Preparation method of polymer micro-filtration membrane

A microfiltration membrane and polymer technology, applied in the field of membrane separation, can solve the problems of uncontrollable pore size and pore density of microfiltration membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of polymer microfiltration membrane, comprises the following steps:

[0030] A) Under the action of an initiator, a sulfonic acid monomer containing a double bond undergoes a polymerization reaction in an organic solution containing polyarylether sulfone ketone to obtain the first reaction mixture; the polyarylether sulfone ketone is dinitrogen-containing Polyaryl ether sulfone ketones of xinhones;

[0031] B) raising the temperature of the first reaction mixture to undergo a crosslinking reaction to obtain a second reaction mixture;

[0032] C) performing membrane-forming treatment on the second reaction mixture to obtain a polymer microfiltration membrane.

[0033] The present invention uses sulfonic acid monomers containing double bonds, phthalazinone-containing polyaryl ether sulfone ketones, and initiators as raw materials to undergo polymerization reactions in organic solvents to obtain the first reaction mixtur...

Embodiment 1

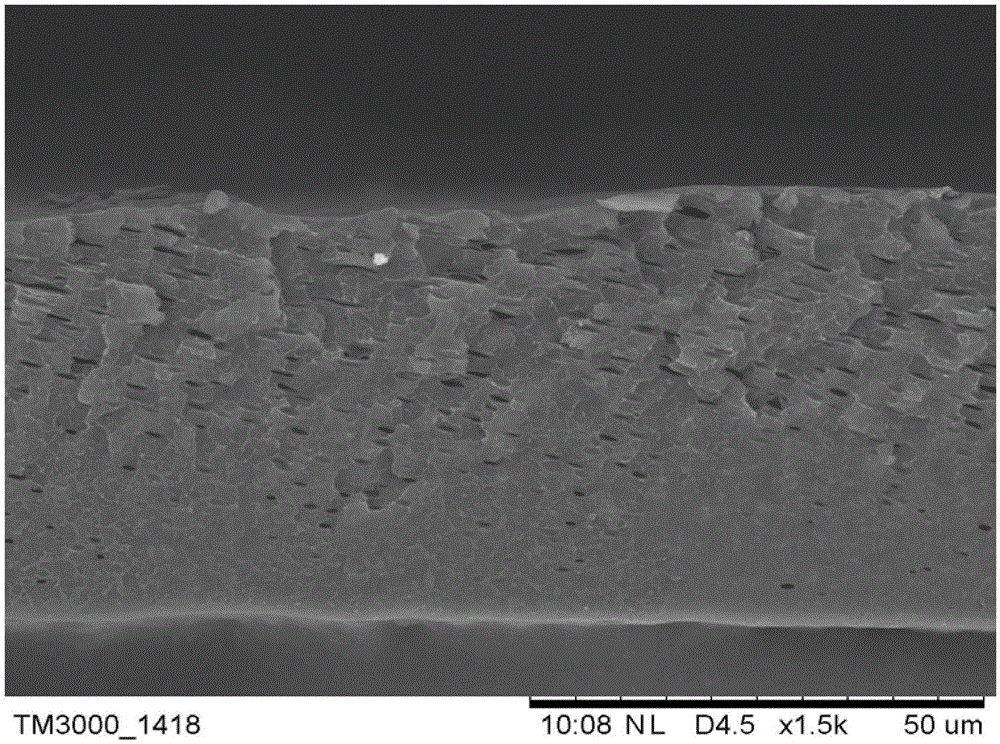

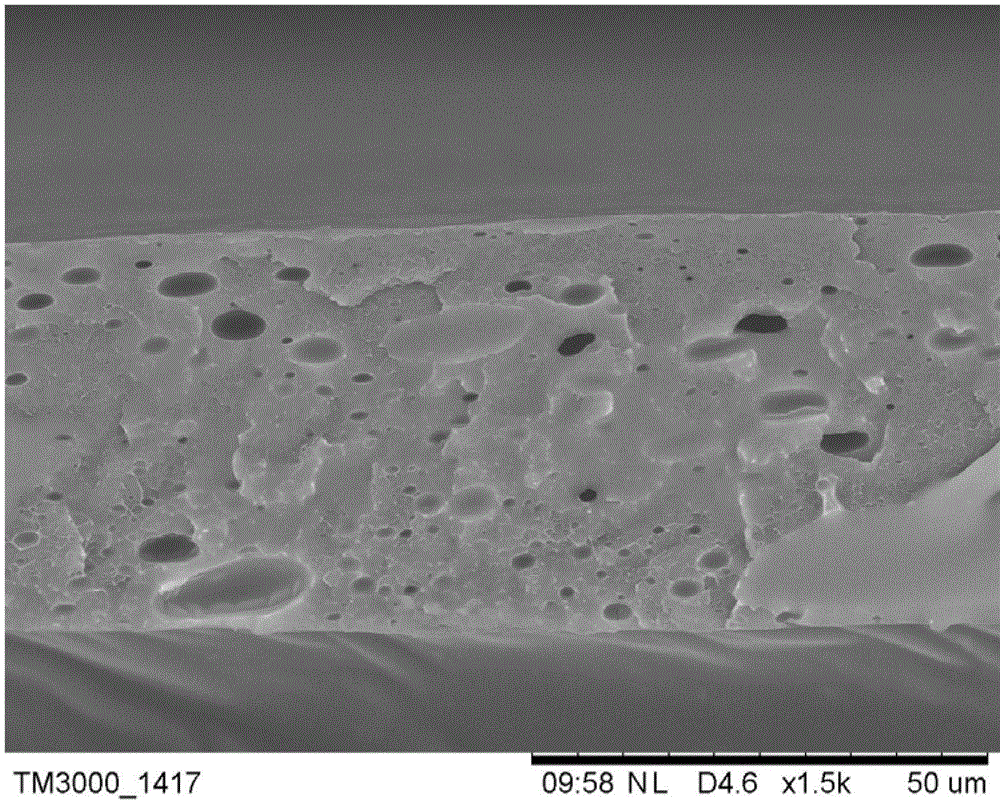

[0054] Put 15.06g of 1-methyl-2-pyrrolidone (NMP) into a three-necked flask, and then add 1.0mmol of styrenesulfonic acid (SSH) and 10.0mmol of polyarylethersulfoneketone (PPESK) containing phthalazinone until completely dissolved to obtain a prepolymer solution. Then add 0.011g of azobisisobutyronitrile (AIBN) to the above-mentioned pre-polymerization solution, stir and heat under the protection of nitrogen, and carry out the polymerization reaction under the condition of constant temperature and stirring at 80°C. After 4 hours, the first Reaction mixture, and then raise the temperature of the first reaction mixture and keep other reaction conditions unchanged, carry out the cross-linking reaction at a constant temperature of 120° C., and obtain the second reaction mixture after 2 hours. Put the above-mentioned second reaction mixture in a sealed reagent bottle and let it stand for 10 hours to remove air bubbles. Finally, cast the film naturally on a smooth and clean glass pl...

Embodiment 2

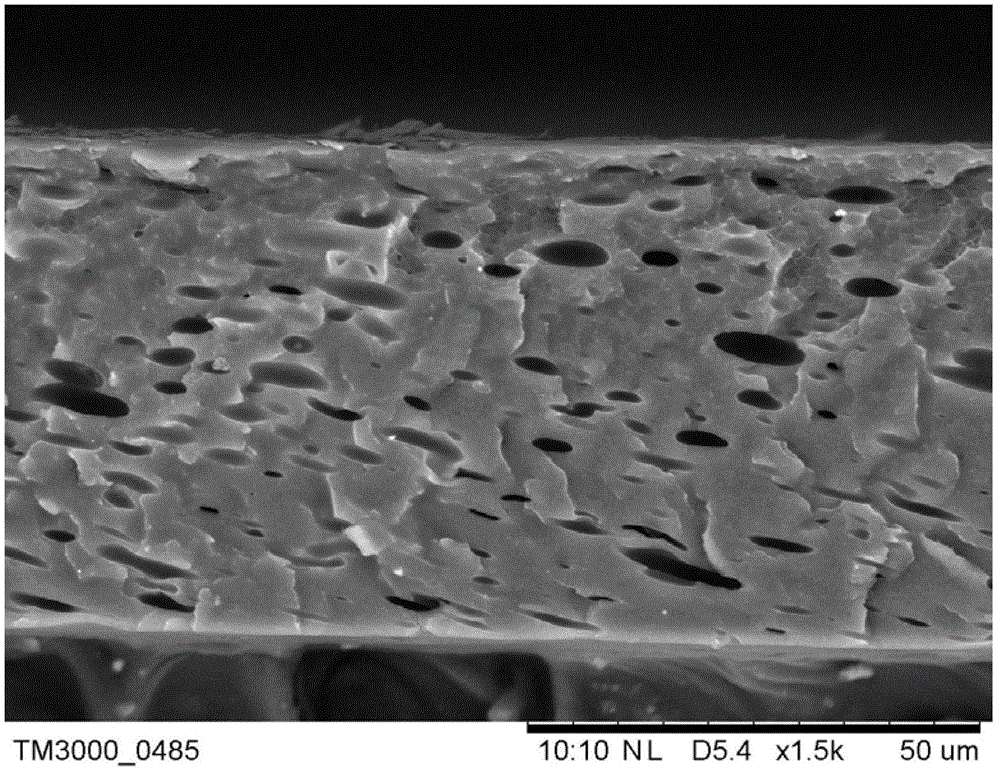

[0058] Put 26.18g of 1-methyl-2-pyrrolidone (NMP) into a three-necked flask, and then add 3.0mmol styrenesulfonic acid (SSH), 1.5mmol sodium styrenesulfonate (SSS), and 10.5mmol diazepine The polyarylether sulfone ketone (PPESK) of naphthone is completely dissolved to obtain the prepolymer liquid. Then add 0.009g of azobisisobutyronitrile (AIBN) to the above-mentioned pre-polymerization solution, stir and heat under the protection of nitrogen, and carry out the polymerization reaction under the condition of constant temperature and stirring at 70°C. After 5 hours, the first Reaction mixture, and then raise the temperature of the first reaction mixture and keep other reaction conditions unchanged, carry out the crosslinking reaction at a constant temperature of 130° C., and obtain the second reaction mixture after 3 hours. Put the above-mentioned second reaction mixture in a sealed reagent bottle and let it stand for 10 hours to remove air bubbles. Finally, cast the film natura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com