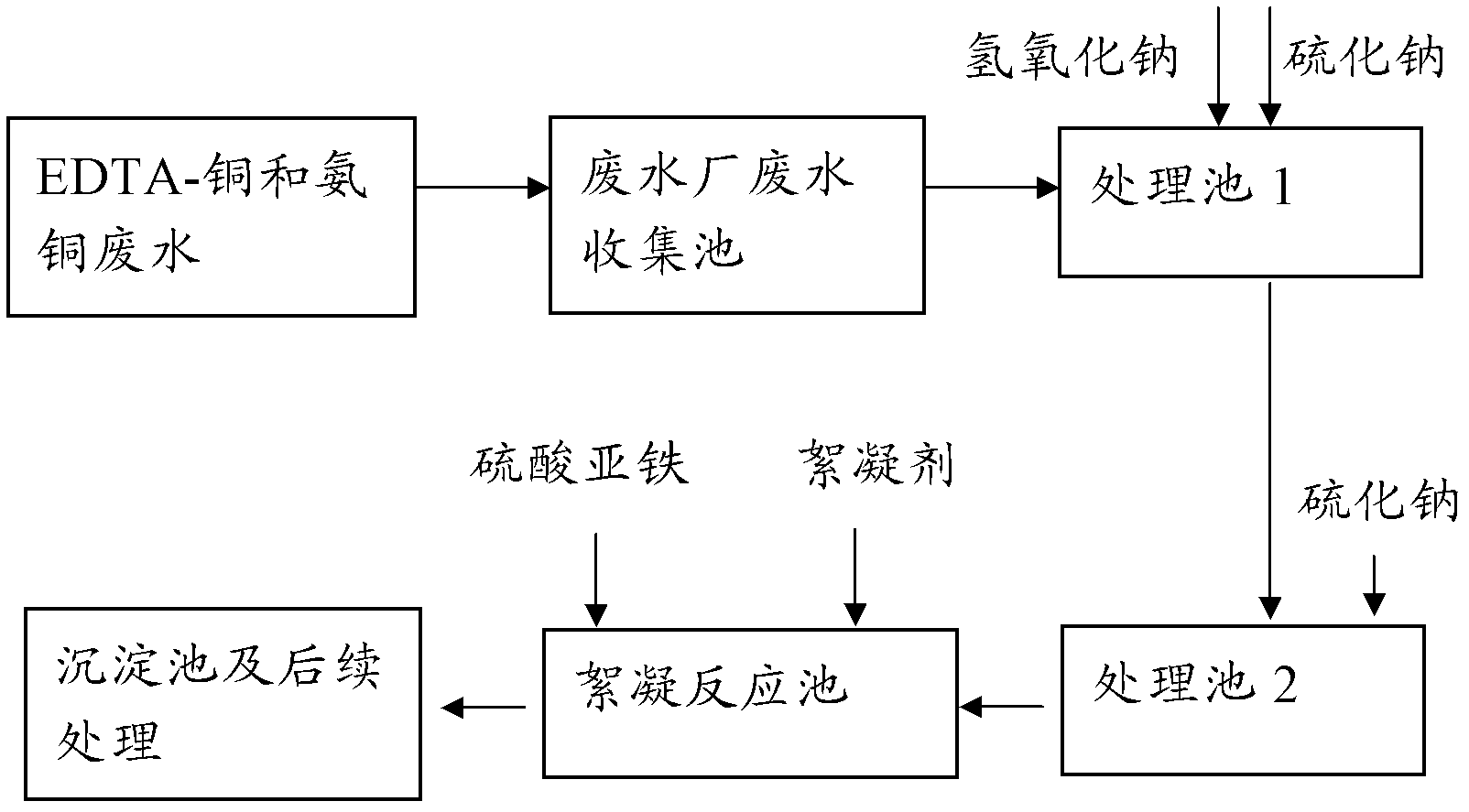

[0072] The EDTA-Cu wastewater discharged from the PTH line and the ammonia-copper wastewater discharged from the etching line are pumped at a distance of 50m 3 / h is continuously pumped into the treatment tank 1, and the mechanical stirring speed is 60rpm / min for continuous stirring. At this time, the copper content in the waste water is 60mg / l, and the COD is 200mg / l.

[0073] The control in the following operations adopts the Siemens PLC automatic control system, the model is ST-300. The pH is adjusted to 2 through automatic pH control, and 10% by weight of ferrous sulfate is added to the above-mentioned wastewater at 20 L / min at the same time, and the wastewater after fully reacting and breaking the network enters the treatment pool 2, and then the hydrogen is released through the automatic pH control. Sodium oxide is added to the waste water to adjust the pH of the waste water, the pH is controlled at 8.5, and the stirring speed is 60 rpm / min. The wastewater after adjusti...

Embodiment 2

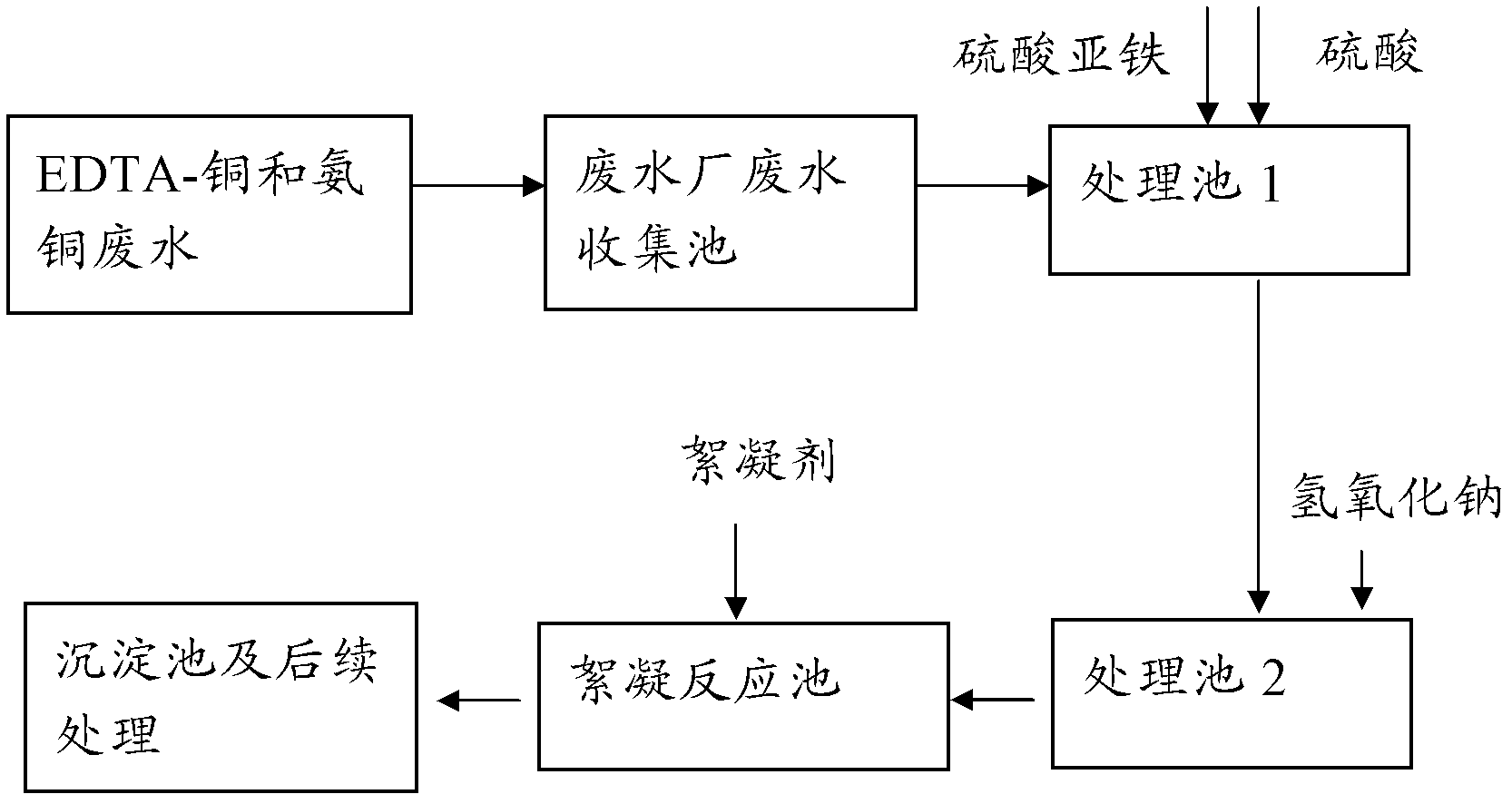

[0078] The EDTA-Cu wastewater discharged from the PTH line and the ammonia-copper wastewater discharged from the etching line are pumped at a distance of 30m 3 / h is continuously pumped into the treatment tank 1, and the mechanical stirring speed is 60rpm / min for continuous stirring. At this time, the copper content in the waste water is 60mg / l, and the COD is 200mg / l.

[0079] The control in the following operations adopts the Siemens PLC automatic control system, the model is ST-300. The pH is adjusted to 3 by automatic pH control, and 10% by weight of ferrous sulfate is added to the above-mentioned wastewater at 10L / min at the same time, and the wastewater after fully reacting and breaking the network enters the treatment pool 2, and then the hydrogen is released by automatic pH control. Sodium oxide is added to the wastewater to adjust the pH of the wastewater, the pH is controlled at 9.5, and the stirring speed is 60 rpm / min. The wastewater after adjusting the alkalinity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com