Die casting machining process and cutting system

A technology of processing technology and cutting system, which is applied in the direction of metal processing equipment, manufacturing tools, abrasive jet machine tools, etc., and can solve problems such as poor cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

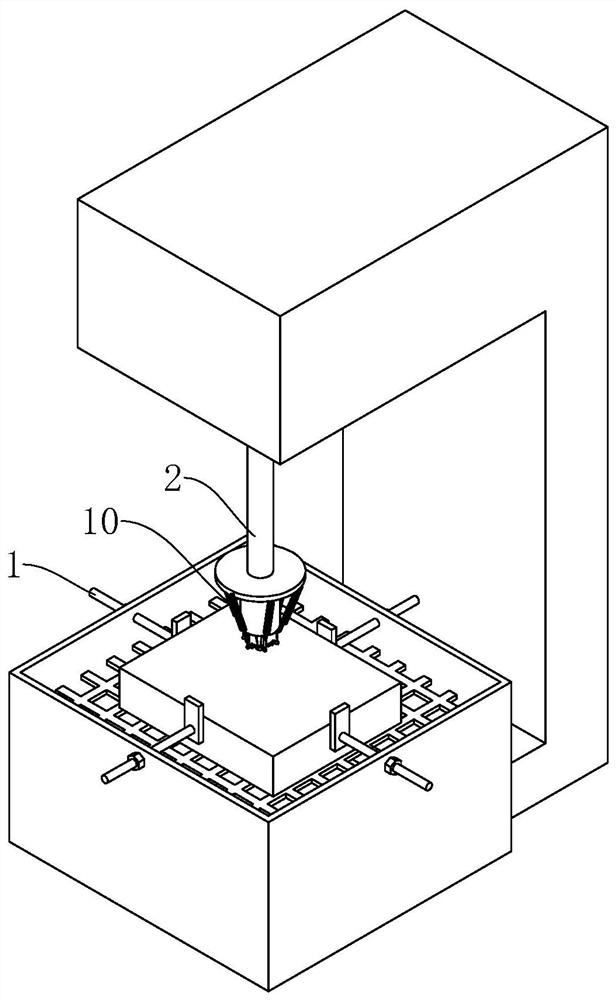

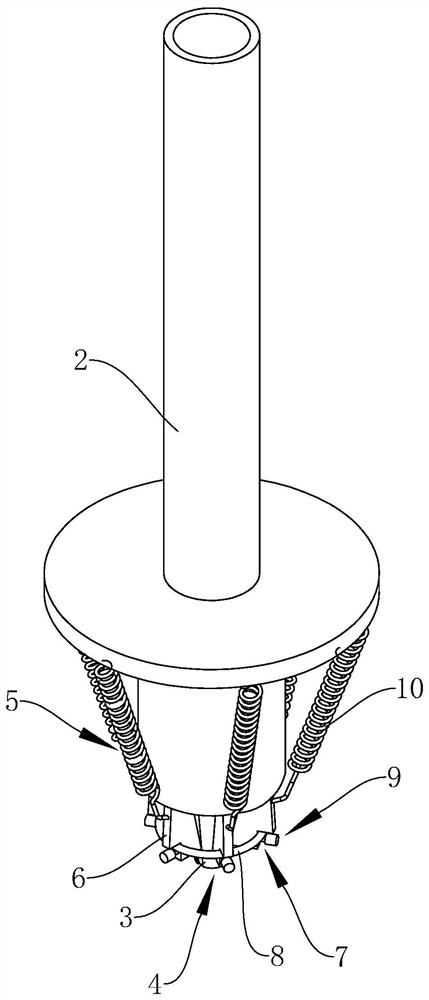

[0043] The following is attached Figure 1-5 The application is described in further detail.

[0044] The embodiment of the application discloses a processing technology of a die casting and a cutting system thereof.

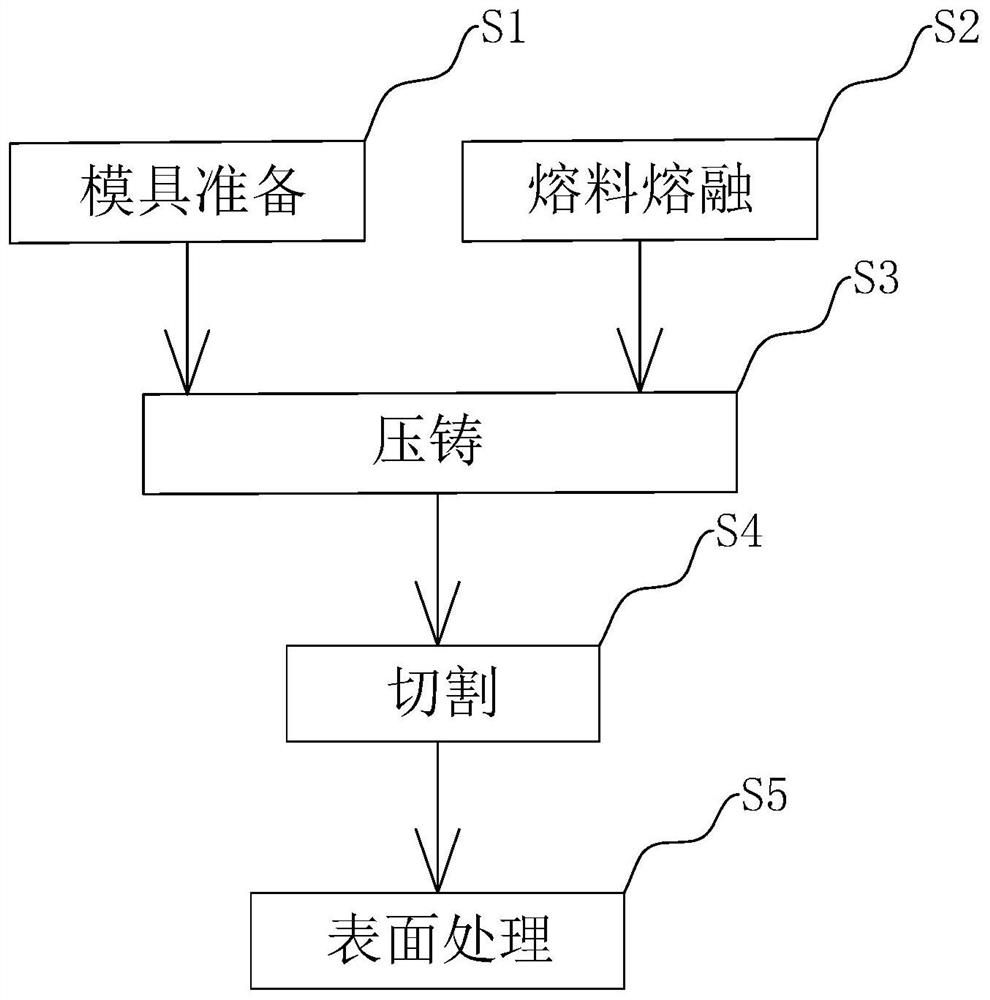

[0045] refer to figure 1 , a processing technology of die castings comprises the following steps:

[0046] S1. Mold preparation process, replace the suitable mold, preheat the mold and spray the release agent;

[0047] S2. Melting material melting process, using a melting furnace to melt solid metal to obtain liquid metal;

[0048] S3. Die-casting process, the mold in the S1 step is pumped to form a negative pressure in the mold, and the liquid metal obtained in the S2 step is absorbed into the mold under the connection of the injection pipe, and the cavity in the mold is completely Filling, the mold performs die-casting on the liquid metal to obtain die-casting parts;

[0049] S4. Cutting process, the die-casting is removed from the mold, and the die-casti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com