Thin film transistor array substrate, method for manufacturing the same, and annealing oven for performing the same method

A technology for thin film transistors and array substrates, applied in the field of thin film transistor array substrates, can solve problems such as burning, inability of an organic protective layer to withstand high temperatures, and oxidation phenomena.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following will clearly illustrate the spirit of the present invention with the accompanying drawings and detailed descriptions. After those skilled in the art understand the embodiments of the present invention, they can be changed and modified by the techniques taught in the present invention without departing from the present invention. spirit and scope.

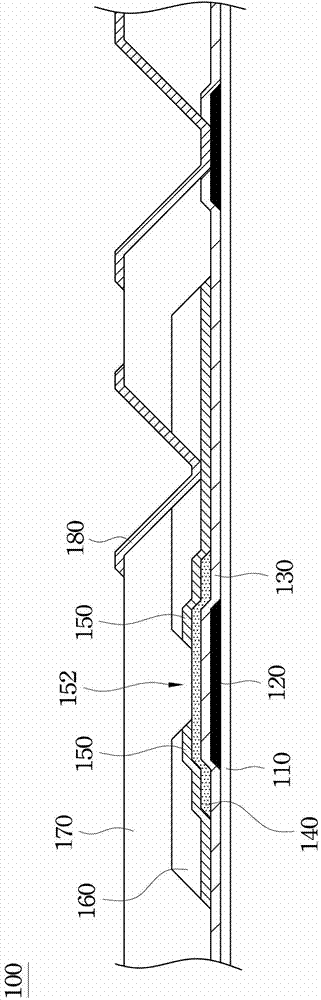

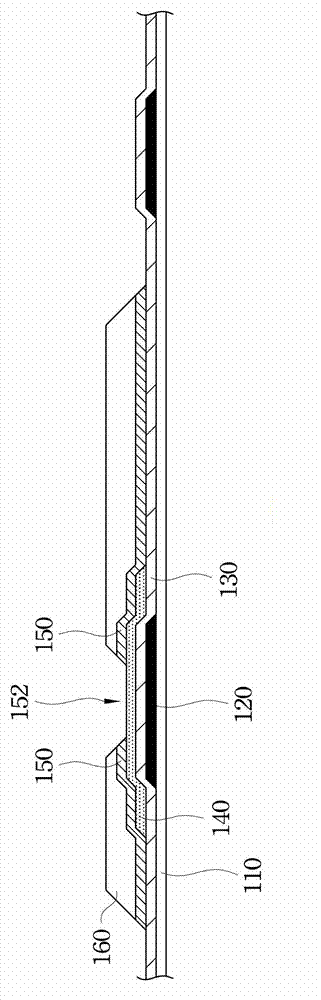

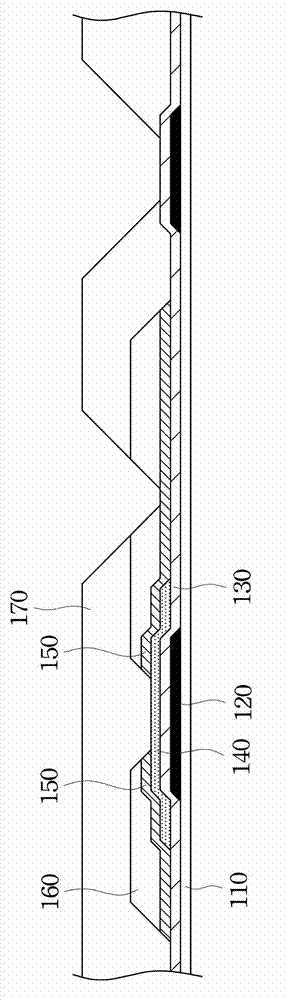

[0048] see figure 1 , which shows a schematic cross-sectional view of the thin film transistor array substrate 100 according to an embodiment of the present invention. Such as figure 1 As shown, the thin film transistor array substrate 100 includes a substrate 110, a gate layer 120, an insulating layer 130, an oxide semiconductor layer 140, a source / drain layer 150, an organic acrylic photoresist 160, a protective layer 170 and a conductive layer. 180.

[0049] The gate layer 120 is formed on the substrate 110 . In this embodiment, the substrate 110 may be a resin substrate, an organic polymer substrate or a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com