Method of organizing polymer porous support material for engineering and its preparation device

A porous scaffold and tissue engineering technology, applied in the field of preparation of polymer porous bodies, can solve the problems of porogen residue, donor source, immune rejection, etc., and achieve the effect of simple manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

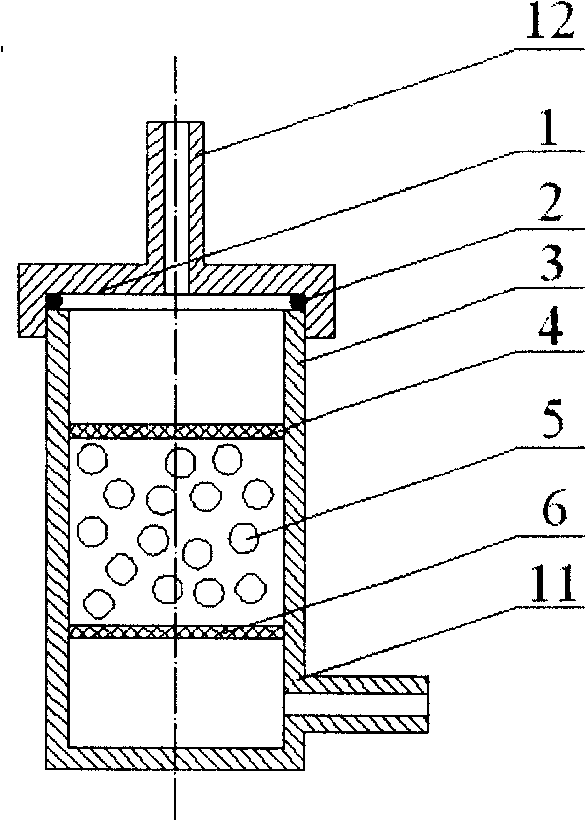

[0018] 1) Put the ice particle porogen 5 with a particle size in the range of 300-400 μm through a standard sieve into the cylindrical mold 3, and gently tap the wall of the cylinder with a wooden hammer or a nylon rod to make the ice particles tightly packed;

[0019] 2) Prepare polylactic acid (PLA) / chloroform solution at a ratio of 1:10, and pre-cool at -20°C;

[0020] 3) Inject the pre-cooled polylactic acid (PLA) / chloroform solution into the upper space of the compression net 4 in the cylindrical mold 3, vacuum through the vent hole 11, and the solution percolates into the pore-forming area under a pressure of 0.002-0.02 MPa. The gap between agent 5 is then frozen and formed in liquid nitrogen to obtain a prefabricated block containing polymer, solvent and ice;

[0021] 4) The prefabricated block obtained above is freeze-dried in a self-made freeze-drying device at -55~61°C, removes the solvent, then slowly raises the temperature, and keeps it below 0°C for an appropriate...

Embodiment 2

[0023] 1) Put the ice particle porogen 5 with a particle size in the range of 800-900 μm through a standard sieve into the cylindrical mold 3, and gently tap the wall of the cylinder with a wooden hammer or nylon rod to make the ice particles tightly packed;

[0024] 2) Prepare polylactic acid (PLA) / chloroform solution at a ratio of 1:8, and pre-cool at -20°C;

[0025] 3) Inject the pre-cooled polylactic acid (PLA) / chloroform solution into the upper space of the compression net 4 in the cylindrical mold 3. After the cover 1 is installed, the high-pressure gas is passed through the vent hole 12, and the pressure is 0.5-1.5MPa. The solution seeps into the gap of the porogen 5 under a pressure of 100%, and then freezes and shapes in liquid nitrogen to obtain a prefabricated block containing a polymer, a solvent, and ice;

[0026] 4) The prefabricated blocks obtained above are freeze-dried at - (55-61)°C in a self-made freeze-drying device to remove the solvent, then slowly raise ...

Embodiment 3

[0028] 1) Put the ice particle porogen 5 with a particle size in the range of 800-900 μm through a standard sieve into the cylindrical mold 3, and gently tap the wall of the cylinder with a wooden hammer or nylon rod to make the ice particles tightly packed;

[0029] 2) Prepare poly-3-hydroxybutyrate (PHB)-chloroform solution at a ratio of 1:5, and pre-cool at -20°C;

[0030] 3) Inject the pre-cooled poly 3-hydroxybutyrate (PHB) / chloroform solution into the upper space of the compression net 4 in the cylindrical mold 3, and after the cover 1 is installed, vacuumize through the air hole 11, at 0.005-0.04 Under the pressure of MPa, the solution seeps into the gap of the porogen 5, and then freezes and shapes in liquid nitrogen to obtain a prefabricated block containing a polymer, a solvent, and ice;

[0031] 4) The prefabricated block obtained above is freeze-dried in a self-made freeze-drying device at -55~61°C, removes the solvent, then slowly raises the temperature, and keeps...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com